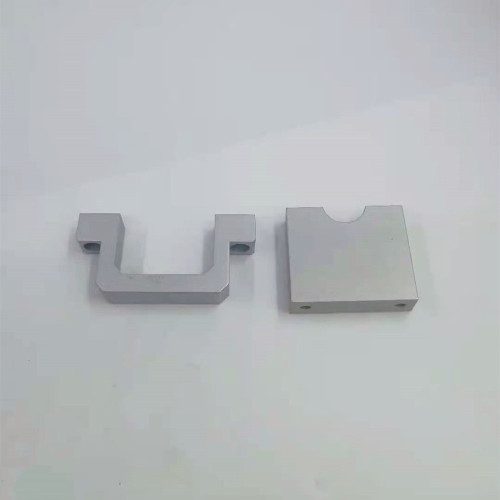

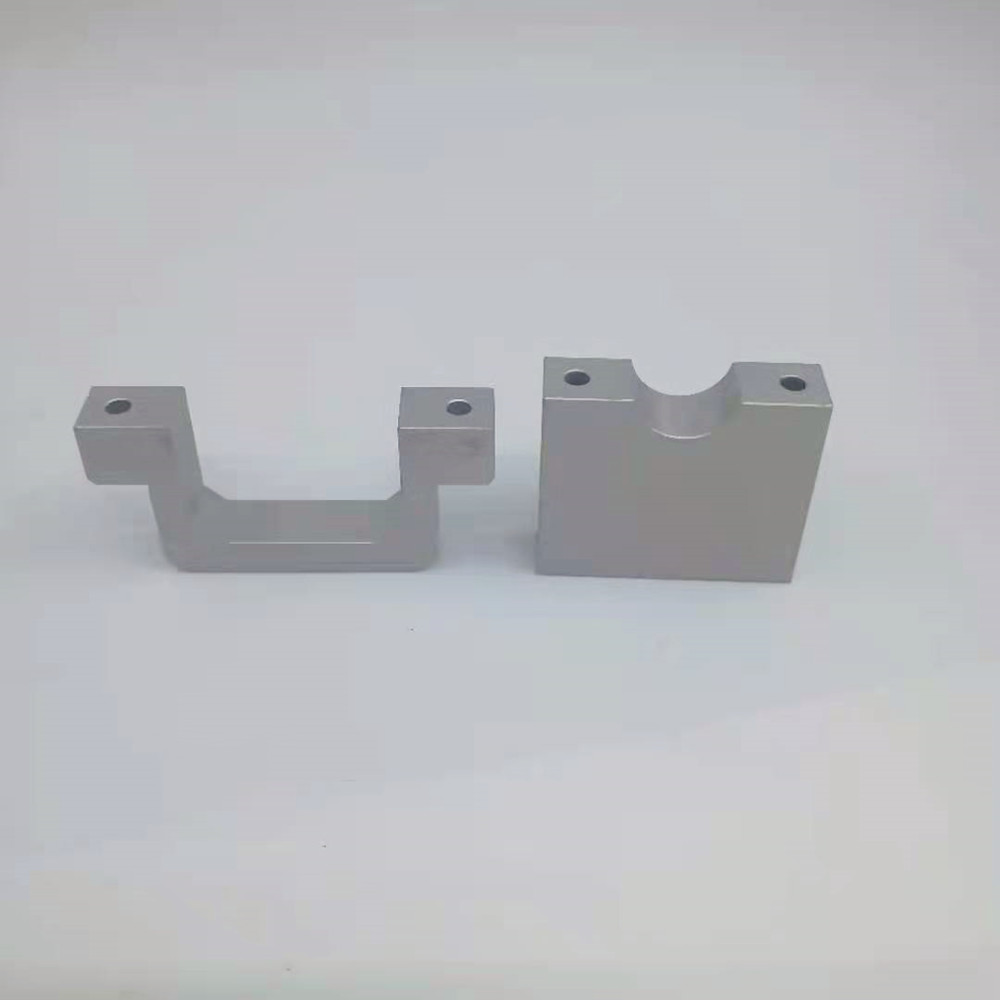

Customized CNC machining aluminum small parts

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 4600/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Customized CNC machining aluminum small parts

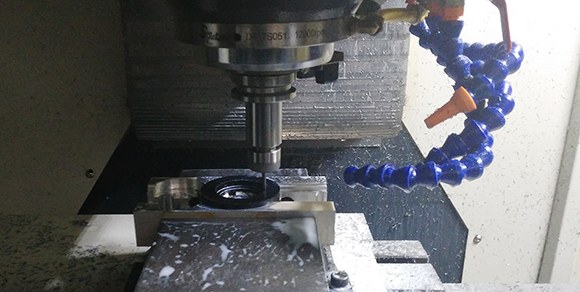

Aluminum die-casting is a kind of pressure-casting parts. It uses a pressure-casting mechanical die-casting machine equipped with a casting mold to pour the heated liquid aluminum or aluminum alloy into the inlet of the die-casting machine. The die-casting machine is die-casted and the mold is cast out. The shape and size of aluminum parts or aluminum alloy parts, such parts are usually called aluminum die-casting.

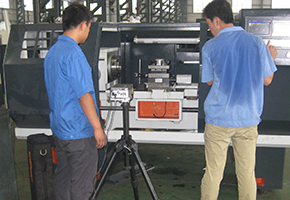

2. Material cooling problem. The workpiece may deform after cooling. This situation is often difficult to avoid. In this case, special attention should be paid to the use of coolant. On-site measurement should also consider the possibility of material deformation.

3. Processing Technology. Unreasonable processing technology can easily cause workpiece size errors. The use of fixtures should be on the basis of ensuring the basic process details of milling CNC machining (RYH(Hongkong) Aluminum Products, such as "thickness and then fineness, surface and hole, large and then small" or "reduce the number of fixtures, try to use modular fixtures ”) to minimize the machining errors caused by aluminum chips on aluminum parts.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Related Keywords