Abs injection molding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 49 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K Mold group is a creation team compose of young professionals from different industries, concertrates on offering customers business creation and value-added service via our core power of products design,design and manufacture of molds, as a professional enterprise for design and manufacture creation,and therefore accumulated rich experience and commercial resource in the industries of Automotive, Electronics and Home appliances.

3K Group position itself as "Systematic Creation Organization", we use our advantage of design and manufacture of plastic injection mould, to realize the value of 3K team in there areas include continuous offering customer product design service, assisting our clients decrease the cost for mold development, reduceing the of cycle time of project development.

We have good product designers and mold designers, forward-looking design culture,creative design thinking,rich experience for manufacturability,machining and prodction,complete supply chain from product design, to molds development,then injection molding, until semi-finished plastic products.

We continuously improve products chain,in order to offering our clients more efficient,more professional service.

Our service includes(but not limited): Product moldeling and design, prototype machining,small quantity production, product reverse engineering, tooling manufacturability.

| Project Information | ||

| Product Description | Part Name | Household appliance components |

| Part Material | ABS | |

| Part Size(mm) | 590*50*30 | |

| Mould Description | Cavity Insert Material | 2343 HRC48-52 |

| Core Insert Material | 2343 HRC48-52 | |

| Slider Insert Material | ||

| Mould Cavities | 2 | |

| Mold parts Standard | Hasco | |

| Mold Size | 850*450*540mm | |

| Mold weight | 1498kg | |

| Lead time | ||

| Mould Life Time (Shots) | 1000K | |

| Mould Type | Export to poland | |

| Runner Description | Cold runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | Ejector pin | |

| Surface finish | ||

| Slide Qty. | 0 | |

| Lifter Qty. | 4 | |

| Injection moulding machine | 300T |

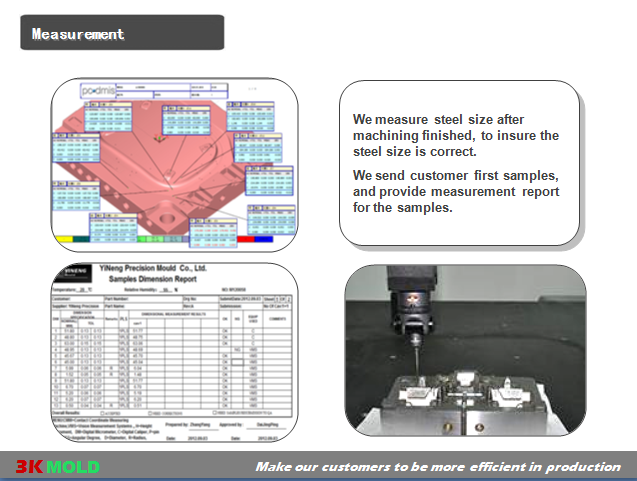

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

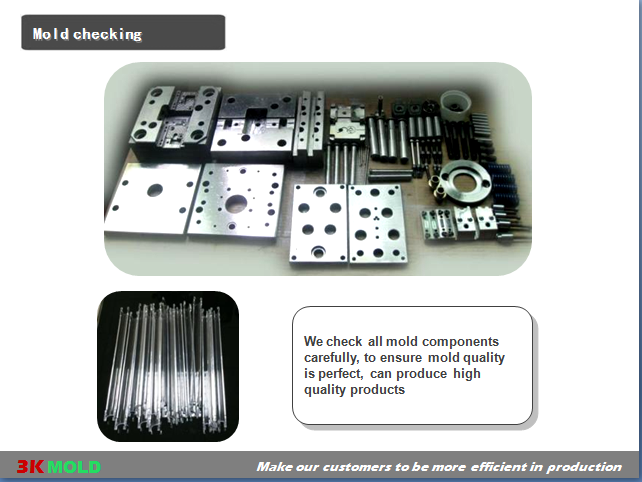

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Arburg 3201.2343 ESU

HRC48-52