Smart Card Six Cores Chip Embedding Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 35 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO, CE |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN |

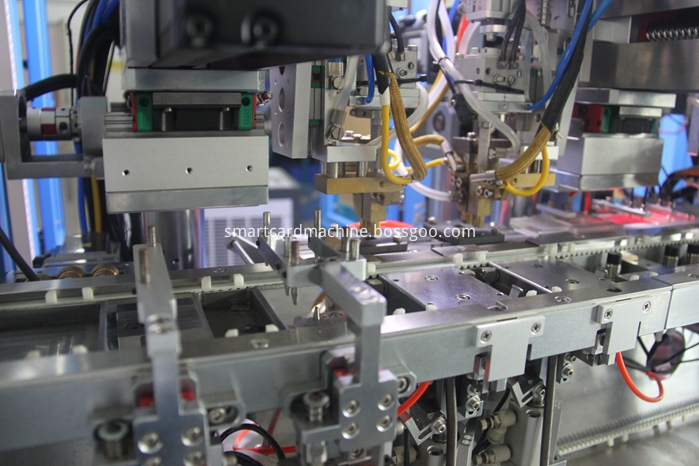

Smart Card Six Cores Chip Embedding Machine adopts four smart card feeding magazines, four chip transporting heads and twenty-four chip welding heads. Four smart card feeding magazines can be switched automatically after one magazine is empty.

Chip transporting devices are controlled by servo system, each one of them is in charge of one side of six cores smart card.

There are sensors to detect the chip before chip welding process, it will not weld the card without chip. Every chip will be welded by three hot welding heads and one cold presser.

Feature:

1. Integration of module test, lamination, module punching, embedding and testing.

2. Film loading is controlled by serve motor with sensor detection. Faulty module can be distinguished automatically.

3. Special design and several heating heads make a better lamination.

4. Servo motor working with high precision guide rail and lead screw. Change parameters directly to change module transfer position.

5. Special design for hot pressing makes sure module sticking to plastic card tightly. It`s easy to change hot pressing heads. Groups of hot pressing heads ensure good embedding quality.

6. Servo motor drives belt to transfer card, ensure the safety and stability of the machine.

7. Milling cavity detection, double-card detection and card position correction.

8. Detect module presence or not before hot press. Don`t hot press when module no presence.

9. Cold press after hot press.

10. Hot pressing heads with X,Y direction trimming function. Needn`t adjust home position of hot pressing heads when changing them.

11. Glue lamination adopts special flat structure and various heating heads, which overcomes the difficulty of glue lamination. This unique structure ensures there is no need to take fine turning while changing welding head.

Company Profile:

Shenzhen Yuanmingjie Technology Co., Ltd was founded in 2010 for research and development of intelligent manufacturing equipment. With many years innovations and development, Yuanmingjie has become the High Technology Corporation who has got high reputation in China and overseas. Yuanmingjie is the Shenzhen innovative enterprise and the member of Shenzhen software industry association, we also got Guangdong province credible enterprise identification.

Yuanmingjie integrated R&D, manufacturing and sales, who concentrates on supplying better equipment and supporting facilities solution for smart card factories. Our main products include production line for contact smart card, contactless smart card, dual interface smart card, RFID electrical labeling and personalized equipment.

Elites are valued by Yuanmingjie technology, lots of professionals with more than 10 years experience in equipment development gather here. With so many years of technical innovation and experience, Yuanmingjie breakthrough the traditional dependence of domestic enterprises on foreign techniques, reaches a leading position in China, who firstly adopts advanced Ultrasonic Embedding technique and Precision Vibrator Bowl. Meanwhile dual interface smart card equipment and milling and embedding two in one equipment have got National Invention Patent and CE certificate.

Spirit of Yuanmingjie: To develop by guide of market, to gain customers by credibility, to gain reputation by better quality.

Mission of Yuanmingjie: To create value for customers and society constantly.

Vision of Yuanmingjie: With continual technical innovation, wisdom and efforts from members of yuanmingjie, we will fulfill customers current need and create high needs, to be the top automatic equipment and technical solutions supplier.

Related Keywords