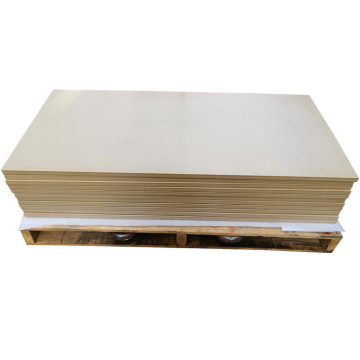

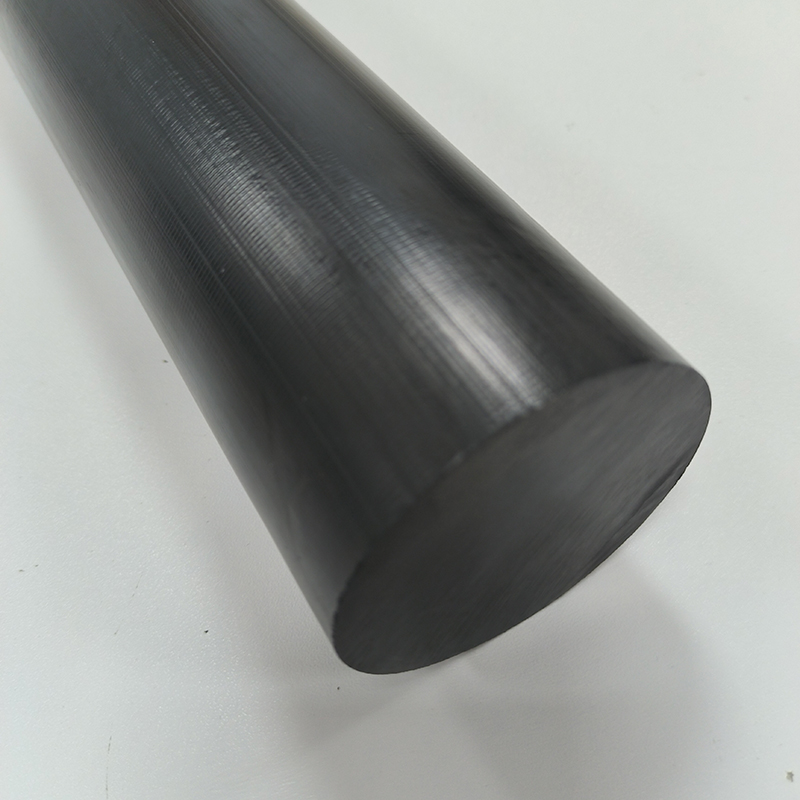

PEEK Hpv10%Carbon Fiber 10%Graphite 10%Ptfe

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Product Composition

Material base polymer:

PEEK polymer (as the main substrate/matrix material)

Functional additives (10% each):

Polytetrafluoroethylene (PTFE)

▪ Function: significantly reduce the friction coefficient and improve wear resistance

Graphite (Graphite)

▪ Function: provide self-lubrication and enhance high temperature stability

Carbon Fibres (Carbon Fibres)

▪ Function: improve mechanical strength, stiffness and dimensional stability

Performance Characteristics

1. Superior Wear Resistance

10% graphite: Provides a solid lubricating layer to reduce surface wear

10% carbon fiber: Enhances matrix hardness and resists abrasive erosion

Result: Significantly extends the service life of bearings/sliding parts

2. Ultra-Low Friction Coefficient

10% PTFE: Forms a self-lubricating film on the friction surface, reducing the dynamic friction coefficient by 40-60%

Result: Reduces energy consumption and heat accumulation, suitable for high-speed sliding scenarios

3. Enhanced Strength & Stiffness

10% carbon fiber: Improves tensile strength (+30% or more) and elastic modulus

Result: Load-bearing capacity is better than pure PEEK, resists deformation and fatigue

4. High Dimensional Stability Stability)

Carbon fiber + graphite composite network: inhibit thermal expansion (reduced linear expansion coefficient)

Result: precision parts maintain tolerance accuracy (±0.05mm level) under temperature fluctuations

5. High-Temperature Performance

Base material PEEK temperature resistance 260℃ + additive synergy:

PTFE guarantees high-temperature lubricity (up to 250℃)

Graphite improves thermal conductivity and reduces local overheating

Result: maintain more than 80% of mechanical properties under 200℃ working conditions

Advantages

1. Triple synergistic wear resistance

10% carbon fiber: Strengthen the deformation resistance of the matrix

10% graphite: Continuously provide a self-lubricating layer

10% PTFE: Significantly reduce the dynamic friction coefficient

→ Wear rate is reduced by more than 85% compared to pure PEEK

2. Zero lubrication operation capability

Additives synergistically form a permanent lubricating film

Eliminating grease pollution (applicable to medical/food grade scenarios)

3. High load and high temperature stability

Limit PV value>3.5 MPa·m/s(increased by 337%)

-50℃~+250℃ Maintain dimensional accuracy (expansion coefficient <3×10⁻⁵/K)

4. Professional scenario customization

Specially optimized for bearings/sliding parts:

Anti-fretting wear

Anti-creep fatigue

Resistant to chemical solvent erosion

Application Fields

1. High-load bearing system

Applicable scenarios:

Oil-free lubricated bearings (such as food processing equipment bearings)

Heavy-loaded rotating bearings (engineering machinery spindles)

2. Precision sliding parts

Typical applications:

Semiconductor equipment guide rails

Medical implant sliding joints

3. Corrosive environment wear-resistant components

Irreplaceable scenarios:

Chemical pump valve sealing rings (acid and alkali/solvent resistant)

Fuel system slides (resistant to gasoline and diesel corrosion)

Our company is deeply engaged in the field of high-performance engineering plastics and insulation materials, and is committed to providing innovative material solutions for the global high-end manufacturing industry. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance, and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

FAQ

Q: Compared with unfilled pure PEEK, what are the advantages of PEEK5600LF30?

A: Adding 10% carbon fiber + 10% graphite + 10% PTFE triple reinforcement, the compressive strength is increased by 40%, and the wear resistance is increased by 50%, which is more suitable for high-load bearing applications.

Q: What is the difference compared with ordinary carbon fiber filled PEEK?

A: Ordinary products only enhance rigidity, while PEEK5600LF30 adds PTFE+graphite, which reduces the friction coefficient by 35%, achieving self-lubrication and zero-stuttering operation.

Q: Compared with ceramic-based bearing materials, what are your advantages?

A: Ceramics are brittle and expensive, PEEK5600LF30 is 60% lighter, more resistant to chemical corrosion (acid, alkali, solvent), and 200% more cost-effective.

Q: How does it compare with stainless steel bearings?

A: Stainless steel needs regular oiling and maintenance. PEEK5600LF30 has a PTFE+graphite self-lubricating formula that extends its life by 3 times, is maintenance-free and saves costs.

Q: Compared with graphite-based materials, what breakthroughs are there in performance?

A: Graphite materials have weak mechanical strength. PEEK5600LF30 has a carbon fiber reinforced matrix, which increases its deformation resistance by 70% and achieves dimensional stability of ±0.02mm.

Q: What are the advantages compared with single-additive PEEK (such as PTFE only)?

A: The performance of a single additive is limited. PEEK5600LF30 has a triple compound formula: carbon fiber pressure bearing + graphite lubrication + PTFE friction reduction, and the overall performance is improved by 55%.

Q: Compared with engineering plastics such as nylon (PA66)?

A: Nylon is only resistant to 120°C, while PEEK5600LF30 is resistant to 260°C. Its strength retention rate at high temperatures exceeds 90%, making it suitable for extreme working conditions.

Q: What are the core differences compared to metal materials?

A: Metals are prone to corrosion and are heavy. PEEK5600LF30 is lightweight (density 1.45g/cm³) and has electrical insulation properties, eliminating the risk of current corrosion.

Q: What is the difference compared to ordinary plastics (such as PP/PE)?

A: Ordinary plastics have low hardness (Rockwell hardness <100), while PEEK5600LF30 has a hardness of 110 HRR, is wear-resistant and scratch-resistant, and has an 8-fold increase in load-bearing capacity.

Q: Compared with other special engineering plastics (such as PPS/PI), what is the cost-effectiveness?

A: PPS/PI is expensive (about 2 times), PEEK5600LF30 achieves 30% cost optimization with the same level of performance and has better fatigue resistance.

Related Keywords

Related Keywords