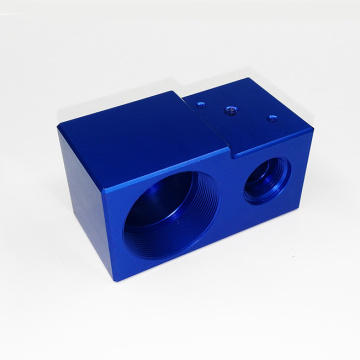

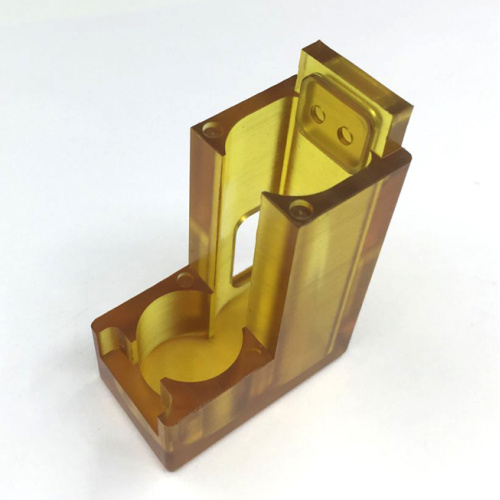

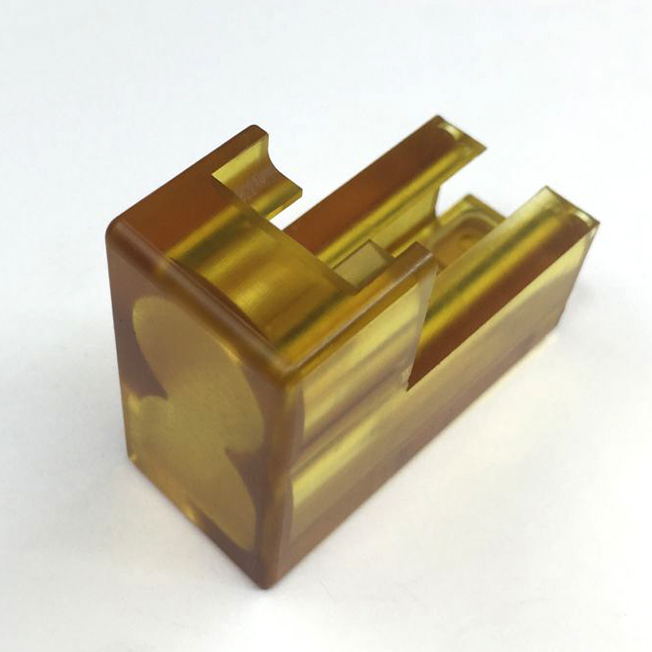

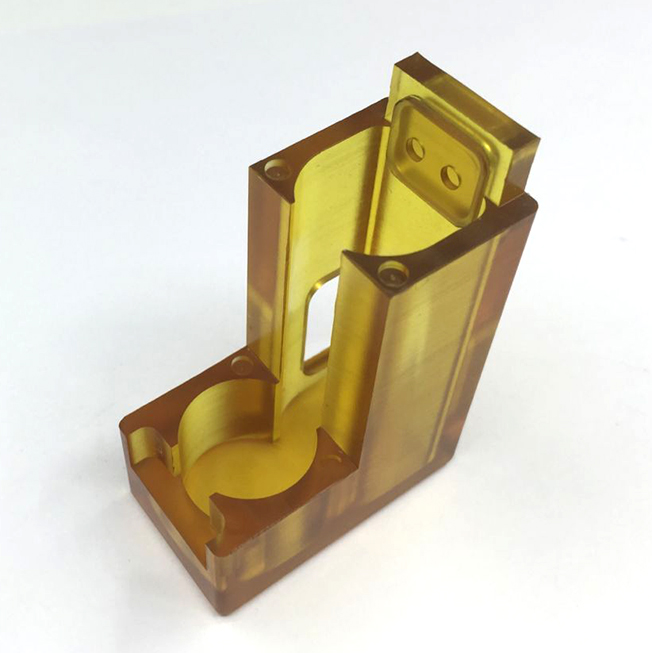

Quality Ultem Plastic Parts Machining

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Quality Ultem Plastic Parts Machining

Ultem is amorphous PEI. Ultem machined parts has the highest resistance to high temperature and dimensional stability, as well as chemical, flame retardant, electrical, high strength, high stiffness and so on. Ultem machined parts is widely used in electronic, electrical, medical, lighting, food processing, transportation and other industries. The stability of Ultem machined parts is excellent. One outstanding feature is that it can withstand long time high temperature test, and it is difficult to deform in high temperature environment. Ultem machined parts not only has the incomparable high strength characteristics, it also has outstanding ductility. Ultem machined parts's yield stretching allows it to mix freely with various designs.

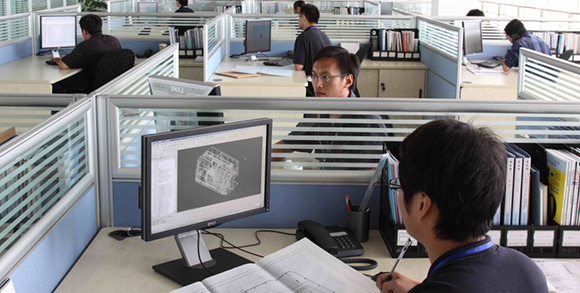

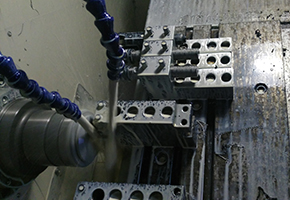

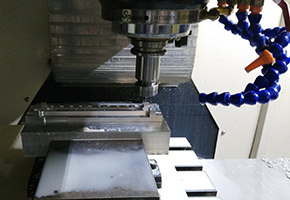

1 Our Factory Equipment Capabilities

- CNC Machinig Center, 3 Axis, 4 Axis.

- CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret.

- Milling Machine

- Grinding Machine

-

Drill Press

-

Tapping Center

-

Rotary Indexer

- Punch

2 Material ( Machining Metal )

-

Titanium

- Aluminum 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017.

- Copper, Brass, Bronze, Phosphor Bronze. ( C10100, C10200, C11000, C12200, C26000, C27000, C28000, C33000, C220, C510, C630 )

- Stainless Steel 303, 304, 316 ( 1.4305, 1.4301 )

- Steel Ordinary carbon structural Steel, Quality carbon structural steel, cast steel, Iron. (Q195, Q215, Q235, Q255, 10#, 20#, 35#, 45#, 718H, S136, SKD11 )

Machining Plastic :

Delrin (Black, White, Blue, Red, Yellow), Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, Acrylic, PMMA, PC, Polycarbonate, PAI, PPS, PA, PVDF, POM, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM.

3 Machining Processes

- CNC Milling and CNC Turning

- CNC Milling

- CAM Programming

- sheet metal fabrication

- Grinding

- Cutting

- Thread Turning / Milling threading

- Tapping

- Drilling

- Knurling

4 Part Size ( CNC Milling and CNC Turning )

- CNC Milling Parts ( Max ) : Length 1030mm, Width 800mm, Height 750mm.

- CNC Turning Parts (Max ): Diamter 680mm, Length 750mm. The size of the above parts are machined in the workshop.

5 Tolerance: 0.01mm. Minority size: 0.005mm. The measuring instrument can measure the dimension precision: 0.01mm.

6 Secondary Services of Machining Parts

-

Assemble

-

Plating Zinc Color ( Machining Steel parts )

- Anodize, Anodize color ( Black, Clear, Red, Blue,Yellow, Etc. ), Hard Anodize, Hard Anodize Teflon. ( Machining Aluminum )

- Electroless Nickel ( Machining Aluminum parts, Machining Stainless Steel parts, Machining brass parts )

- Passivation ( Machining Stainless Steel parts )

- Sand Blasting ( Machining Aluminum parts )

- Brushed ( Machining Aluminum parts , Machining Stainless Steel parts )

- Bluing and Blackening ( Machining Steel parts )

- Trivalent Chromium Process ( Machining Aluminum parts )

- Welding,brazing and soldering.

- Centerless Grinding and Burnishing

Related Keywords