Single Core Milling and Chip Embedding Equipment

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 35 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO, CE |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN |

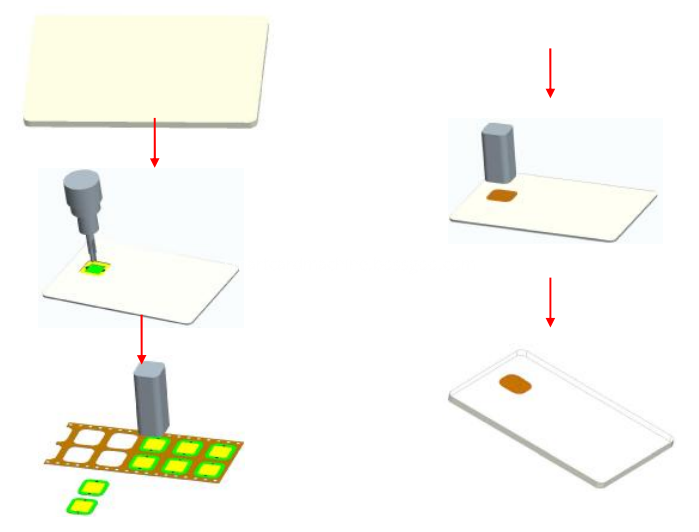

Single Core Milling and Chip Embedding Equipment can help smart card manufacturer mill cavities automatically and finish embedding and welding of chips. This model of milling and embedding machine is controlled by PC, which allows more designs with higher precision.

There are one card feeding magazine and two card collecting magazines, while two card collecting magazines can collect smart cards alternatively.

This model of milling and chip embedding equipment is only specialized for single core contact smart card, brief function means that high working efficiency.

Features:

1. Integration of cavities milling, vacuum cleaning, cavity detection, glue tape punching, lamination, module tape punching, module embedding and ATR testing.

2. Specialized fixture design for card centering system, protecting the milling depth from the influences of the card thickness and dimension.

3. Milling program can be designed by operator, cavity layer can be set 3 layers, each program can be save individually.

4. Z-Axis moving is realized through guide and ball screw driven by high precision servo motor, to provide the accurate milling depth. Special tool changing program make tool changing is fast and convenient.

5. Depth detection device, double card detection device, card direction detection device and card correction functions.

6. Cards transferred through belt driven by servo motor ensure the safety and stability of the machine.

7. Film loading is controlled by serve motor with sensor detection. Faulty module can be distinguished automatically.

8. IC tape feeding and collecting automatically.

9. Bad chips rejected automatically.

10. Special pick up module structure which ensure module without damage.

11. Module punching tool positioning by dowel pin.

12. Strip IC stepping is controlled by servo motor, feeding distance can be adjusted by parameter, and module has double protection with photoelectric sensor monitoring.

13. Servo motor working with high precision guider and lead screw makes module transfer more stable and reliable. Module transfer position can be changed easily.

14. Special design for hot press station makes sure module sticking to plastic card tightly. It is convenient to change the hot pressers.

15. ATR test system ensures qualified rate of embedding.

16. Machine no embedding without chip on the card.

17. Hot welding head have X & Y direction fine adjustment function.

Technical parameter:

| Dimension: |

L 2000*W 1000*H 1520 mm |

| Weight: | 1500 kg |

| Power supply: | AC 380V 50/60Hz |

| Power: | 8 kw |

|

Air pressure: |

6 kg/cm2 |

|

Air consumption: |

800 L/min |

|

Control method: |

PC |

Company Profile:

Shenzhen Yuanmingjie Technology Co., Ltd was founded in 2010 for research and development of intelligent manufacturing equipment. With many years innovations and development, Yuanmingjie has become the High Technology Corporation who has got high reputation in China and overseas. Yuanmingjie is the Shenzhen innovative enterprise and the member of Shenzhen software industry association, we also got Guangdong province credible enterprise identification.

Yuanmingjie integrated R&D, manufacturing and sales, who concentrates on supplying better equipment and supporting facilities solution for smart card factories. Our main products include production line for contact smart card, contactless smart card, dual interface smart card, RFID electrical labeling and personalized equipment.

Elites are valued by Yuanmingjie technology, lots of professionals with more than 10 years experience in equipment development gather here. With so many years of technical innovation and experience, Yuanmingjie breakthrough the traditional dependence of domestic enterprises on foreign techniques, reaches a leading position in China, who firstly adopts advanced Ultrasonic Embedding technique and Precision Vibrator Bowl. Meanwhile dual interface smart card equipment and milling and embedding two in one equipment have got National Invention Patent and CE certificate.

Spirit of Yuanmingjie: To develop by guide of market, to gain customers by credibility, to gain reputation by better quality.

Mission of Yuanmingjie: To create value for customers and society constantly.

Vision of Yuanmingjie: With continual technical innovation, wisdom and efforts from members of yuanmingjie, we will fulfill customers current need and create high needs, to be the top automatic equipment and technical solutions supplier.

Related Keywords