All Truck and Bus Wheel Alignment

- Payment Type:

- T/T, Western Union

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Air, DHL

- Port:

- Yantian, Shenzhen, Hong Kong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300sets/ month |

| Supply Ability: | 300sets/ month |

| Payment Type: | T/T,Western Union |

| Certificate: | FCC, CE, RoHS |

| Transportation: | Ocean,Air,DHL |

| Port: | Yantian,Shenzhen,Hong Kong |

Truck Wheel Alignment

All truck and bus wheel alignment is the most advanced truck wheel alignment at present. This is 5D truck alignment with total 5 cameras. It is portable and easy to use. Once charge is for 8 hours usage. We offer 3 years warranty for 5D truck wheel alignment aftersales service.

Advantages of All Truck and Bus Wheel Alignment:

3D technology overcomes all disadvantages of 2D technology, such as mismeasurement.low precision.human factors , which are caused by following reasons:

[1]Original errors caused by wheel rim deformation cannot be eliminated by compensation;

[2]Errors caused by wheel clamp deformation can not be eliminated;

[3]Precision of truck should be higher than that of cars, but 2D technology makes it lower;

[4]Different measurement results caused by different operational approaches and strength.

3D technology adopts anti-shake measurement technology. It can eliminate time errors caused by car body shake within 20 seconds, improving labor efficiency. Meanwhile, it avoids problems caused by wireless and high-frequency interference. It can be used at any indoor places.

Configuration list of All Truck and Bus Wheel Alignment

|

model |

Sensor (1 ) |

Targets (8) |

Wheel clamp (8) |

Turntable (4) |

Frame offset tool(1) |

Tablet PC(1) |

Wedge block(2) |

Cabinet(1) |

24inch wireless TV (1) |

|||

|

SY808 |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

|

|

|||

|

SY808A |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

|||

Measurement Range and Accuracy of All Truck and Bus Wheel Alignment:

References

Accuracy

Measurement Range

Measurement TotalRange

Camber

±0.02°

±8°

±8°

Caster

±0.05°

±19°

±19°

K.P.I

±0.02°

±19°

±19°

Toe

±0.02°

±22.5°

±45°

Turning Angle

±0.08°

±22.5°

±45°

Track

width difference

±0.03°

±2°

±8°

Front Setback

±0.02°

±2°

±4°

Maximum Turning Angle

±0.02°

±45°

±45°

Comparison between CCD and All Truck and Bus Wheel Alignment

CCD:

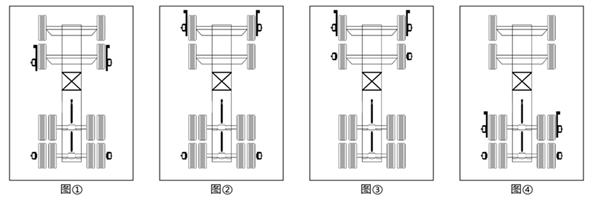

Step 1 Picture ① shows that reference is No.4 axle, adjust the toe of No.2 axle;

Step 2 Picture ② shows that reference is No.4 axle, adjust the toe of No.1 axle;

Step 3 Picture ③ shows that the drag link between No.1 and 2 axle makes No.1 and 2 axle parallel;

Step 4 Picture ④ shows that the adjustment of No.3 axle individual toe.

Remarks::When installing sensors, wheels need to be lifted to make run-out compensation.

5D:

Step 1 Install 8 targets and wheel clamps;

Step 2 Lay two sensors on the ground just like the picture shows;

Step 3 Drive the truck forward and turn the wheel to 8 degree to finish run-out compensation;

Step 4 Get the measurement results and monitor its dynamic

Our Team

Related Keywords