Vacuum distillation equipment for Pharmaceutical Industry

-

USD4699≥1 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Productivity: | 500set |

| Supply Ability: | 10 sets per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO14000,ISO9001,Ex,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

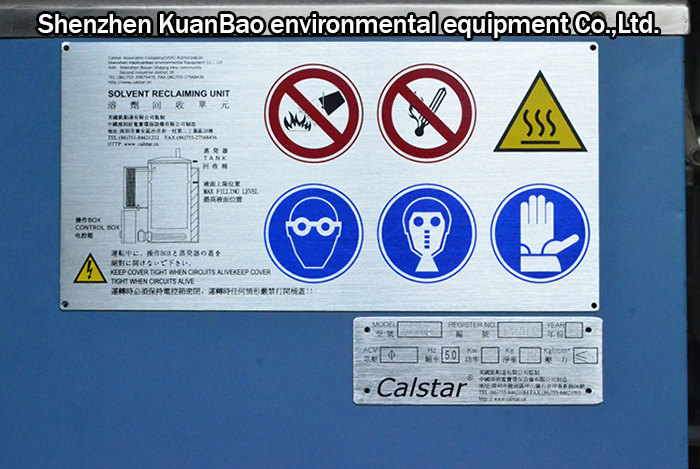

Vacuum distillation equipment for Pharmaceutical Industry

Calstar are one of the well-known exporter, manufacturer and supplier of vacuum solvent recycling equipment. Calstar offered vacuum distillation is used to vapourise high boiling point, easy to decompose organic solvents.

Vacuum decompression device

Vacuum decompression device, special auxiliary device, use for organic solvent recovery, removeble and safe structure, pneumatic operation, is manufactured according to Chinese explosion-proof standards (CNEX) and European standards(ATEX).Vacuum decompression device is suit for suitable for assembling with Calstar organic solvent recycling machine 10L/20L/25L/30L/40L/60L solvent recycling machine.The vaccum decompression recovery device can realize the high recovery rate and high safety permance . The vacuum decompression is a automatic effiux device ,it can reduce boiling point of product up yo 30% and it is seal completely so that no solvent leakage can be allowed in.what's more,the vacuum decompression device can expedite recovery speed by 1/3.even more,The vacuum degree can reach to 600mmHg.

Characteristic

●Explosion-proof electric equipment: in compliance with Chinese safety standards (CNEX) and European standards (ATEX), worry-free and safe for use;

●High quality durable stainless steel tank, prevent chemical corrosion;

●Operation is simple, convenient, easy and simple; no power supply, pneumatic operation, automatic feeding, safty for use;Vacuum and vacuum equipment,Vacuum relief device function,Effect of solvent recovery pressure reduction equipment

●Vacuum decompression recovery: condensation, vacuum, storage features and variety of functions in one machine; heating temperature is low, saving heating electricity; sealed recycling, reduces evaporation, prevents leakage; right volatility and easy to decompose, toxic or high boiling point solvent recovery with excellent effect;

●The equipment is compact, small and light, space saving; removable device, easy operation and installation.Vacuum and vacuum equipment,Vacuum relief device function,Effect of solvent recovery pressure reduction equipment

Specifications

(For reference, the data

subject to change, please with your choice models the actual date)

|

Capacity |

Vaccum Pump |

Diaphragm Pump |

Dimension |

Weight |

|

60/90L |

95L/min |

0~61L/min |

630X420X1290 |

51kg |

Calstar is an ISO 9001 : 2008 certified & an ISO 14000 : 2008 certified company and approved outsourcing company, Calstar `s Founded in 20-July-2001 , Ensure now enjoys a Strong National and international reputation – working with customers from different countries such as the China, USA, UK, Australia and many more.

Calstar is a pioneer and leader in manufacturing of high quality Solvent Recovery System established in 2001. Best of all, Calstar supports these products over 16 Year Solvent Recovery System Experience along with 30000 satisfactory Customer Installation.

Calstar has always been a precursor in introducing the most innovative and revolutionary products that can offer the most futuristic machines to its customers. We undertake to offer consultancy and services for establishing turnkey projects by way of Solvent Recovery System integration in these lines. Every member of the Innovative Solvent Distillation Unit remains unified in achieving these goals.

Related Keywords