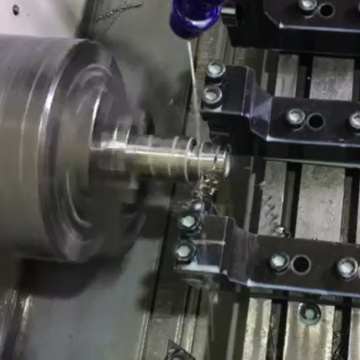

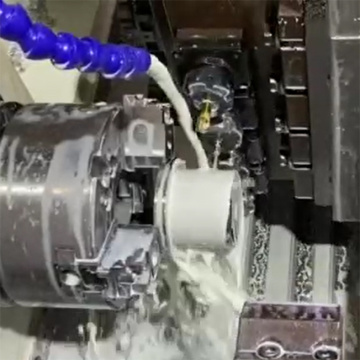

High Speed Lathe Machining Stainless Steel Accessories

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

High Speed Lathe Machining Stainless Steel Accessories

Stainless steel accessories parts are usually used to fasten expensive machine parts because of stainless steel accessories parts are beauty, durability and strong corrosion resistance. In the mass lathe machining stainless steel parts, through many tests and reasonable selection of turning elements, the coating cutter is better, and the machining efficiency is more than five times higher than that of the conventional lathe. In lathe machining stainless steel parts, the coating of coated tools can prevent chips from contacting with tools directly, reduce friction and mechanical thermal stress. When lathe machining stainless steel, coating cutter can shorten cutting time, reduce cost, reduce tool changing times, improve machining accuracy, and prolong tool life. Coated tools reduce or eliminate the use of cutting fluid.

The variety of our precision machining centers allows us to offer our customers the best prices for CNC machining stainless steel components. Regardless of the size or specification of your order, we have the equipment that can to do the job right and produce your parts when and how you need them.

Fast delivery is our advantage. When CNC turning machining parts, we just need 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, and the fastest sample to complete just need one day. Our factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

As a custom CNC machining shop, we machine specialty parts out of any specified material, from standard to exotic.

|

Aluminum |

6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

|

Copper |

Copper, Brass, Bronze |

|

Stainless Steel |

SUS303, SUS304,( 57483255, 57475738, 57450747, 57445320, 57376477, 57351300, 57319298, 57302244, 57231796, 57218926, 56677102, 54142921,1.4301), SUS316 |

|

Steel |

Q235, 45 #, A3, 718H, S136, SKD11 |

|

Titanium |

|

|

Plastic |

Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI etc.. |

In addition, we also offer products for your secondary machining services: Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nickel (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts, Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing.

Related Keywords