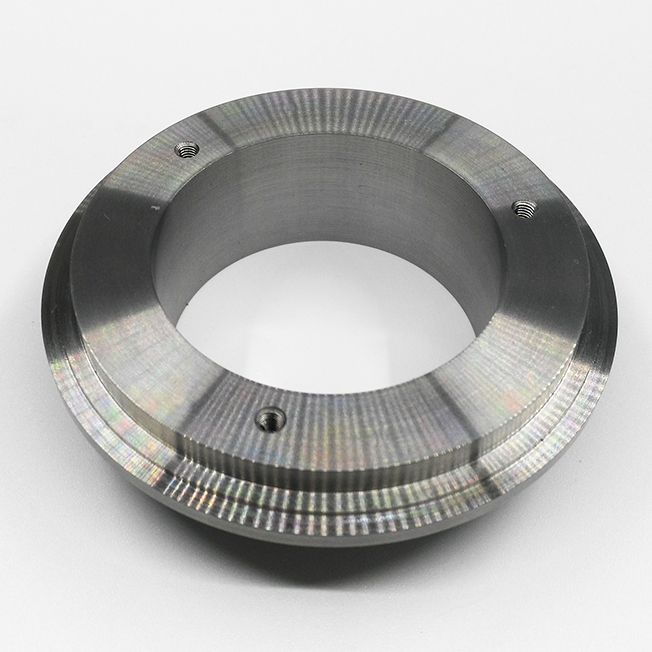

Turning stainless steel on lathe

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 1300/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

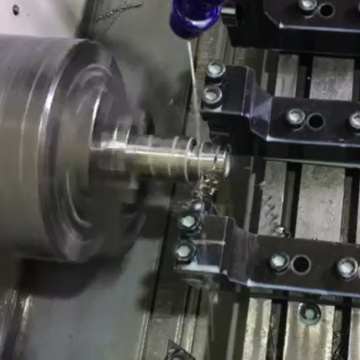

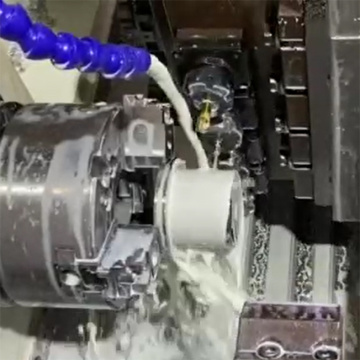

Turning stainless steel on lathe processing of the object is relatively large workpiece.Usually divided into roughing turning and finishing turning,Rough turning selection of low-speed, large cnc turning capacity.Reduce the number of tool and workpiece contact, while avoiding the tip and rough skin contact, reduce tool wear.finishing turning stainless steel High-speed turning is performed at one time.

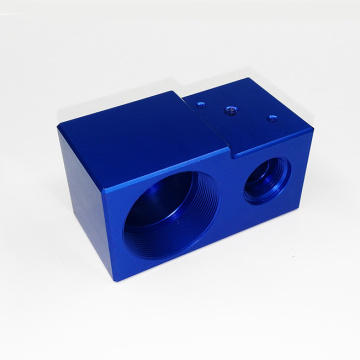

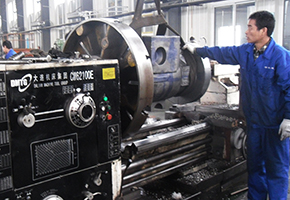

Our CNC Lathes (turning) has three configurations: Single Turret Single Spindle, Twin Turret Twin Spindle.As well as automatic feeding function.Using Esprit software CAM programming,The following cutting action can be performed:The following cutting action can be performed. There are six lathe. Machining tuinring size of the largest diameter can reach ф860mm. The cnc turnining and cnc milling machining materials are:Aluminum 6061,6063,6061-T6,7075,5052.2017.6082. Alloy Steels,Carbon Steel,Brass,Bronze ,Stainless steel: 303,304, 316. Plastic:Delrin, Neoflon®,Nylon,Phenolic Resin,PTFE. ,PC,ABS.Secondary Services Offered:laser engraving LOGO.Anodizing,Plating Chrome,Nickel,RoHS Zin,Etc.Assembly Welding,Heat Treating,Powder Coating,Centerless Grinding.

Each piece of the CNC machining turning parts is rigorously tested three times,First Article Inspection, Process inspection,Final inspection.The inspection work and CNC turning process control in close connection.The quality of each process or the possible quality problems left off.Reject the unqualified product, so that it can not be put into the sequence or factory, so as to achieve the purpose of process control.

Each piece of the CNC machining turning parts is rigorously tested three times,First Article Inspection,Process inspection.Final inspection.The inspection work and CNC turning process control in close connection.The quality of each process or the possible quality problems left off.Reject the unqualified product, so that it can not be put into the sequence or factory, so as to achieve the purpose of process control.

Related Keywords