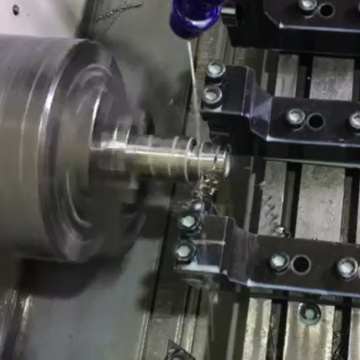

Custom Machining Stainless Steel Industrial Parts On Lathe

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Custom Machining Stainless Steel Industrial Parts On Lathe

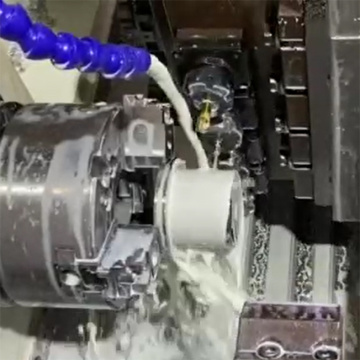

Machining stainless steel on lathe is a process in which stainless steel is machined by lathe according to drawings. The machinability of stainless steel industrial parts is much worse than that of medium carbon steel. If the machinability of common 45 steel is 100%, the relative machinability of stainless steel industrial parts can only reach 40%. Machining stainless steel on lathe mainly shows the characteristics of severe work hardening, large cutting force, high cutting temperature, chip not easy to break, easy to bond, tool wear and tear. We have a professional team of CNC machining technology, accumulated a lot of experience in machining stainless steel on lathe .Our technical team will review each drawing and arrange each machining step, set the parameters of the CNC machining center. We also have set up a special sample production team to provide small quantities of machining services.

The variety of our precision machining centers allows us to offer our customers the best prices for CNC machining stainless steel components. Regardless of the size or specification of your order, we have the equipment that can to do the job right and produce your parts when and how you need them.

Fast delivery is our advantage. When CNC turning machining parts, we just need 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, and the fastest sample to complete just need one day. Our factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

As a custom CNC machining shop, we machine specialty parts out of any specified material, from standard to exotic.

|

Aluminum |

6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

|

Copper |

Copper, Brass, Bronze |

|

Stainless Steel |

SUS303, SUS304,( 57302244, 57231796, 57218926, 56677102, 54142921,1.4301), SUS316 |

|

Steel |

Q235, 45 #, A3, 718H, S136, SKD11 |

|

Titanium |

|

|

Plastic |

Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI etc.. |

In addition, we also offer products for your secondary machining services: Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nickel (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts, Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing.

Related Keywords