Laboratory equipment - plating bath.

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 5 Days

- Transportation:

- Ocean

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000Sets |

| Supply Ability: | 100000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | CE |

| Transportation: | Ocean |

| Port: | Shenzhen,Guangzhou,HongKong |

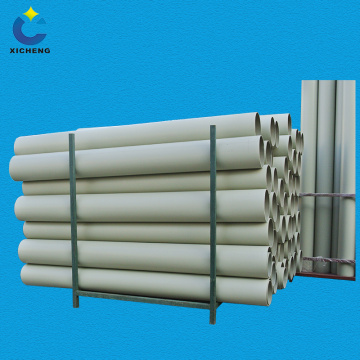

Electroplating bath is the most common sink and acid bath in electroplating equipment. The material is made of PP material and steel structure. The plating bath can be used for galvanizing, copper plating, nickel plating and gold plating. The cathode mobile electroplating bath is composed of a groove, a conductive device, a steam heating tube and a cathode mobile device.

The characteristics of

1. To meet the electroplating requirements of the machining parts, and to fully immerse the entire surface of the parts required for electroplating;

2. Maintain the stability of electrolyte composition in the electroplating production cycle.

3. At the same time, the overall coordination of the production line should be taken into consideration to meet the rationality of the layout of the electroplating workshop.

We can design and customize the tank according to the drawing or customer requirements, and the selection of the tank structure depends on the nature and temperature of the plating bath. It consists of a tank, a solution heating and cooling device, a conductive device, an electric motor, a reducer, an eccentric disc, a connecting rod and a pole supporting roller.

The characteristics of

1. To meet the electroplating requirements of the machining parts, and to fully immerse the entire surface of the parts required for electroplating;

2. Maintain the stability of electrolyte composition in the electroplating production cycle.

3. At the same time, the overall coordination of the production line should be taken into consideration to meet the rationality of the layout of the electroplating workshop.

Related Keywords