Switch Cover Injection Mould

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 42 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

The Advantages of 3K Mold

Speed – plastic injection moulding is a fast production method. Cycle times can be as short as a few seconds depending upon the component being moulded.

Cost – plastic injection moulding allows for mass production on a very cost-effective scale.

Quality – injection moulded components can be produced to very high levels of precision, and with minimal finishing requirements.

Efficiency – injection moulding of plastic wastes very little raw material as scrap can be melted and recycled.

Simplify – the injection moulding process can often reduce the number of components required to make a product, and therefore reduce assembly time.

If you are interested in, please feel free to contact us.

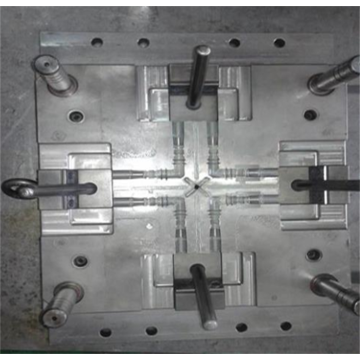

| Project Information | ||

| Product Description | Part Name | Switch Cover Injection Mould |

| Part Material | ABS | |

| Part Size(mm) | 108x76x19mm | |

| Mould Description | Cavity Insert Material | H13 HRC 48-52 |

| Core Insert Material | H13 HRC 48-52 | |

| Mould Cavities | 1 | |

| Mold parts Standard | Hasco | |

| Mold Size | 300X300X320mm | |

| Mold weight | 209 kg | |

| Lead time | 6 weeks | |

| Mould Life Time (Shots) | 500K | |

| Mould Type | Export to Poland | |

| Runner Description | Cold runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | Ejector pin | |

| Slide Qty. | 2 | |

| Lifter Qty. | 0 | |

| Surface finish | Polish | |

| Injection moulding machine | 80T |

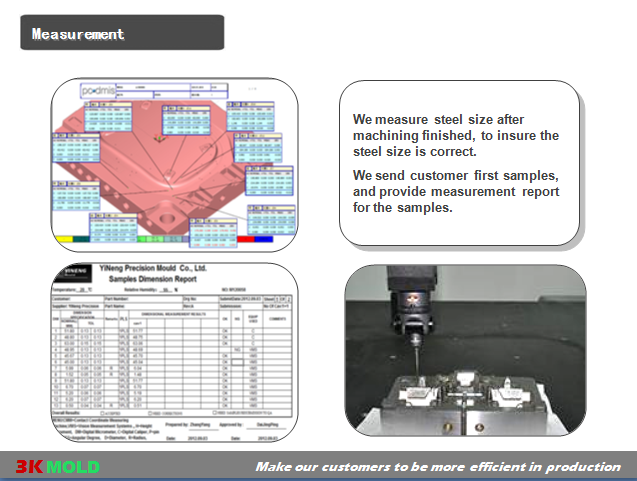

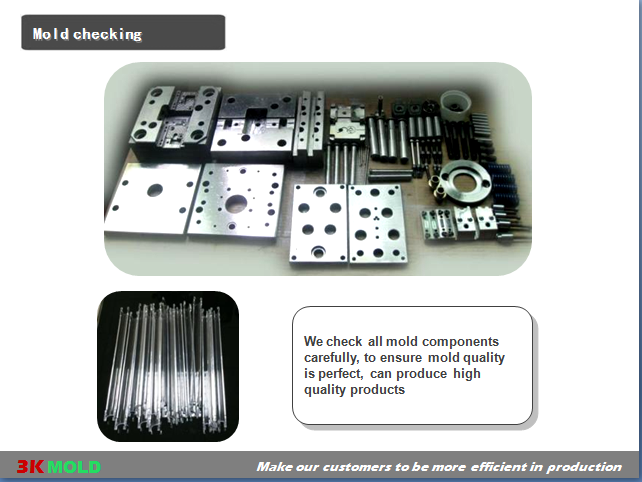

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords