Gas switch sealing over molding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

Our highly skilled employees are familiar with hot runner systems, reverse ejection and two-stage ejection. The team's innovative problem solving technical support provides our customers with cost-efficient solutions. 3K Mold's exceptional skill and vision in the plastics industry drives our ability to build quality tools for 2K Parts. With this unique knowledge, we can enhance performance and reliability on every plastics mold we build.

Your multi-material product should be built by one mold maker. Knowing what is vital on each part and how they must interact with each other is crucial in secondary processes. With our vast knowledge of both thermoplastic and thermosets, we will take away that worry by building all components at 3K MOLD.

All of our tools are built to SPI standards using only the best steels and components available for industries, including but not limited to, medical, automotive, household appliances and consumer products.

| Project Information | ||

| Product Description | Part Name | Gas switch sealing over molding |

| Part Material | PP GF30+TPE | |

| Part Size(mm) | 50.5x51x32 | |

| Mould Description | Cavity Insert Material | 1.2344 ESU HRC48-52 |

| Core Insert Material | 1.2344 ESU HRC48-52 | |

| Slider Insert Material | 1.2344 ESU HRC48-52 | |

| Mould Cavities | 1+1 | |

| Mold parts Standard | Hasco | |

| Mold Size | 346x312x403mm | |

| Mold weight(KG) | 300 | |

| Lead time | 5 weeks | |

| Mould Life Time (Shots) | 1000K | |

| Mould Type | Export to Austria | |

| Runner Description | Synventative | |

| Injection Gate Type | Banana gate | |

| Ejection System | Ejector pin | |

| Surface finish | VDI 3400-CH24 | |

| Slide Qty. | 4 | |

| Lifter Qty. | 0 | |

| Cycle time | 30 S | |

| Injection moulding machine | 100T |

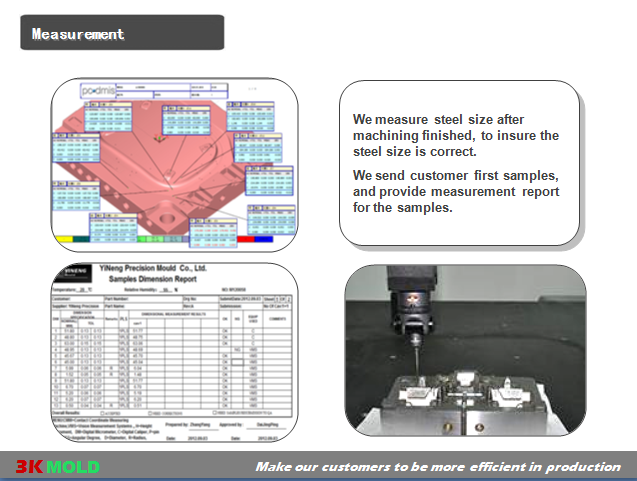

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

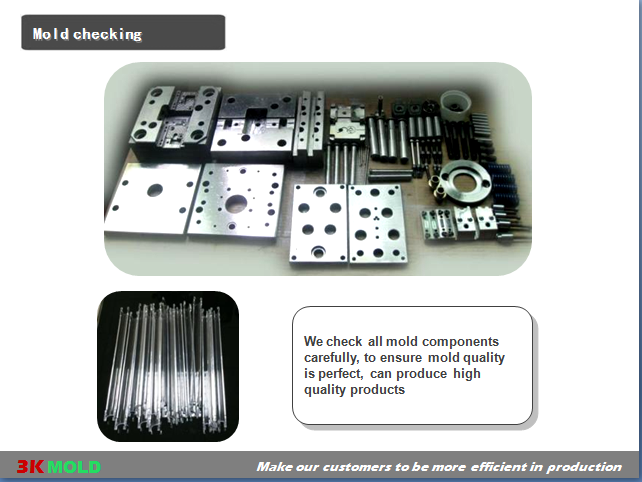

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords