Best plastic for machining

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 13000/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

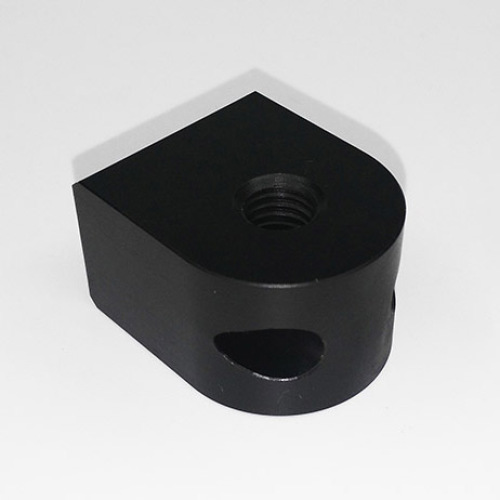

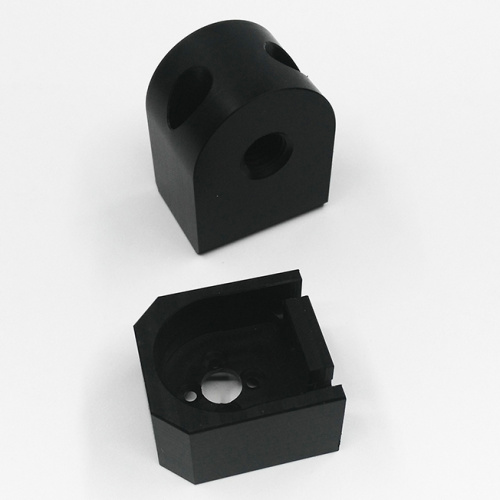

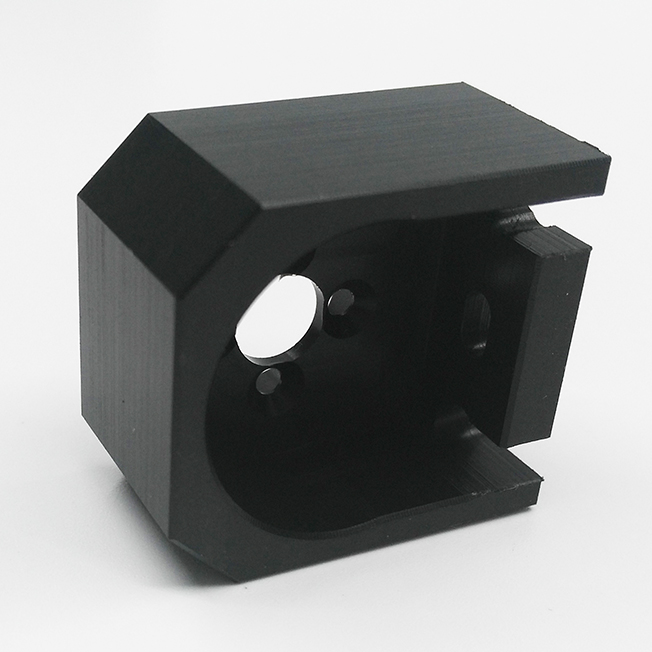

We provide high quality plastic cnc service.The technician can control the deformation in plastic machining very well,Product accuracy 0.01mm. Machining plastic Process,Since the hardness of the plastic is low, the machining amount is small.Plastic thermal conductivity is poor, high temperature will melt the plastic,So with a lower cutting speed,While increasing the impact of cooling fluid.

Our plastic machining includes:delrin, neoflon, teflon, ultem, peek, PC ,PMMA, PTFE, PEI,, POM, ABS.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC machining parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC milling,CNC turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

As a custom CNC machining shop, we machine specialty parts out of any specified material, from standard to exotic. Some of the standard materials from which we CNC Milling machining include aluminum, copper, brass, and steel, as well as plasti.Our knowledge and experience in processing a wide variety of materials makes it the ideal choice for the you required part.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.From the procurement of raw materials to CNC machining parts shipments, we have established a complete set of quality control system. The whole process of operating workers by SOP operations, IPQC products for each processing steps to detect, Make sure the product meets the requirements before proceeding to the next CNC machining Turning.And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report. Engineering and technical personnel on a regular basis for processing and maintenance settings, timely update processing tool. Our inspection tools are:Digital caliper, Micrometer Calipers,height gauge,Profile projector,Tolerances can be measured +/-0.01mm and 0.001mm.

Related Keywords