No Carrier Black Masterbatch-65% Carbon Black

-

USD2300≥40 Bag/Bags

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 40 Bag/Bags

- Min. Order:

- 40 Bag/Bags

- Delivery Time:

- 10 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 150kg/Hour |

| Supply Ability: | 100Ton Per Month |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | SGS |

| Transportation: | Ocean |

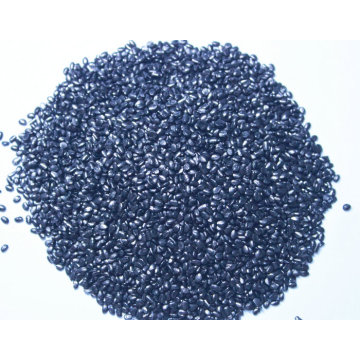

Description---No Carrier Black Masterbatch--W3306

No Carrier Black Masterbatch W3306 is made with the China-Made common ZY-1 carbon black and high molecular weight additives, with production procedures of mixing, milling, refining, extuding, graluating and polishing. No Carrier Black Masterbatch W3306 contents 65% Carbon Black, does not have any polymer Carrier. It has reddish shade color and competitive price than the No Carrier Black Materbatch W3308 and W3306, , the same using for all kinds of enginerring materils compounding, but more econoical, either not suitable for the directly produciton for end-products, such as blowing film, injection, extrusion so on. No Carrier Black Masterbatch W3306 will not affect the physical performance of the compounding engineering material, it could perfectly ensure the end-products mechanical performance.

Appearance: 2.0*2.5mm unregular black pellet

Application: No Carrier Black Masterbatch is suitable for the engineering material compounding, such as ABS, PC, PA66, PS, POM, PP, Nylon so on.

Property: Environment-friendly, nontoxic, smellless, glory appreacnce and high concentration and bluish shade, good disperssion, no pollution. Complied with ROHS requirements and heavy metal regulations.

Characteristic: No Carrier Black Masterbatch is one new product, it overcomes the shortcomings of common black masterbatches, such as anti high production temperature (as high as 400 ℃), high concentration, no affection to the plastic performance of the modified material, no moisture included,lower dosage.

Usage: Mixed with materials.

Dosage: suggested 0.5-1%.

Technical Index:

Density:25℃ 1,048kg/m3

Melting Point:130-480℃

Heat Resistant:380-400℃

Melting Speed: not applicable

Water:<0.05%

Package:25kgper bag, KP bag or PE white bag.

Storage: Place in dry and cool warehose, avoid sun shine and raining.

Related Keywords