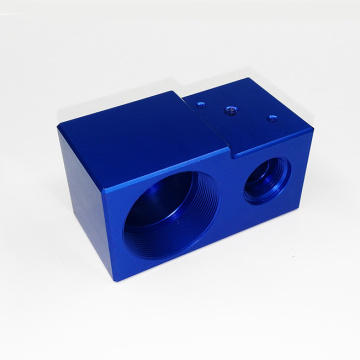

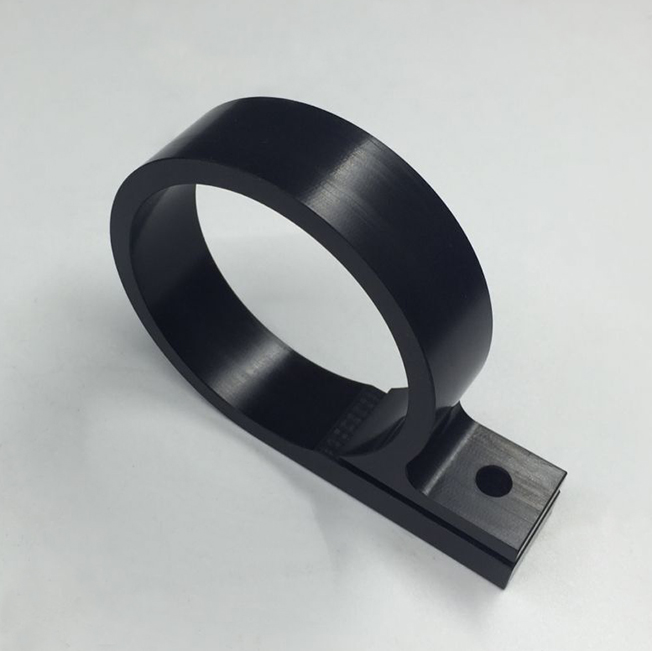

Custom Machining Engineering Plastic Components

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

In recent years, engineering plastic components consumption increased every year. It is expected that the demand for engineering plastic parts will continue to grow in the next few years. Engineering plastic components refers to the plastic parts which has higher properties in strength, modulus and toughness, and higher use temperature, longer service life, and can replace the use of metal as structural materials. Engineering plastic components has mechanical properties such as high strength, high mechanical modulus, low creep, strong wear resistance and fatigue resistance. Engineering plastic components is mainly used in electronic, electrical, mechanical, automotive, building materials, light industry and other fields.

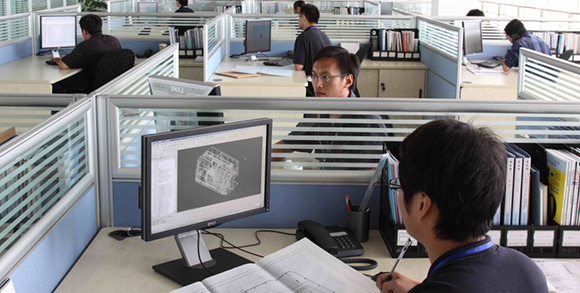

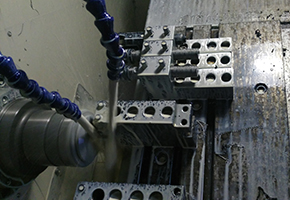

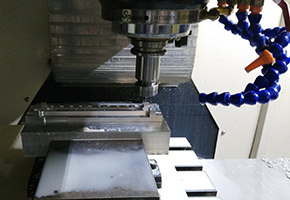

1 Our Factory Equipment Capabilities

- CNC Machinig Center, 3 Axis, 4 Axis.

- CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret.

- Milling Machine

- Grinding Machine

-

Drill Press

-

Tapping Center

-

Rotary Indexer

- Punch

2 Machining Processes

- CNC MillingCNC Turning

- CNC Milling

- CAM Programming

- sheet metal fabrication

- Grinding

- Cutting

- Thread Turning / Milling threading

- Tapping

- Drilling

-

Knurling

3 Material ( Machining Metal )

-

Titanium

- Aluminum 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017.

- Copper, Brass, Bronze, Phosphor Bronze. ( C10100, C10200, C11000, C12200, C26000, C27000, C28000, C33000, C220, C510, C630 )

- Stainless Steel 303, 304, 316 ( 1.4305, 1.4301 )

- Steel Ordinary carbon structural Steel, Quality carbon structural steel, cast steel, Iron.(Q195, Q215, Q235, Q255, 10#, 20#, 35#, 45#, 718H, S136, SKD11 )

Machining Plastic :

Delrin (Black, White, Blue, Red, Yellow), Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, Acrylic, PMMA, PC, Polycarbonate, PAI, PPS, PA, PVDF, POM, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM.

4 Part Size ( CNC Milling and CNC Turning )

- CNC Milling Parts ( Max ) : Length 1030mm, Width 800mm, Height 750mm.

- CNC Turning Parts (Max ): Diamter 680mm, Length 750mm. The size of the above parts are machined in the workshop.

5 Tolerance:0.01mm. Minority size: 0.005mm. The measuring instrument can measure the dimension precision: 0.01mm.

6 Secondary Services of Machining Parts

-

Assemble

-

Plating Zinc Color ( Machining Steel parts )

- Anodize, Anodize color ( Black, Clear, Red, Blue,Yellow, Etc. ), Hard Anodize, Hard Anodize Teflon. ( Machining Aluminum )

- Electroless Nickel ( Machining Aluminum parts, Machining Stainless Steel parts, Machining brass parts )

- Passivation ( Machining Stainless Steel parts )

- Sand Blasting ( Machining Aluminum parts )

- Brushed ( Machining Aluminum parts , Machining Stainless Steel parts )

- Bluing and Blackening ( Machining Steel parts )

- Trivalent Chromium Process ( Machining Aluminum parts )

- Welding,brazing and soldering.

- Centerless Grinding and Burnishing

Related Keywords