Machining Small Metal Parts

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Air

- Port:

- Shenzhen, Hongkong, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Supply Ability: | 200 PCS/Month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001 |

| HS Code: | 84804100 |

| Transportation: | Air |

| Port: | Shenzhen,Hongkong,Guangzhou |

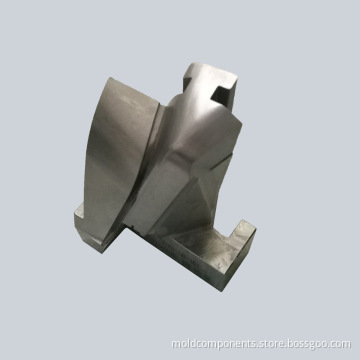

Machining Small Metal Parts

Since 2009, Hongzhun technology have been working in partnership with his clients, in the framework to exceed your expectations in the production of moulds & mould components for the plastic industry.

We are Equipped with the most modern high-tech machinery, associated to powerful and sophisticated CAD/CAM software`s. Together with the commitment and professionalism of its employees, Hongzhun technology is able to project and develop moulds followed by high standards of accuracy and precision throughout their developments for many different industry areas, we have the know-how in order to apply in new projects.

In Hongzhun technology the innovation, the development, the quality and the rigorous deadline accomplish in partnership with their clients are a constant to achieve the expectations with maximum precision, professionalism and transparency.

Contact us and bring your challenges.

Description:

- Process tolerance: +/-0.01mm

- Manufacturing Lead time: 5 days

- Delivery lead time: 3 days

- Size: 25X35X25mm

- Material: 1.2343

- Hardness: 52+2 HRc

- ISO 9001 certified

- Custom CNC Machining for mold insert

- HS code: 84879000

Advantage:

- Show your customers and investors a model of your product

- Demonstrate the appearance, dimensions and features of your product

- Test your design for its suitability

- Save time and money by identifying and reducing design flaws

- Improve and streamline the production process

- Reduce your work load when the time comes to manufacture

- Create multiple versions with different colors, surface textures and finishing processes

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.

Company Image:

At HZ, we use Hi-speed CNC machine center, Sodick slow-feeding-wire-cut, Sodick mirror EDM and CMM machine checking every process to provide accuracy and precision when making your CNC Machining parts & Mold Components. Our professional and aspiring team of engineers and technicians work in a clean and tidy environment use the advanced equipment, to turn your concepts into reality quickly, accurately and at a great price. You design it and we will make it.

Office and Design Department

High-speed CNC machine

Precision EDM and Wire-EDM

Inspection Department

Related Keywords