Plastic Injection Mold For Auto Accessory Tools

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K MOLD has produced custom-molded products for a wide variety of industries, including; automotive, consumer, and office equipment firms. We believe in being a full-service provider who ensures a thorough product development process; from initial concept through production to delivery.

We create a computerized 3D solid model of your product. We consider all your manufacturing and marketing requirements, when creating the initial sample. We consult with you to ensure our cutting-edge solutions meet and exceed your manufacturing needs.

Design concepts can be sent to us in a wide range of file formats, including; Unigraphics, IGES, DXF, DWG and CADL. We can also create designs based upon a sample or model.

We believe that a quality product is a direct result of precision design. Throughout the concept to design process, we make sure that you are fully informed of all components of product development.

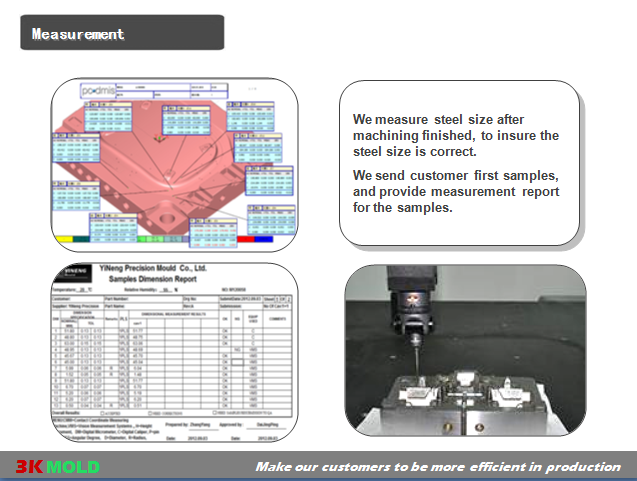

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

3. Mold component inspection

4. Electrodes inspection

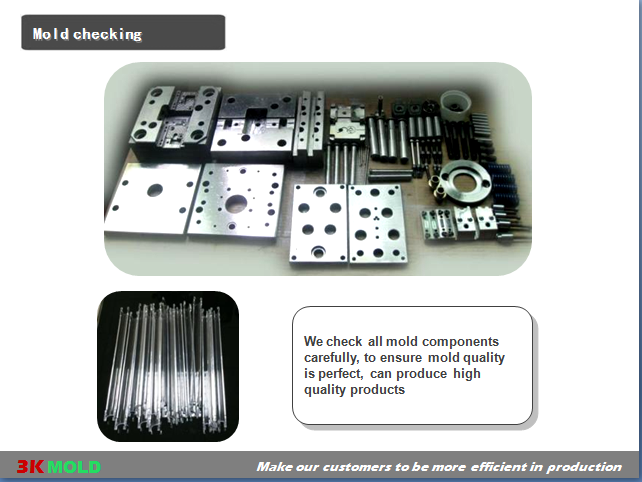

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords