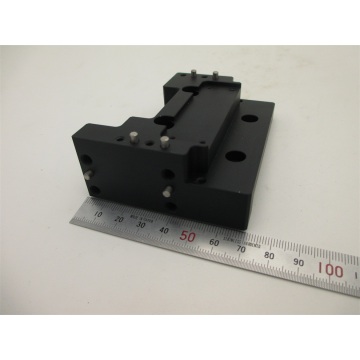

CNC Machined A2017 High Precision Turning Parts

- Payment Type:

- T/T, Western Union

- Incoterm:

- EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 200,000pcs/ month |

| Supply Ability: | 200,000pcs/ month |

| Payment Type: | T/T,Western Union |

| Incoterm: | EXW |

| Transportation: | Ocean,Land,Air |

Die Casting Machining are widely used in automotive automation equipment. You may choose steel ,alumonum, brass, bronze or other plastic materials for your Aluminum Conventional Milling. Surface treatment for high precision turning parts is available for us like: hard anodize, polishing; non-electrolytic nickel, hard chrome plated. If any new RFQ, pls cotact SGI.

1. Materials that are available for metal welding tools fabrication

Fe: Fe360/ 1045/ 1049/ P20/ S136/ M2/ H13/ D2/ 440C/ 4140/ O1

Stainless Steel: 303/ 304/ 316

Al: 2017/ 5052/ 6061/ 7075

Cu: C11000/ C27400 /C34200/ C17200

2. Surface finish available for metal welding tools fabrication

Laser-printing, clear/ black anodizing, zinc plating, chrome plating, electroplating and nitriding are common treatments in SGI factory

3. QC Team

4. Files formats accepted when clients send us drawing for metal welding tools fabrication

3D: Pro/E . UG . MasterCam

2D: AutoCad

Accepted file format: .igs .prt .stp .x_t .dxf .dwg .pdf .jpg .tif .jpg .bmp .doc .xls.

5. How to have our fabrication service

Step 1: provide your drawing and requirements to us.

Step 2: we make quotation.

Step 3: negotiation and confirm product details.

Step 4: confirm parts cost, freight and delivery.

Step 5: provide PI to you, you make payment accordingly.

Step 6: we start production, and keep you informed updated news.

Step 7: send you details and photos when qualified sample is finished.

Step 8: make shipment after above information is confirmed.

6. Delivery for metal welding tools fabrication

DHL, FedEx, UPS for small kilos(2- 3 days); By sea for big kilos( 30 days).

7. Packing

Related Keywords