Explosion Proof Solvent Recycling machines

-

USD4599≥1 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Productivity: | 500set |

| Supply Ability: | 30 sets per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO14000,ISO9001,Ex,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Explosion Proof Solvent Recycling machines

Explosion Proof Solvent Recycling units

Explosion Proof Solvent Recycling system

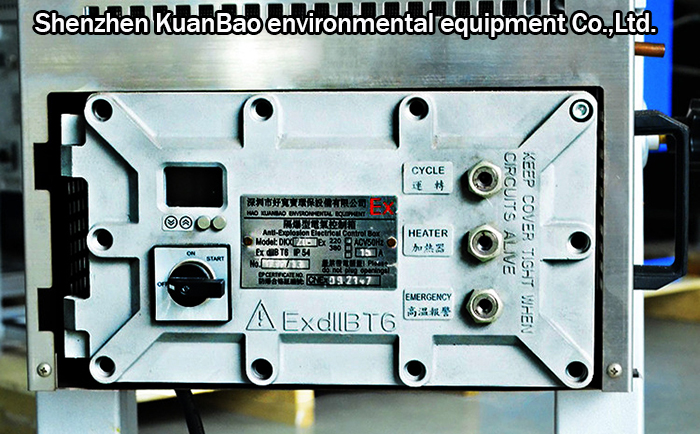

A20Ex Explosion Proof Solvent Recycling machines

A20Ex is a special equipment made for organic solvent recycling. It has a tilting-type air-cooled condensing system, quality build, and is manufactured according to Chinese explosion-proof directive (CNEX) and European directive (ATEX). The organic solvents are recycled through distillation and cooling.

It is suitable for recycling a small amount of organic solvents.

The contaminated solvents will be recycled after a few hours, ready use!

Customer Benefits

· High quality solvent recycling: clear, pure, good performance;

· Low maintenance cost, easy to maintain;

· Easy operation and installation: recycling process and operation are simple. After short-term of training, normal workers are able to operate.

· The equipment is compact, small and light, space saving;

· Short processing time and fast operation time;

· Low investment, quick return on investment.

Characteristic

· Explosion-proof electric equipment: in compliance with Chinese safety directive (CNEX) and European directive (ATEX), worry-free and safe for use;

· In-house developed, standardized production, stable and durable quality assured, good performance;

· Tilting-type: gradually tilt and pour out residue, easy residue removal;

· High quality durable stainless steel tank, prevents chemical corrosion; two-tiered structure, indirect heating, reinforced barrelhead design, precise temperature control, explosion-proof, anti-leakage;

· Heating Method: heating medium (heat transfer oils) indirect heating;

· Digital heating temperature controller: advanced numerical performance, intuitively secure, accurate and convenient heating temperature control;

· Multiple operational safety protection functions:

Pre-set temperature shutdown; Timer shut off; Ultra-high temperature protection;

High-voltage protection; Power failure protection.

Customizing & Auxiliary device:

※You are free to customize the equipment to meet your specific needs, or choose auxiliary device in compliance with your needs in order to achieve the desired treatment effect.

Technical Parameters:

(for reference, the data subject to change, please check with your choice models date).

|

Model |

Volume |

Heating Temperature |

Socket Power |

Time per Cycle |

Dimension |

Weight |

|

A20Ex |

21L |

50~190°C |

220ACV/50Hz |

2~3Hr |

790*535*1240mm |

93kg |

NOTE: Values listed above, the recovery time is under ideal conditions in laboratory test values during recovery of toluene for reference.

Application Fields:

Calstar ® solvent recycling machines are suitable in recycling most of common organic solvents used in various industries. The equipment is being widely used in various industries inland and abroad accommodating to wide range of solvent recovery and treatment needs.

1. Automobile manufacturing and repairing industry:

Pipeline cleaning solvents for vehicle spraying equipment and spray gun, such as: Acetate,ester,chlorform tri-Chloro-Ethane, iso-Propyl Alcohol Ethyl Ketone (MEK),Petroleum solvent ,(Mineral Oil),naphtha, toluene, xylene, methyl ethyl ketone, n-butyl, mixture organic solvent.;etc.; Solvent for cleaning the petrol remains in engines.

2. Electronic product manufacturing industry (e.g.: LCD, LED, etc.):

Organic solvents for mould cleaning and electronics cleaning, such as: ethanol, acetone, trichloroethylene, etc.

3. Precision instruments and hardware manufacturing industry:

Organic solvents for mould cleaning and products processing, such as: naphtha, hydrocarbons, kerosene, gasoline and other solvents.

4. Sports Equipment Manufacturing:

Detergents for soluble wax casting, such as golf-heads and fishing-rods; solvents for spraying and cleaning golf-sticks and fishing-rods.

5. Footwear industry:

All kinds of organic solvent for spray equipment cleaning, such as equipment for spraying shoe outsoles, heels, processing and cleaning upper print of shoes.

6. Plastic products:

Organic solvents for cleaning and processing, such as: cleaning solvents used in printing.

7. Printing industry:

Detergents for cleaning printing-plates and machines, such as: plate washer solution, car washing solution.

8. Paint Manufacturing Chemical industry:

Organic solvents and paint-mixing solvents for cleaning the production equipment, vessels and bottling equipment, such as: Acetate, ester, chloroform, tri-chloro-ethane, iso-propyl alcohol ethyl ketone (MEK), petroleum solvent, (mineral Oil), naphtha, toluene, xylene, methyl ethyl ketone, n-butyl, mixture organic solvent and so on.

9. FRP products industry:

Solvents, which are used during surface anti-corrosion process and artistic coating process, such as: yacht manufacture, wind turbine blade manufacture.

10. Etching:

Solvents for surface pre-treatment cleaning and electroplating pre-treatment.

11. Optical products:

Solvents, which are used during production of the components, and solvents for pre-treatment of coating.

12. Furniture Manufacturing:

Organic solvents for cleaning spraying equipment and paint-mixing, such as: naphtha, xylene, methyl ethyl ketone, acetone and so on.

13. Other industries that use organic solvents as cleaning agents.

Explosion Proof Solvent Recycling machines

Explosion Proof Solvent Recycling units

Explosion Proof Solvent Recycling system

Not suitable for the following solvent recovery solution types:

1. Nitrocellulose (nitro), and oxidant and other hazardous solvents;

2. Strong acid or strong alkaline solvents;

3. Highly toxic solvents;

4. Solvents, which can strongly corrode stainless steel and/or copper pipes.

Explosion Proof Solvent Recycling machines

Explosion Proof Solvent Recycling units

Explosion Proof Solvent Recycling system

Related Keywords