OEM Carbon fiber Helicopter mutilators

-

$10.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 20000 |

| Supply Ability: | 20000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

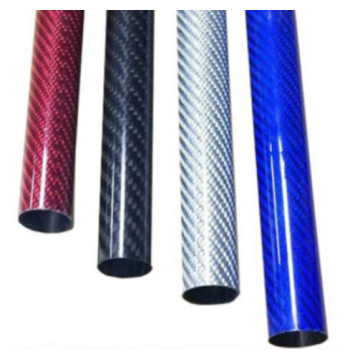

In the fast-paced aviation world, innovation is key, and our OEM Carbon fiber Helicopter Rotors are leading the charge. Having witnessed their production up close, I can attest to the exceptional craftsmanship enabled by advanced Cnc Carbon Fiber Cutting techniques. These rotors aren't just parts—they're game-changers setting new industry standards.

Performance That Stands Out

The first time I handled one of these rotors, I was immediately struck by its perfect balance of lightness and sturdiness. Thanks to Cnc Router Carbon Fiber Cutting Frames technology, the precision in its design is remarkable. When we replaced old metal rotors with these carbon fiber ones in a project, the transformation was dramatic. The helicopter became more responsive, consumed less fuel, flew faster, and executed agile maneuvers with ease—much like how Cnc Drone Frames and Cnc Carbon Fiber Frames enhance drone performance.

But their strength is equally impressive. During a storm test flight, while other helicopter components rattled, these rotors held firm. They're built to withstand extreme vibrations and debris impacts, a testament to the precision Cnc processes used in their creation. Unlike metal rotors prone to corrosion, especially in salty or chemical-laden environments, our carbon fiber rotors maintain peak performance over years, thanks to manufacturing techniques similar to those for Cnc Drone Frames and Cnc Carbon Fiber Frames. This means fewer repairs and less downtime for operators.

Where They Excel

Military Missions

In military operations, every second and ounce matters. These lightweight rotors, crafted with precision Cnc Carbon Fiber Cutting, enable faster troop deployment and longer flight times. In combat zones, their strength from Cnc Router Carbon Fiber Cutting Frames ensures they endure rough landings and evasive maneuvers. Their corrosion resistance is invaluable across diverse climates, mirroring the reliability of Cnc Carbon Fiber Frames and Cnc Drone Frames.

In military operations, every second and ounce matters. These lightweight rotors, crafted with precision Cnc Carbon Fiber Cutting, enable faster troop deployment and longer flight times. In combat zones, their strength from Cnc Router Carbon Fiber Cutting Frames ensures they endure rough landings and evasive maneuvers. Their corrosion resistance is invaluable across diverse climates, mirroring the reliability of Cnc Carbon Fiber Frames and Cnc Drone Frames.

Search and Rescue

When lives are at stake, reliability is crucial. Cnc Carbon Fiber Cutting precision allows these rotors to quickly reach remote areas, while their Cnc Drone Frames - inspired design helps pilots navigate tough terrains. Rescue teams trust these rotors to perform under pressure, whether rescuing stranded individuals or delivering emergency supplies.

When lives are at stake, reliability is crucial. Cnc Carbon Fiber Cutting precision allows these rotors to quickly reach remote areas, while their Cnc Drone Frames - inspired design helps pilots navigate tough terrains. Rescue teams trust these rotors to perform under pressure, whether rescuing stranded individuals or delivering emergency supplies.

Civilian Flights

For tour and business travel, these rotors enhance the passenger experience. Precision construction from Cnc Carbon Fiber Cutting and Cnc Router Carbon Fiber Cutting Frames reduces vibration, offering a smooth, quiet ride. With Cnc Drone Frames - like low maintenance, operators keep helicopters in the air more, boosting revenue, while the rotors' sleek look adds luxury.

For tour and business travel, these rotors enhance the passenger experience. Precision construction from Cnc Carbon Fiber Cutting and Cnc Router Carbon Fiber Cutting Frames reduces vibration, offering a smooth, quiet ride. With Cnc Drone Frames - like low maintenance, operators keep helicopters in the air more, boosting revenue, while the rotors' sleek look adds luxury.

Offshore Operations

Offshore, where saltwater and harsh conditions degrade traditional rotors, ours thrive. Advanced Cnc techniques, similar to those for Cnc Drone Frames and Cnc Carbon Fiber Frames, keep them in top shape. I've seen rotors on oil rigs running perfectly for years, ensuring supply chain reliability and worker safety.

Offshore, where saltwater and harsh conditions degrade traditional rotors, ours thrive. Advanced Cnc techniques, similar to those for Cnc Drone Frames and Cnc Carbon Fiber Frames, keep them in top shape. I've seen rotors on oil rigs running perfectly for years, ensuring supply chain reliability and worker safety.

Related Keywords

Related Keywords