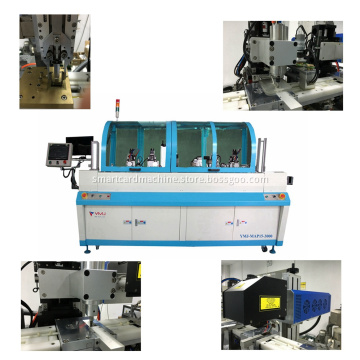

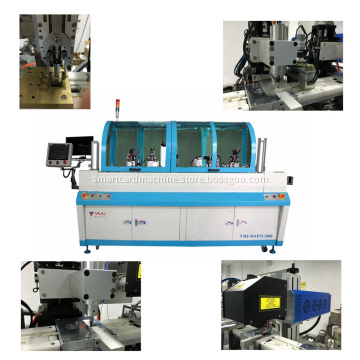

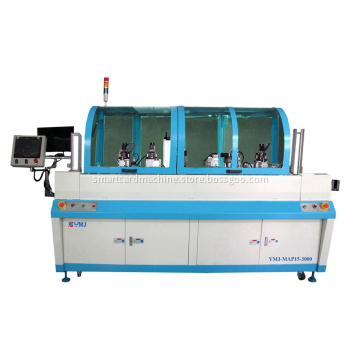

Automatic multi-function magnetic strip mounting machine

Your message must be between 20 to 2000 characters

Contact NowMain function:

This machine incorporates multi-function of automatic magnetic strip peeling, automatic trimming, automatic collecting, magnetic strip mounting on sheets & magnetic strip mounting on film;

Features

Controlled by PLC, touched screen and friendly interface.

Feeding material by servo motor, running speed and roll sheet length can be controlled.

Use double cylinders as motivity, the pressure of the welding spot can be adjusted. The magnetic stripe welding spot is level off and firmed.

Roll overlay is cut by cylinder driving; its structure is simple and stable.

Waste magnetic strip material collected automatically, it is suit for regular magnetic strip and stripped magnetic strip.

Used pneumatic shaft material collecting system to make roll overlay feeding and loading easier operating.

Heating temperature control method: use the heater to heat up and the imported thermocouple cooperating with temperature controller to control the temperature, it is easy to set and the temperature controller is precise.

Each mounting head can be adjusted temperature and pressure.

Used automatic tension control system to feed material, ensure roll overlay feeding smooth and stable.

It can realize the magnetic processing of the roll to sheet or the sheet to the sheet.

Can through hot pressing rolling method mount magnetic strip onto the film; also can directly mount it onto PET, PVC sheets;

Automatic magnetic strip peeling off, scrap collecting.

Slice film length can be set freely

Rolling the magnetic stripe into the film by hot pressing, or you can choose to directly slap on PET, PVC and other sheets.

Sheet cutting accuracy: ±1mm

Technical parameters:

Machine overall dimension: Approx. L2800×W1400×H1900mm

Electric cabinet dimension: Approx. L750×W400×H1650mm

Weight: Approx 1400Kg

Power supply: AC 380V 50/60 HZ

Air source: 6 Kg/C㎡((No Water) ( moisture filter)

Total power: 6.0KW

Air-flow: 5 Litter/minute

Low-Air Alarm: 4 kg /c㎡

Available material: accord with ISO/IEC7811 high density and lower density magnetic stripe

Stripe width: 12.7mm 6.35mm plate dia.380mm

Stripe width range under 12.7mm ~6.35mm can use this machine

Stripe amount 5~8PCS

Available sheet: 3X8

Operator: 1 person

Available material:

Film sheet: thickness0.25~0.8mm; Max. Width: 580mm.

Coil film: thickness0.04-0.18mm; Inner Diameter:3 Inches; Outer diameter less than 20inches[500mm]; Max width: 580mm.

Temperature control range: 0-400℃(With Choice)

Temperature control precision: ±4℃

Laying precision: ±0.15mm

Unloader Capacity: about 20 pcs sheet, the operator can sort out, because too many sheets will bring mess.

Yield: 99% (defined as GOOD sheets / total sheets produced)

Output: 3-4 Meters/minute( From roll to roll) ; Min. 400 sheets/h ( From roll to sheet)

Ion Pump for removing for static removal.

Related Keywords