properties of anodic aluminium oxide

-

$10.00≥1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 13000/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

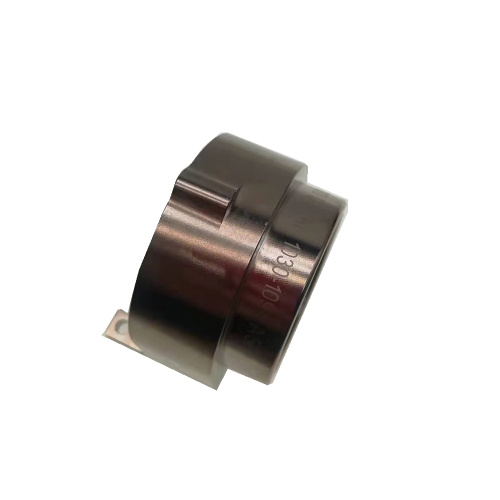

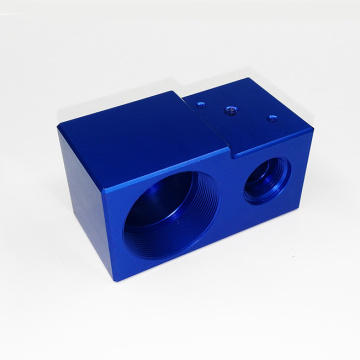

The production process of aluminum oxide adopts a unique anodizing treatment, which is a breakthrough in the electrochemistry bright treatment technology. It can effectively protect materials from corrosion, is anti-static, does not dust and is easy to clean, is fireproof, has excellent oxidation resistance, and the anodized process surface never falls off. It is especially suitable for enterprises to choose at home. It is gradually becoming a new leader in the numerical control industry. It has high requirements for technology and high price. As the surface is fine and smooth and does not change color, it is the most resistant to cleaning among the three categories. It can be mainly divided into anodic aluminum oxide oxide film and aluminum oxide obtained by ordinary chemical oxidation treatment:

.

The structure and surface of this product are anodized, which can have a very beautiful color after increasing the oxidation resistance and friction resistance of the surface. This product needs to have a certain degree of precision, because it also needs other parts to be assembled together, which is also the reason why this product adopts the relatively expensive machining method. In the actual working process, whether the product can operate normally is closely related to the accuracy of the parts. Therefore, in each processing enterprise, there are certain requirements for the precision and accuracy of parts processing, and we strive to control the errors as much as possible in the processing process and reduce the errors in the work, so that the precision of parts can obtain products with very good quality effects.

Fast delivery is our advantage, machining aluminum parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC machining center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day

We are a professional custom mold manufacturer. We support all kinds of non-standard customization. CNC machining can import quasi-stereoscopic 3D image files, PDFS and IGES, STEP or SOLIDWORKS files. Please send your 3D artwork and PDF for the best quote.

Related Keywords