High Purity 95% Al2O3 Brown Aluminium Oxide

-

$10.00≥1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 13000/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

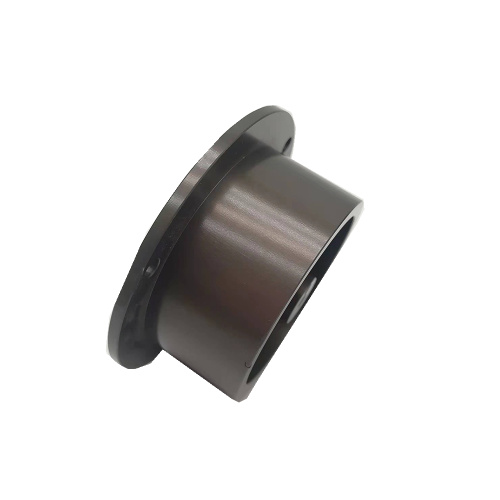

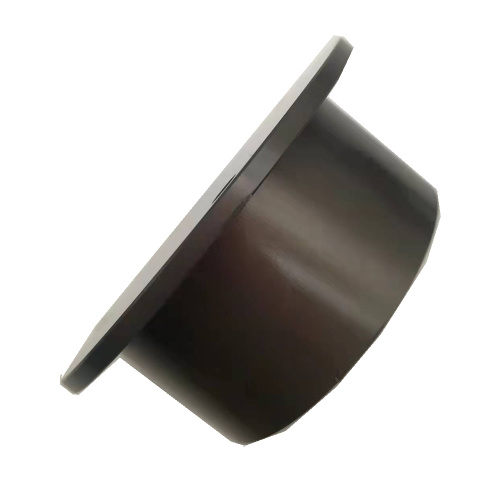

This product adopts anodic oxidation process, electrochemical oxidation of metal or alloy. Aluminum and its alloys form an oxide film on aluminum products (anodes) under the action of applied current in the corresponding electrolyte and specific process conditions. Anodic oxidation, if not specifically specified, usually refers to sulfuric acid anodizing. In order to overcome the surface hardness The surface treatment technology has become an indispensable link in the use of aluminum alloys, and the anodic oxidation technology is the most widely used and successful.

.

Precautions for anodizing process:

1: Properly control the process conditions of anodic oxidation, including solution temperature, voltage and time.

2: Attention shall be paid to the dyeing process. The washing of workpieces before dyeing shall be strengthened. The workpieces shall be dyed immediately after anodizing, and the workpieces shall not be overlapped. The washing after dyeing shall be strengthened.

3: Carefully clean and pack the workpiece, and carefully disassemble the workpiece to avoid white scratches. Do a good job in the drying process of the product. It is better to use soft and clean paper for packaging, and package them one by one to prevent mutual scratching.

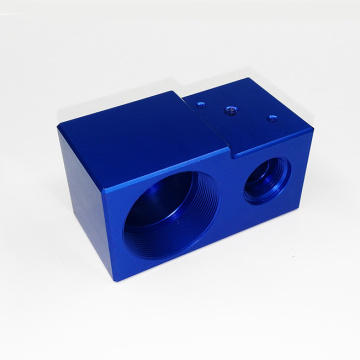

Fast delivery is our advantage, machining aluminum parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC machining center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day

We are a professional custom mold manufacturer. We support all kinds of non-standard customization. CNC machining can import quasi-stereoscopic 3D image files, PDFS and IGES, STEP or SOLIDWORKS files. Please send your 3D artwork and PDF for the best quote.

Related Keywords