Heavy Duty Wheel Alignment for Tyre Repair

- Payment Type:

- T/T, Western Union

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Air, DHL

- Port:

- Shenzhen, Hongkong, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300sets/ month |

| Supply Ability: | 300sets/ month |

| Payment Type: | T/T,Western Union |

| Certificate: | FCC, CE, RoHS |

| Transportation: | Ocean,Air,DHL |

| Port: | Shenzhen,Hongkong,Yantian |

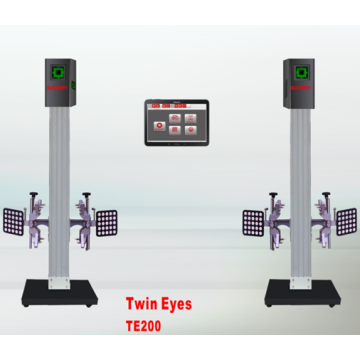

This is heavy duty wheel alignment for tyre repair. Heavy duty wheel alignment for tyre repair is easy to operate and the price is competitive. China Heavy Duty Wheel Alignment can finish car tyre diagnosis at the same time. Besides, this is the first one in China to use 5D technology which is more efficient and precise than CCD technology.

Advantages of Heavy Duty Wheel Alignment for Tyre Repair:

3D technology overcomes all disadvantages of 2D technology, such as mismeasurement.low precision.human factors , which are caused by following reasons:

[1]Original errors caused by wheel rim deformation cannot be eliminated by compensation;

[2]Errors caused by wheel clamp deformation can not be eliminated;

[3]Precision of truck should be higher than that of cars, but 2D technology makes it lower;

[4]Different measurement results caused by different operational approaches and strength.

3D technology adopts anti-shake measurement technology. 3D Truck Wheel Alignment can eliminate time errors caused by car body shake within 20 seconds, improving labor efficiency. Meanwhile, Heavy Duty 3D Wheel Alignment avoids problems caused by wireless and high-frequency interference. It can be used at any indoor places.

Configuration list of Heavy Duty Wheel Alignment for Tyre Repair

|

model |

Sensor (1 ) |

Targets (8) |

Wheel clamp (8) |

Turntable (4) |

Frame offset tool(1) |

Tablet PC(1) |

Wedge block(2) |

Cabinet(1) |

24inch wireless TV (1) |

|||

|

SY808 |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

|

|

|||

|

SY808A |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

|||

Measurement Range and Accuracy of Heavy Duty Wheel Alignment for Tyre Repair:

References

Accuracy

Measurement Range

Measurement TotalRange

Camber

±0.02°

±8°

±8°

Caster

±0.05°

±19°

±19°

K.P.I

±0.02°

±19°

±19°

Toe

±0.02°

±22.5°

±45°

Turning Angle

±0.08°

±22.5°

±45°

Track

width difference

±0.03°

±2°

±8°

Front Setback

±0.02°

±2°

±4°

Maximum Turning Angle

±0.02°

±45°

±45°

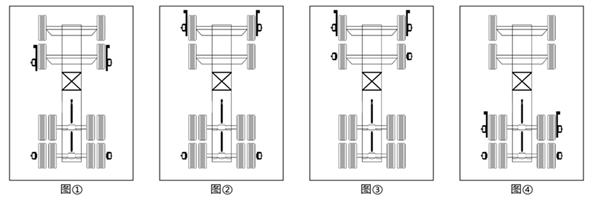

Comparison between CCD and 5D Wheel Alignment for Truck

CCD:

Step 1 Picture ① shows that reference is No.4 axle, adjust the toe of No.2 axle;

Step 2 Picture ② shows that reference is No.4 axle, adjust the toe of No.1 axle;

Step 3 Picture ③ shows that the drag link between No.1 and 2 axle makes No.1 and 2 axle parallel;

Step 4 Picture ④ shows that the adjustment of No.3 axle individual toe.

Remarks::When installing sensors, wheels need to be lifted to make run-out compensation.

3D:

Step 1 Install 8 targets and wheel clamps;

Step 2 Lay two sensors on the ground just like the picture shows;

Step 3 Drive the truck forward and turn the wheel to 8 degree to finish run-out compensation;

Step 4 Get the measurement results and monitor its dynamic

case

Our Team

Related Keywords