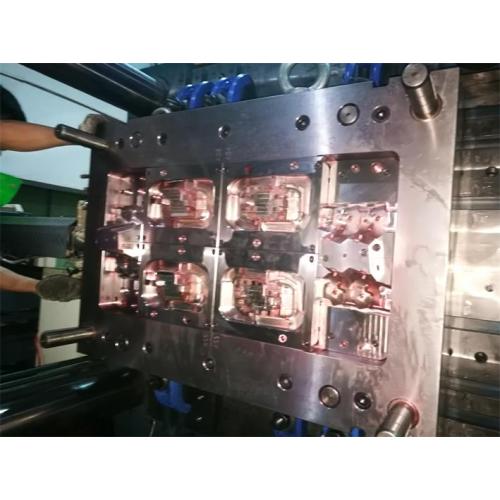

Automotive filling part 2K molding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 70 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

In order to make good service and big capacity for our customer,3K Mold introduced 2K injection machine and double heads EDM machine, Equiped with 120 workers, 30 engineers, 12 CNC machines, and 8 EDM machines.

Our annual manufacturing capacity is between 300-500 molds exporting mainly to Europe, America. Our molds and moldings are made for the Automotive, Consumer Electronics, Home Appliances, Packaging and Medical Industries etc.

Meanwhile, 3K continuously focus on improving our people, performances and invest in the latest machining facilities and technologies. Always we explore every opportunity to provide a most satisfactory product to our customers and increase our customers' satisfaction on every project.

With world-class quality and manufacturing standards, state of the art equipment and whole dedicated staff, we are positioned to provide the best service for our worldwide customers, supporting you to be the leader in the industry.

|

|

|

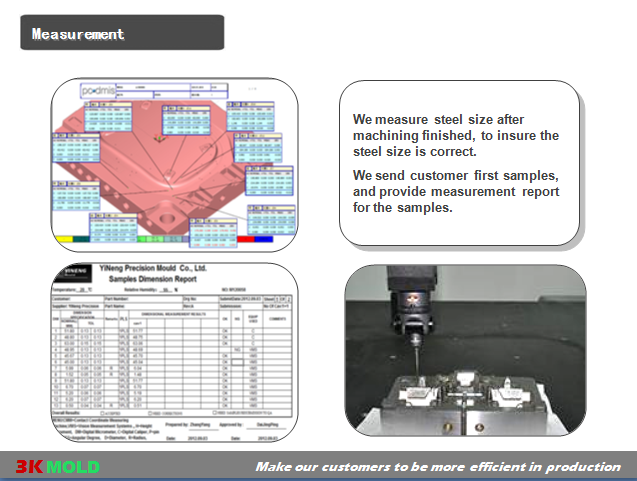

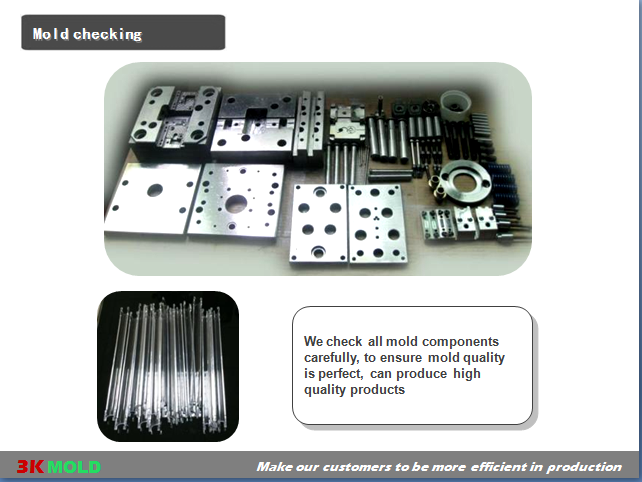

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords