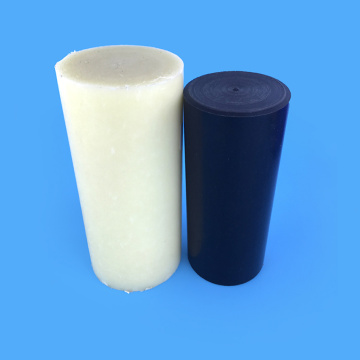

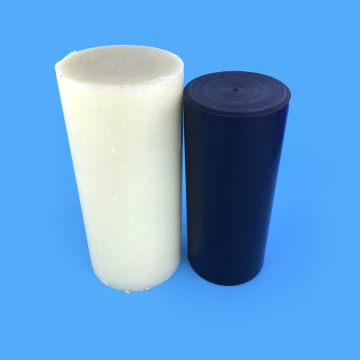

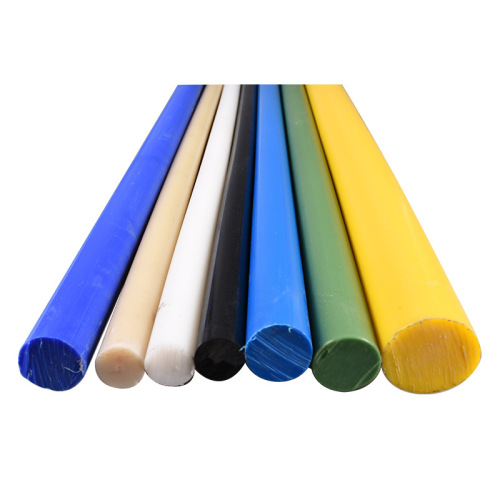

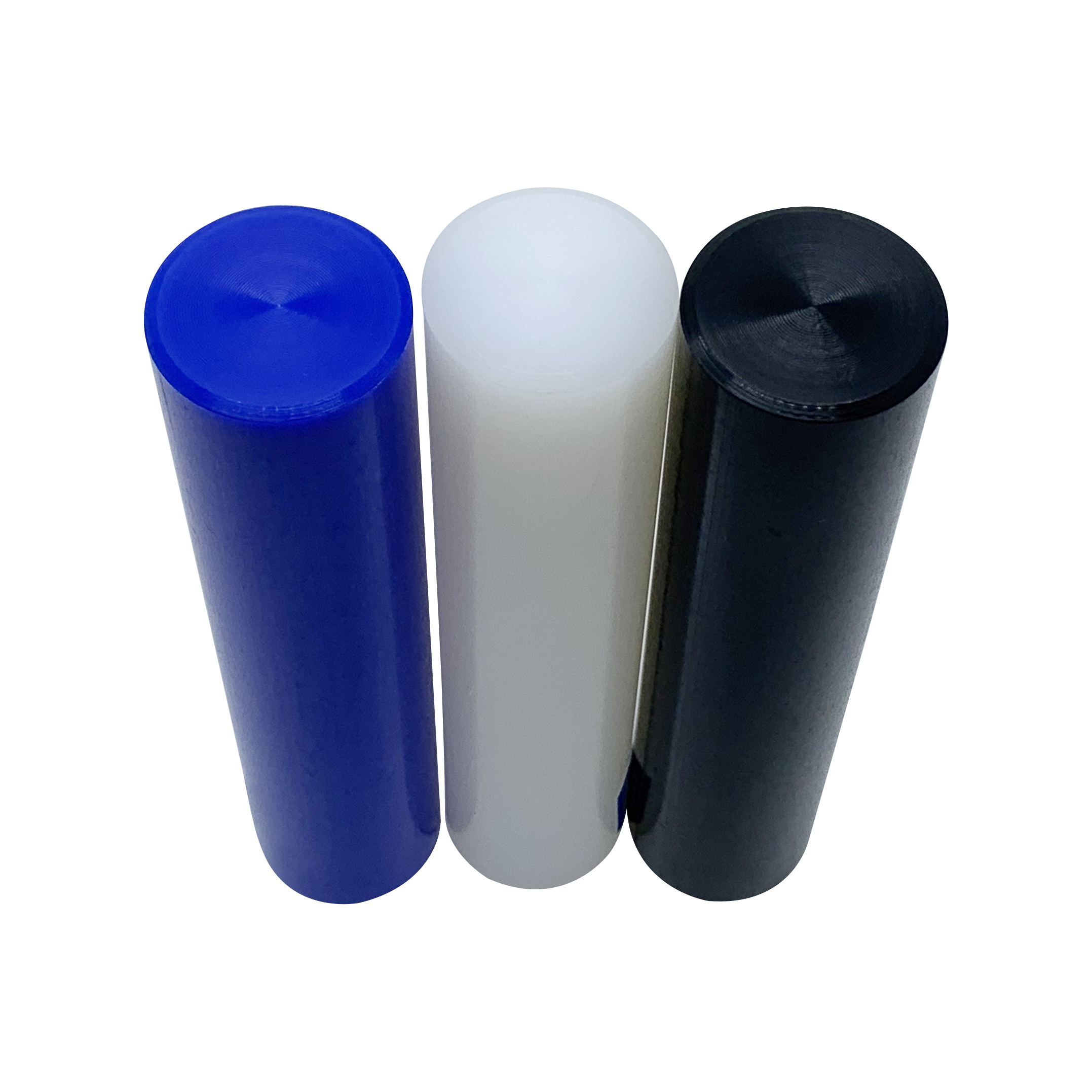

Customizable PA6 Nylon Rods for Industrial Applications

$3.68 - $4.18/Kilogram

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | 20Tons/month |

|---|---|

| Supply Ability: | 20Tons/month |

| Payment Type: | T/T,D/A,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ROHS |

| HS Code: | 3920920000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

PA6 Nylon Rod: Composition & Production Process

PA6 (Polyamide 6) is primarily composed of caprolactam monomers, polymerized via ring-opening polymerization to form long-chain polyamide structures.

Production Process:

Raw Material Preparation: Caprolactam is purified and dried to remove moisture.

Polymerization: Melted caprolactam undergoes ring-opening polymerization in a reactor, forming PA6 resin.

Extrusion: The resin is melted (230–280°C) and extruded into rod shapes through a die, followed by rapid water cooling to solidify.

Post-Processing: Rods are annealed to relieve internal stress and dried (80–120°C) to stabilize dimensions. Optional modifications (e.g., glass fiber reinforcement) are added during extrusion.

PA6 Nylon Rod: Key Properties and Applications

Performance Characteristics:

PA6 nylon rods exhibit high strength and toughness combined with excellent wear resistance and self-lubricating properties, making them ideal for dynamic friction components. They resist oils, weak alkalis, and some solvents but degrade under strong acids or oxidizers. With a melting point of ~220°C, they operate stably at 80–120°C but soften at higher temperatures. Their notable hygroscopicity (3% moisture absorption) causes dimensional and electrical instability, requiring pre-drying or humidity-controlled environments.

Primary Applications:

Industrial: Gears, bearings, and sliding parts in machinery.

Automotive: Engine covers, wiper components, and fuel system connectors.

Electronics: Insulating parts (e.g., terminal blocks) in low-humidity settings.

Consumer Goods: Sports equipment (ski bindings) and medical tool handles.

Modified Grades: Glass/carbon fiber-reinforced PA6 rods enhance structural rigidity for heavy-load applications.

Balancing cost-effectiveness, processability, and performance, PA6 rods are widely adopted in lightweight, wear-resistant, and chemically moderate environments.

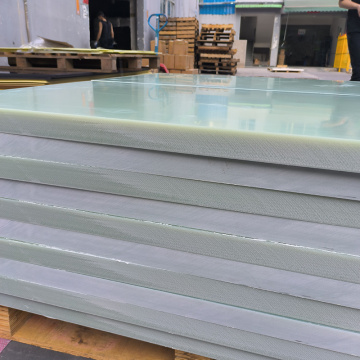

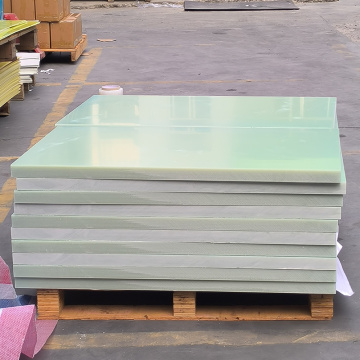

Our company focuses on high-performance engineering plastics and insulation materials. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

Related Keywords

Related Keywords