TOYOTA Car Inner Molding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K Mold`s manufacturing assets are focused on building Plastic Injection Molds. We leverage the accuracy of Mori Seiki 850 CNC to build injection molds with tight tolerances. Our technology and proprietary processes allow us to build accurately and continuously which increases mold and part quality, reduces mold build leadtime and mold cost.

Each new mold project is assigned a Project Manager for single point of contact. Our 26 step Product Development Process ensures you are involved as little or as much as you want during the build and final process review.

We are not satisfied with delivering only a mold, with all new mold builds 3K Mold will sample and ensure the mold produces components in an efficent process. It takes the guess work out of starting production at your facility.

All molds are 100% guaranteed while running production in our facility.

Let us put our technology to work for you today!

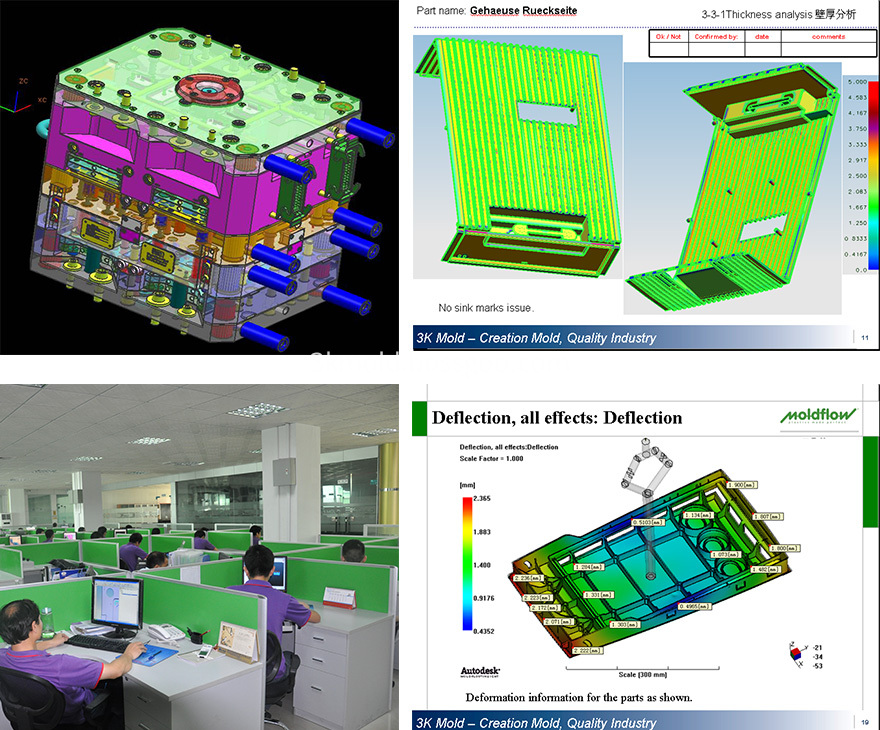

High quality mold starts with a high quality design.

Before mold machining, Engineering will provide a DFM report to analysis potential issue such as injection gate type and position, Mold layout, Ejector pins layout, draft analysis, thickness analysis, part warpage, sink marks and surface finish etc. If necessary, We also provide the mold flow analysis report to analysis the filing, pressure, weld line, airtrap, deflection etc. To discuss with customer and determine the final mold concept. After providing the 3D/2D for final approval.

At 3K Mold Group, our design team consists of 15 skilled designers. They knew Hasco, DME and Custom standard etc Europe andAmericamold standard very well. Equipped with the latest hardware and software CAD, CAE,CAMto assist mold design and manufacturing. Rely on advanced equipment and 20 years experience in mold industry. 3K Mold Group has been built a diversified customer base from different industry.

Related Keywords