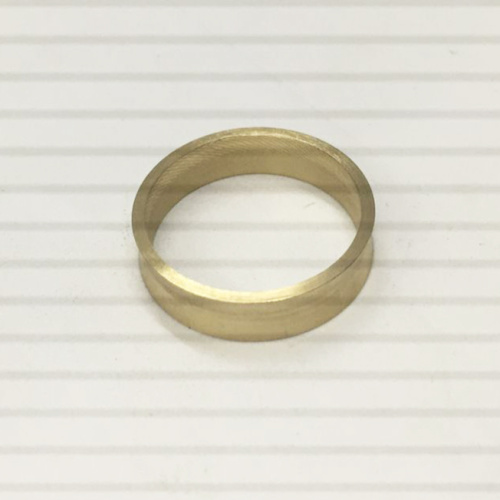

Precision Machining Bronze Components

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Precision Machining Bronze Components

Bronze originally refers to copper tin alloy, but in industry, the copper alloy contains aluminum, silicon, said lead, beryllium, manganese are also used to called bronze, so bronze actually includes tin bronze, aluminum bronze, beryllium bronze, silicon bronze, lead bronze etc.. With the addition of these alloying elements, the strength of bronze has been greatly improved, and the bronze suitable for plasticity machining is machining bronze. The deformation resistance of bronze is large, which brings some difficulties to the machining. But at the same time, copper has some specific functions, such as high elasticity, softening resistance, high corrosion resistance, high wear resistance and so on. Thus greatly expanded the application field of copper, become the support of new technology.

We provide CNC machining prarts that meet the performance, quality, reliability, and safety requirements of our customers. And the design of reasonable detection fixture to ensure more efficient testing.

We offer industry-leading custom CNC turning and milling machining. Our precision parts serve medical, communications, aerospace, unmanned aerial vehicles, robots and so on. We providing the best CNC turning and CNC horizontal / vertical milling services. We have advanced CNC lathe and milling machine, the machining accuracy can meet the tolerance of ±0.01mm.

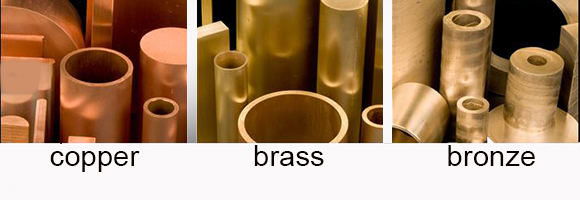

We have three types of machining copper: copper, brass, bronze.

CNC machining including CNC milling and CNC turning, cutting, grinding, milling, sheet metal fabrication. CNC milling machining and CNC turnining materials are: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45 #, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304, (1.4301), SUS316. Brass/ copper / bronze. Plastic: POM, Teflon, PA, ( PA66 ) PC, PMMA. Product surface treatment: anodize (clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send your 3d work and PDF for a quote.

Related Keywords