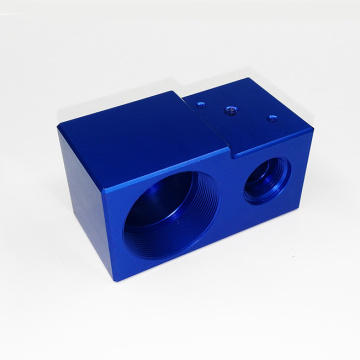

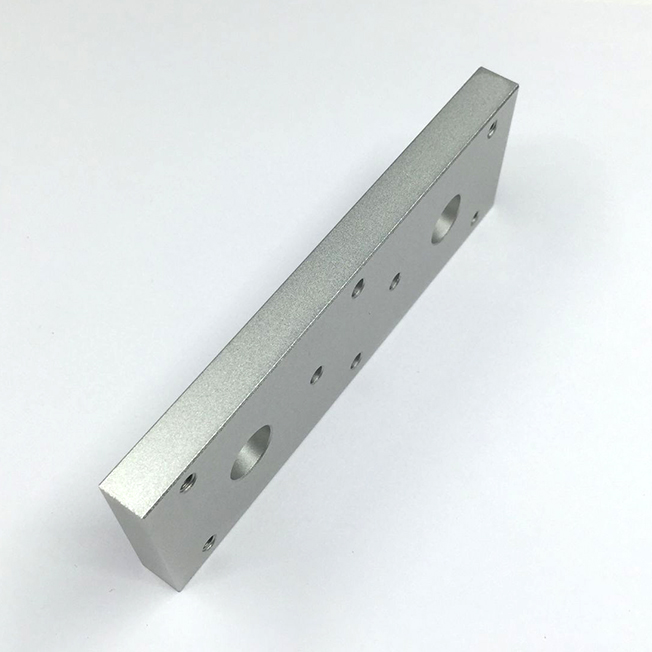

Milling Machining Aluminum Parts And Accessories

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 3 Days

- Transportation:

- Air

- Port:

- Hong Kong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 4600/Month |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Air |

| Port: | Hong Kong |

Advantages of CNC Machining Aluminum Products Technology

In recent years, in the process of metal milling machining, the machined aluminum parts and accessories are gradually increasing, and the shape is becoming more and more complex, and the requirements of dimensional accuracy and roughness are getting higher and higher. In small margin finishing milling aluminum alloys, the indexable blade edge is usually blunt, which often leads to the "ploughing" effect, the sudden increase of cutting force, the problem of too large cutter and too high power demand. Therefore, when milling aluminum alloys, it is necessary to improve the sensitivity of the blade and increase its power in order to avoid this defect as much as possible.

Our factory provide CNC machining service for custom CNC machining parts, turning parts, springs, cold forming parts, screw machined parts. We can produce CNC machined parts according to your requirements.

CNC Machined parts include: Hydraulic, valve, flange, automobile, shaft, bearing housing bar, plate,welded part, marine part, winch part, sheet metal

CNC Milling Materials: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45#, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304,( 57313915, 57310628, 57273318, 57271601, 57242800, 57167502, 57157481, 57153047, 57150572, 56726168, 56719311, 56712752, 56532120, 56393431, 55840789,1.4301), SUS316. Brass/ copper / bronze. Plastic: PEI (Ultem), POM, Teflon, PA,( 57313916, 57310629, 57273319, 57271602, 57242801, 57167503, 57157482, 57153048, 57150573, 56726169, 56719312, 56712753, 56532121, 56393432, 55840790, PA66 ) PC, PMMA (Acrylic), PEEK, Nylon etc..

Equipment: Common lathe, CNC Machine, Milling, Turning, Spring Machine

Metal Process: CNC turning, CNC milling, cutting, drilling, planning, grinding, welding.

Surface Treatment: anodize (clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO, Zn plated, Cr /Ni plated, hot-dip galvanizing, paint, powder coating, brush, polish.

Files of drawings: CNC Machining can import your PDF, CAD, IGES, STEP, STP, X-T files. Please send us your drawings for a quote. We will reply you as soon as possible.

Technical: Dedicated mechanical designer, experienced worker 3D design service inclusive of modeling, analysis and detailed drawing at normal cost. We have a professional team of CNC machining technology, accumulated a lot of experience in machining .Our technical team will review each drawing and arrange each machining step, set the parameters of the CNC machining center. We also have set up a special sample production team to provide small quantities of machining services.

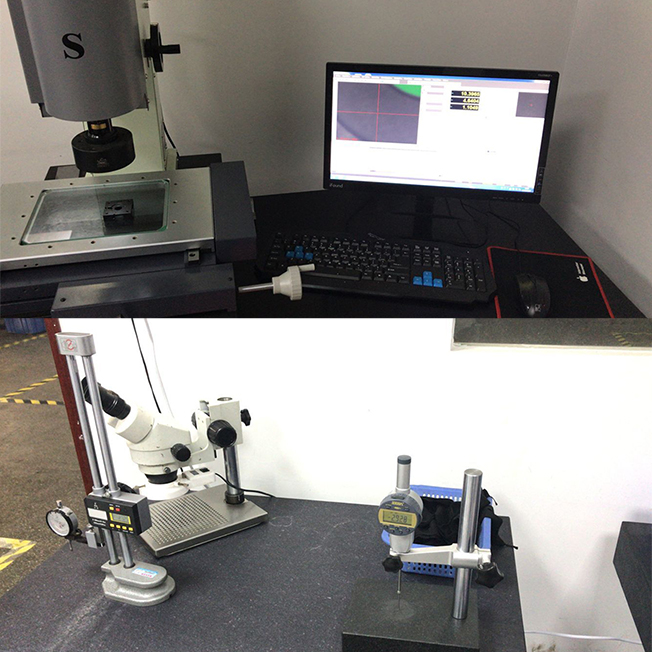

Quality: Pass ISO 9001: 2008. We use ISO9001:2008 quality system certification to ensure the quality of products. Quality personnel are measuring the size of each piece of machining products, measuring instruments include Digital caliper, Micrometer Calipers, height gauge, Profile projecto, these measuring instruments regularly through the third party laboratory calibration, the measurement accuracy is 0.001mm. In order to improve the speed of the inspection, the engineer designed a precise auxiliary inspection fixture. We can provide the dimensional measurement report of machining parts.

Delivery: Fast delivery is our advantage. We can finish the sample of turning parts in 3 days. If you need, we can finish sample machining in one day, and also provide emergency machining service. Our factory offers 2~3 CNC Turning Center, which is specially used for machining samples. The workers in our factory are divided into two groups to ensure that the machine is producing the product for 24 hours.

Packing: According to the products' requirements

If you want to know more about precision CNC machining service, Please contact us.

Related Keywords