Plastic Injection Mould Insert

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 18 Days

- Transportation:

- Air

- Port:

- Shenzhen, Hongkong, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001 |

| HS Code: | 84807190 |

| Transportation: | Air |

| Port: | Shenzhen,Hongkong,Guangzhou |

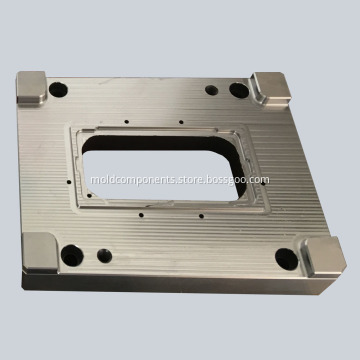

Plastic Injection Mould Insert

Product Name: Plastic injection mold cavity insert With the Best Quality

Material: Steel, aluminum, stainless steel and so on.

Precision machine: Driling, Milling, CNC Turning, Grinding, Wire cutting, EDM& etc.

Applied software: PRO/E, Auto CAD, Solid Works, UG, CAD/CAM/CAE

Surface finish: Anodize; Polishing; Zinc/ nickel/chrome/gold plating, Sand blasting&etc.

Dimension: As per customer's request

Tolerence : +/-0.002-0.02mm/ can also be customized

Quality system: 100% inspection before shipping

Packing: Eco-friendly pp bag/ carton box or wooden box;As customer's specific requirements

Shipping: By sea, By air, By DHL, UPS, FEDEX&etc.

Description:

- Process tolerance: +/-0.01mm

- Manufacturing Lead time: 18 days

- Delivery lead time: 3 days

- Size: 250x200x45mm

- Material: 1.2311

- Hardness: 290-330 HB

- ISO 9001 certified

- Mold Tool Slider for Injection Mold

- HS code: 84807190

Advantage:

- Show your customers and investors a model of your product

- Demonstrate the appearance, dimensions and features of your product

- Test your design for its suitability

- Save time and money by identifying and reducing design flaws

- Improve and streamline the production process

- Reduce your work load when the time comes to manufacture

- Create multiple versions with different colors, surface textures and finishing processes

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.

Company Image:

At HZ, we use Hi-speed CNC machine center, Sodick slow-feeding-wire-cut, Sodick mirror EDM and CMM machine checking every process to provide accuracy and precision when making your CNC Machining parts & Mold Components. Our professional and aspiring team of engineers and technicians work in a clean and tidy environment use the advanced equipment, to turn your concepts into reality quickly, accurately and at a great price. You design it and we will make it.

Office and Design Department

High-speed CNC machine

Precision EDM and Wire-EDM

Inspection Department

Related Keywords