Slider And Lifter In Mold

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001 |

| HS Code: | 84804100 |

| Transportation: | Air |

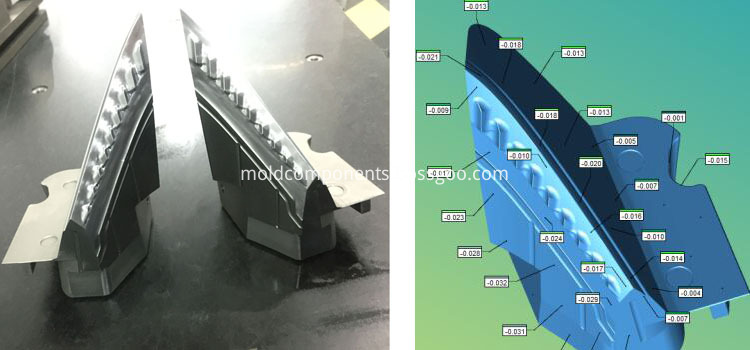

Slider And Lifter In Mold

The development cycle of a product is each time shorter. Gathering as one single team the Product Engineering, the Rapid Prototyping, the Prototype molds and the production molds, appears Hongzhun technology .

Giving support on creation and design, virtual simulation, models and

functional prototypes manufacturing, Hongzhun technology helps you to shorten this

cycle. The main goal of Hongzhun technology is to improve engineering,

fabrication and commercialisation of plastic prototypes and injection

molds, all this in a very short time. The specialisation of each one of the production units of Hongzhun technology is fundamental for all

this:

- Product Development; Rapid Prototyping ; prototype molds; small series production;mold components, such as Injection Molding Slider Mechanism, Lifters In Injection Molding.

- High precision molds.

- Surface finish treatments.

Hongzhun technology will be your partner in any

place of the world!

Description:

Process tolerance: +/-0.01mm

Manufacturing Lead time: 10 days

Delivery lead time: 3 days

Size: 40x35x45mm

Material: 1.2343

Hardness: 52+2 HRC

ISO 9001 certified

Lifters In Injection Molding for automotive industry

HS code: 84804100

Advantage:

- Quality: it is life of company. we have been working with our customer from USA and Europe for more than 10 years .

- Price/leadtime: it is power to develop the company, we can provide the best price with leadtime.

- Service/communication---it is keeping good relationship.

- We are interesting on making Auto mold, Home appliance and other plastic mold.

New Trend:

In order to improve the tooling process capacity and save the cost on transportation,

more and more customers are going to use the new way to reach the goal.

They only building the precision tool components in china, such as, lifters, sliders, core&cavity

inserts etc. But assemble and production in their country.

Related Keywords