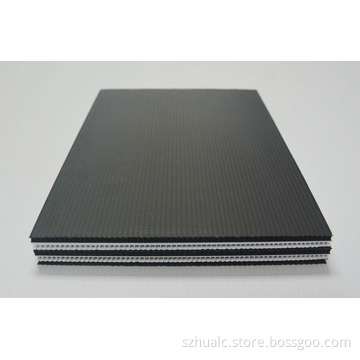

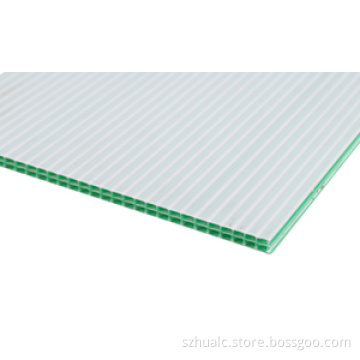

2.5mm corflute 2.4m x 1.2m floor protection

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

Product Description

Product Description

The working process of the 2.5mm corflute 2.4m x 1.2m floor protection

mold closing→HP mold locking at low speed→moving the injection mount forward→injecting the melt→pressure-holding→the melt in the mold cooling(At the same time, plastified ?threaded rod step back with the injection mount, threaded rod revolve the plastic materials)→the forming material in the mold cooling and solidifying→opening the mold, putting the product out of the mold→closing mold(the next product begin being produced)

The amount of materials of the 2.5mm corflute 2.4m x 1.2m floor protection is according to the product. Putting the material into the injection machine, the threaded rod move the material forward, and then heating the material. Because the material have to be heated and compressed, gradually, the material become molten.

As for the molten material in the forepart of the threaded rod, because of the resistance of the nozzle, create the pressure of against the threaded rod. With the increasing amount of molten material which pushed by the threaded rod, the back pressure is increasing also. When the back pressure is greater than the thrust and friction of the oil cylinders to the threaded rod. The threaded rod begin stepping back and adding material into the hopper. When the threaded rod touch the switch, the machine stop moving, finishing the process of plastifying the material.

mold closing→HP mold locking at low speed→moving the injection mount forward→injecting the melt→pressure-holding→the melt in the mold cooling(At the same time, plastified ?threaded rod step back with the injection mount, threaded rod revolve the plastic materials)→the forming material in the mold cooling and solidifying→opening the mold, putting the product out of the mold→closing mold(the next product begin being produced)

The amount of materials of the 2.5mm corflute 2.4m x 1.2m floor protection is according to the product. Putting the material into the injection machine, the threaded rod move the material forward, and then heating the material. Because the material have to be heated and compressed, gradually, the material become molten.

As for the molten material in the forepart of the threaded rod, because of the resistance of the nozzle, create the pressure of against the threaded rod. With the increasing amount of molten material which pushed by the threaded rod, the back pressure is increasing also. When the back pressure is greater than the thrust and friction of the oil cylinders to the threaded rod. The threaded rod begin stepping back and adding material into the hopper. When the threaded rod touch the switch, the machine stop moving, finishing the process of plastifying the material.

Related Keywords

Related Keywords