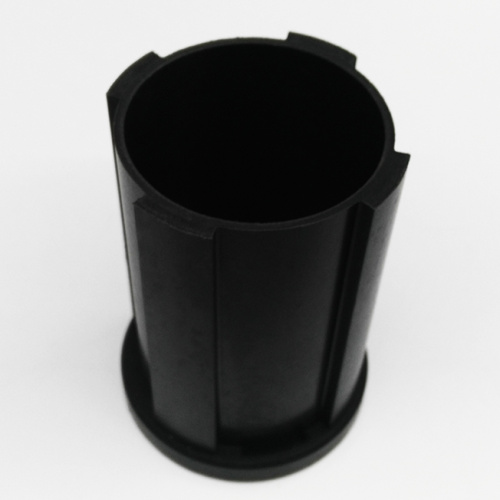

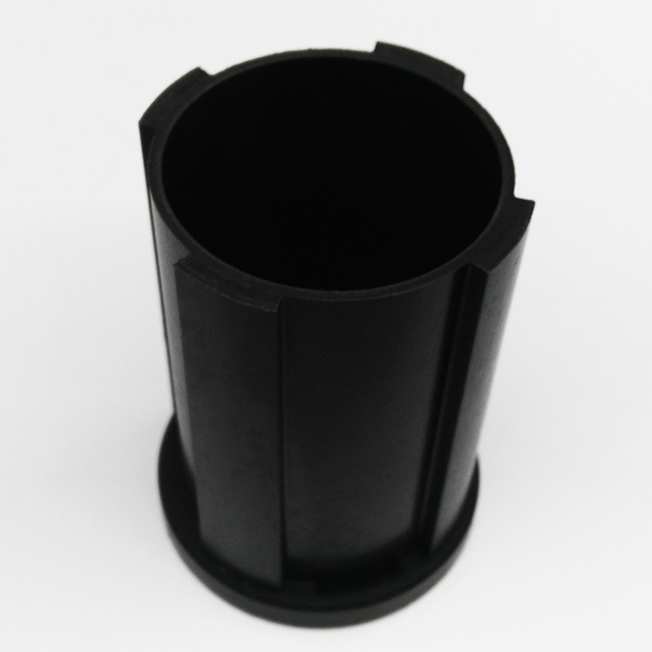

nylon machining CNC parts

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 13000/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

Nylon machining parts high mechanical strength, good toughness, a higher tensile and compressive strength.Friction coefficient is small, high wear resistance.Nylon density is small, in industrial applications, can replace copper.machining nylon parts are bearings, gears, pump leaves and other parts.

Our plastic machining includes:delrin, neoflon, teflon, ultem, peek, PC ,PMMA, PTFE, PEI,, POM, ABS.

CNC machining including cnc milling and cnc turning, cunting, grinding, milling, sheet metal fabrication.cnc milling machining and cnc turnining materials are: Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.Steel: Q215,Q235,45 #, 15#,A3, 718H, S136, SKD11, Stainless steel: SUS303, SUS304, (1.4301), SUS316. copper / bronze. Product surface treatment: anode (clear,black, blue, yellow, can also customize a variety of colors).Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

As a custom CNC machining shop, we machine specialty parts out of any specified material, from standard to exotic. Some of the standard materials from which we CNC Milling machining include aluminum, copper, brass, and steel, as well as plasti.Our knowledge and experience in processing a wide variety of materials makes it the ideal choice for the you required part.

From the procurement of raw materials to CNC machining parts shipments, we have established a complete set of quality control system. Our inspection tools are:Digital caliper,Micrometer Calipers , height gauge ,Profile projector...Tolerances can be measured +/-0.01mm and 0.001mm.

The whole process of operating workers by SOP operations, IPQC products for each processing steps to detect,Make sure the product meets the requirements before proceeding to the next CNC machining Turning.And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report.

We focus on short-term delivery, commitment to provide samples a week. For a simple CNC Machining parts, complete the sample in 3 days. The factory provides 2 ~ 3 sets of CNC Machining Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day. In order to meet these services, we also have a qualified supplier base, So that we can provide products from the surface to the parts LOGO mark the integrity of the quality of cnc turning services.

Related Keywords