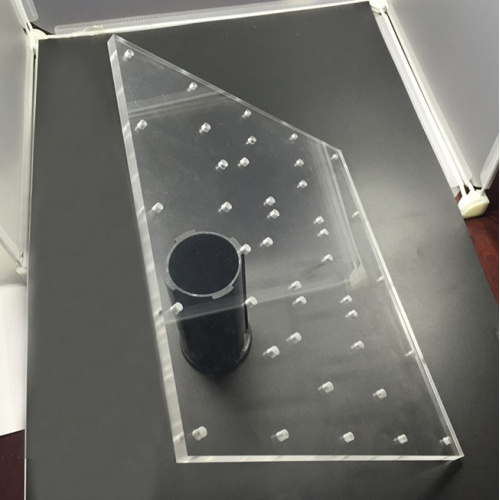

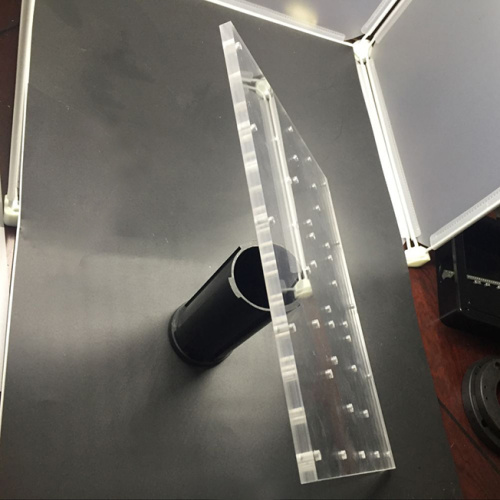

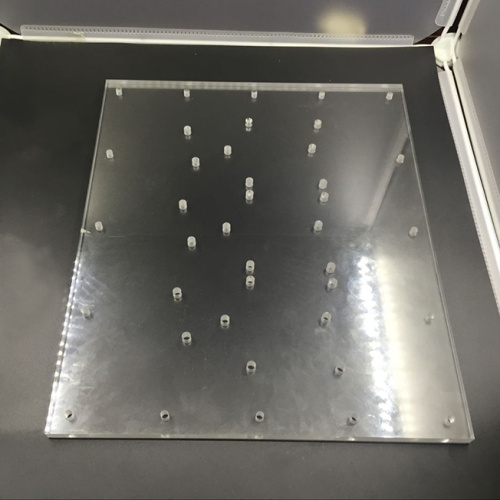

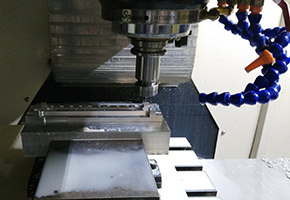

CNC Milling Machining Acrylic Pusher Sheet

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

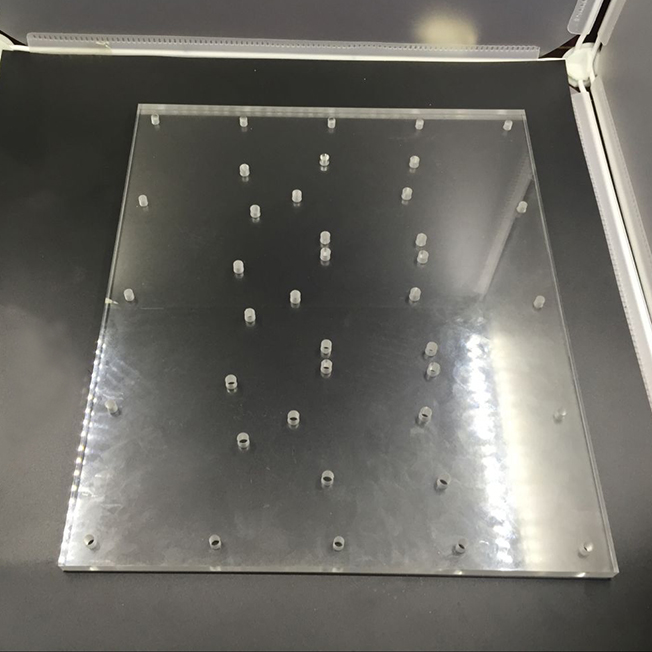

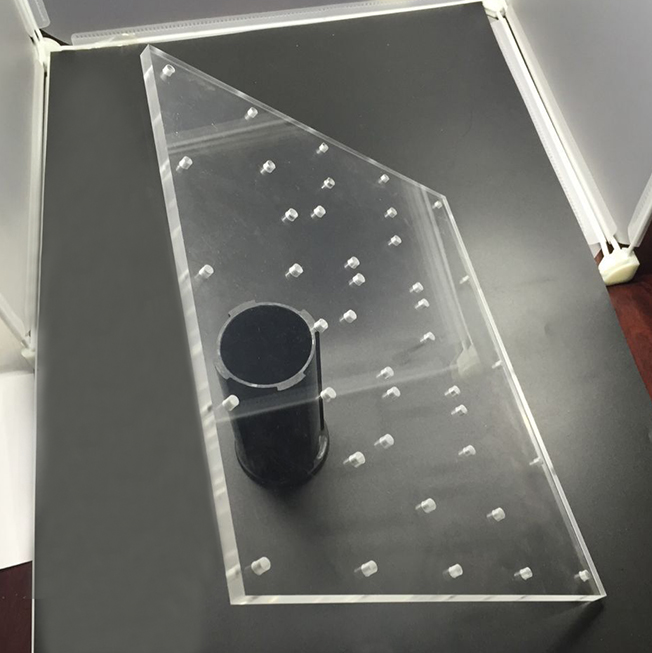

CNC Milling Machining Acrylic Pusher Sheet

Acrylic sheet is crystal transparent color, so acrylic has "plastic crystal" reputation. Milling acrylic pusher sheet has excellent weather resistance. It won't turn yellow even after using for a long time, and has good surface hardness and gloss. Milling acrylic pusher sheet is of great plasticity and can be made into all kinds of shapes. In the milling acrylic pusher sheet, the protective film on the board should be retained until the final step is finished so as to prevent the surface from scratching. If can't do this, then when milling acrylic pusher sheet should put the sheet on clean and soft material.

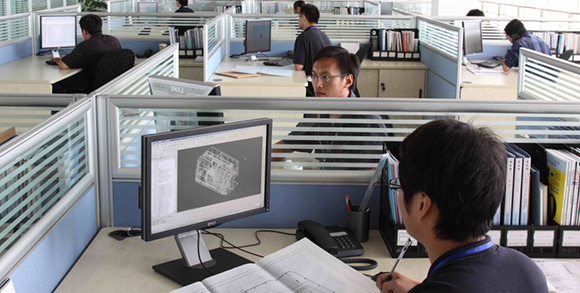

We have a dedicated CNC machining technology team. Factory processes: order review, drawing review, product CNC programming, production planning, machining, quality inspection, packaging and transportation. Our technical staff has accumulated a lot of technical experience in the plastic machining processing, we have a detailed analysis of the product deformation in machining plastic. In almost all the plastic machining process, the worker will make a fixture to control the deformation of the product.

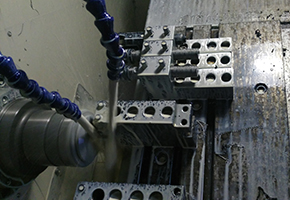

1 Our Factory Equipment Capabilities

- CNC Machinig Center, 3 Axis, 4 Axis.

- CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret.

- Milling Machine

- Grinding Machine

-

Drill Press

-

Tapping Center

-

Rotary Indexer

- Punch

2 Material ( Machining Metal )

-

Titanium

- Aluminum 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017.

- Copper, Brass, Bronze, Phosphor Bronze. ( C10100, C10200, C11000, C12200, C26000, C27000, C28000, C33000, C220, C510, C630 )

- Stainless Steel 303, 304, 316 ( 1.4305, 1.4301 )

- Steel Ordinary carbon structural Steel, Quality carbon structural steel, cast steel, Iron. (Q195, Q215, Q235, Q255, 10#, 20#, 35#, 45#, 718H, S136, SKD11 )

Machining Plastic :

Delrin (Black, White, Blue, Red, Yellow), Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, Acrylic, PMMA, PC, Polycarbonate, PAI, PPS, PA, PVDF, POM, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM.

3 Machining Processes

- CNC Milling and CNC Turning

- CNC Milling

- CAM Programming

- sheet metal fabrication

- Grinding

- Cutting

- Thread Turning / Milling threading

- Tapping

- Drilling

- Knurling

4 Part Size ( CNC Milling and CNC Turning )

- CNC Milling Parts ( Max ) : Length 1030mm, Width 800mm, Height 750mm.

- CNC Turning Parts (Max ): Diamter 680mm, Length 750mm. The size of the above parts are machined in the workshop.

5 Tolerance: 0.01mm. Minority size: 0.005mm. The measuring instrument can measure the dimension precision: 0.01mm.

6 Secondary Services of Machining Parts

-

Assemble

-

Plating Zinc Color ( Machining Steel parts )

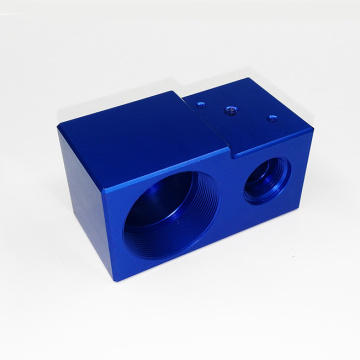

- Anodize, Anodize color ( Black, Clear, Red, Blue,Yellow, Etc. ), Hard Anodize, Hard Anodize Teflon. ( Machining Aluminum )

- Electroless Nickel ( Machining Aluminum parts, Machining Stainless Steel parts, Machining brass parts )

- Passivation ( Machining Stainless Steel parts )

- Sand Blasting ( Machining Aluminum parts )

- Brushed ( Machining Aluminum parts , Machining Stainless Steel parts )

- Bluing and Blackening ( Machining Steel parts )

- Trivalent Chromium Process ( Machining Aluminum parts )

- Welding,brazing and soldering.

- Centerless Grinding and Burnishing

Related Keywords