PP hollow board

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Delivery Time:

- 7 Days

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

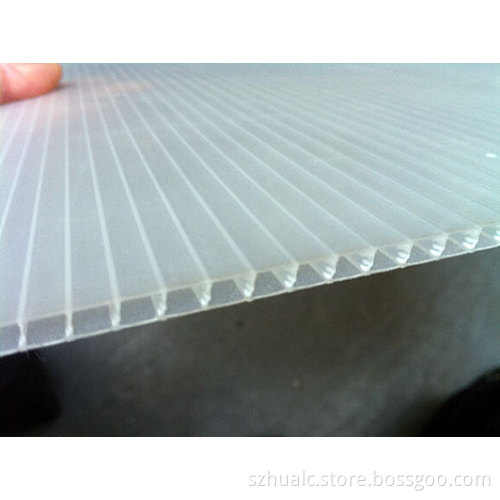

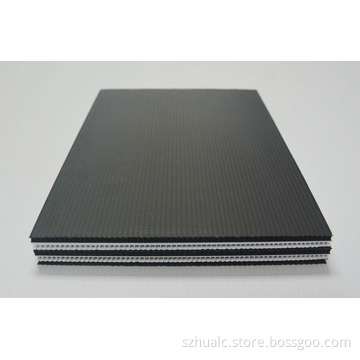

The hollow board products have the advantages of shockproof, flexible design structure and no need to open injection molds. Recyclable to reduce packaging shipping costs. Defective products can be repaired and cured, and scrap products can be recycled. At the same time, the plate can be flexibly added with antistatic, conductive masterbatch, etc. to produce a plastic hollow board with conductive and antistatic functions. The surface resistivity of the antistatic sheet can be controlled to the 6th power of the 10 hollow board. ~10 between the 11th power. The surface resistivity of the static conductive sheet can be controlled between 10 and 3 to the 5th power.

Hollow plates and their deep processing products are used in a wide range of fields, and the fields that have been developed and used are:

1. Industrial product packaging turnover: electronic component packaging turnover box, plastic parts turnover box, logistics transportation folding turnover box.

2, luggage handbags: luggage liners, pads, pallets, partitions.

3, bottle industry: glass bottle factory pad, bottle holder, canned product separator, can tray, pad.

4. Machinery industry: machine cushion plate.

5, advertising industry: advertising board, sign board, corona board, fire-retardant board, color printing board, display box, display stand.

6, home decoration: ceiling, decoration protection board.

7, furniture industry: coffee table pad, furniture decorative board.

8, the agricultural industry: a variety of fruit boxes, vegetable crates, beverage crates, food crates.

9, stylistic products: smart blackboard, file bag.

10, the automotive industry: steering wheel pad, rear partition, pad.

11, electrical industry: refrigerator washing machine air conditioner purifier back plate, partition.

12, baby products: baby carriage pad, children's intelligent hurdles.

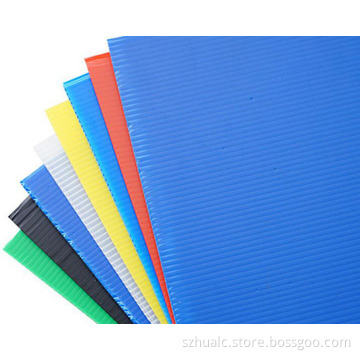

The hollow board raw material is PP plastic, which is polypropylene plastic, which is non-toxic. The processing temperature (°C) during manufacture is 180-240, so boiling water will not decompose it, and it will not harm the human body. Different colors can be produced according to the requirements. By adding flame retardant, the hollow board produced can achieve the flame retardant effect and can be extinguished.

Related Keywords