Efficient FRP Sheets for Corrosive Environments

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

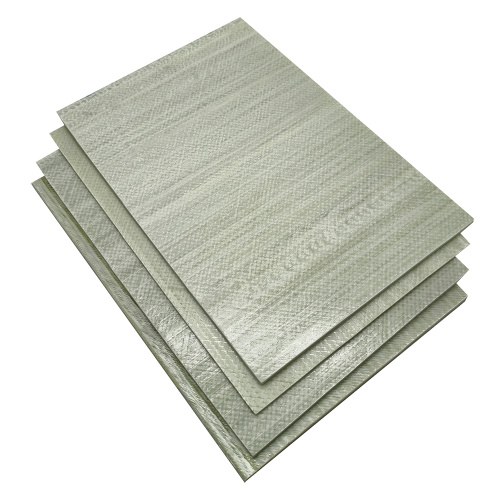

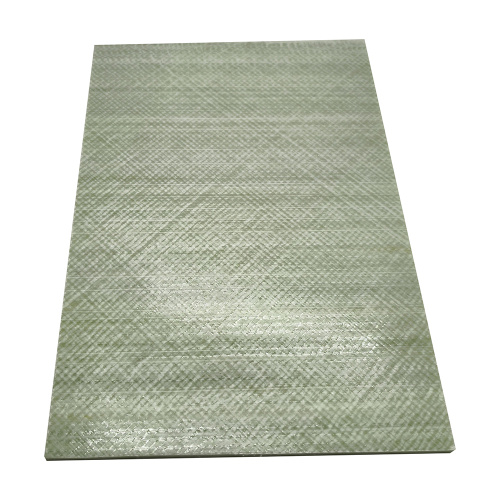

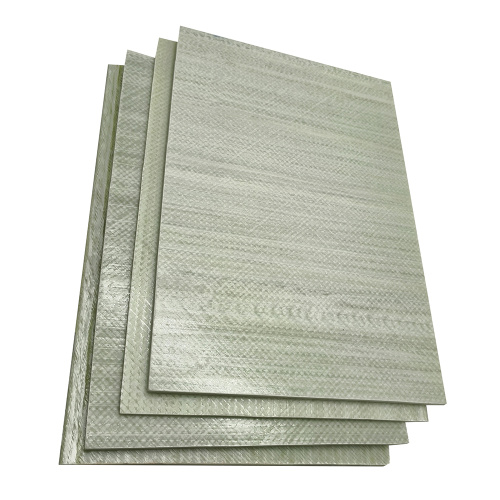

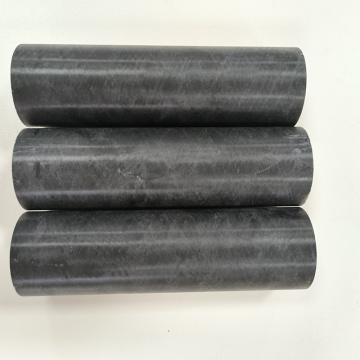

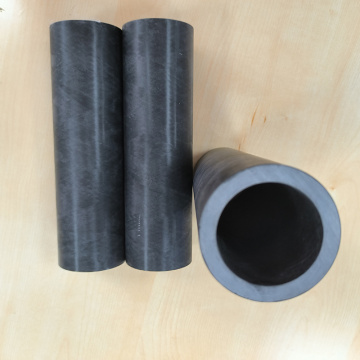

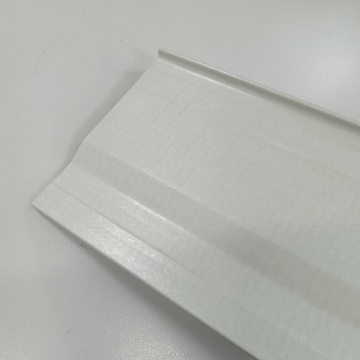

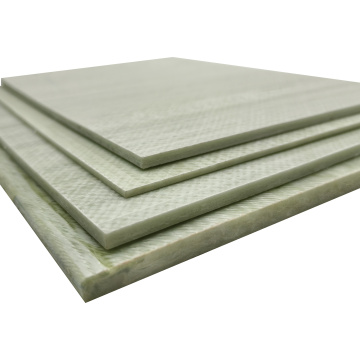

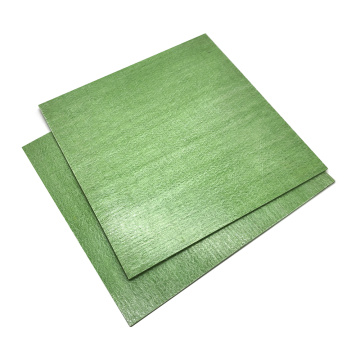

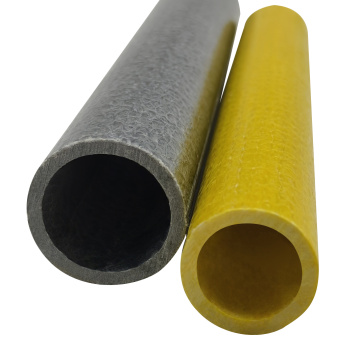

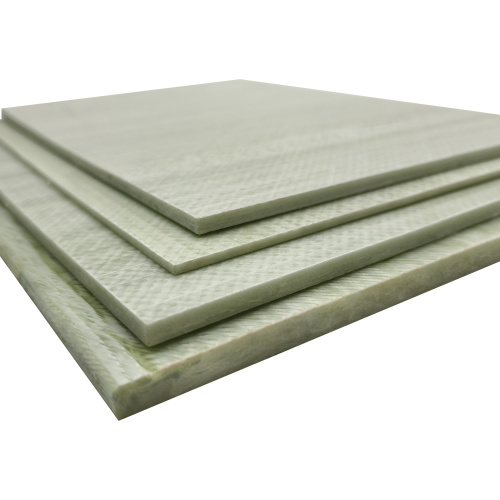

FRP plate (Fiber Reinforced Plastic), also known as fiberglass plate, is a high-performance material made of glass fiber as reinforcement material and resin as matrix. Among its components, glass fiber usually uses untwisted yarn fiber or continuous fiber to provide high-strength support; the resin matrix is mostly made of polyester, epoxy or vinyl ester, etc., which gives the material good formability and chemical resistance, and is supplemented with additives such as curing agent and ultraviolet absorber to optimize performance. According to the fiber type, FRP plates can be divided into glass fiber reinforced (GFRP), carbon fiber reinforced (CFRP) and aramid fiber reinforced (AFRP). Among them, GFRP is the most widely used due to its low cost and stable performance.

The performance characteristics of this material are remarkable: First, it is lightweight and high-strength, with a density of only 1/4-1/5 of that of steel, but a tensile strength close to or even exceeding that of carbon steel, and a specific strength better than alloy steel; second, it has outstanding corrosion resistance, can resist chemical erosion by acids, alkalis, salts, etc., and can adapt to harsh environments such as chemical and marine industries; third, it has both weather resistance and impact resistance, can withstand extreme temperature changes, ultraviolet rays, and wind and snow loads, the bending strength can reach 40-160MPa, and the light transmittance is as high as 82%-90%, which is suitable for building lighting and agricultural greenhouses; fourth, it has excellent electrical insulation and thermal insulation, low thermal conductivity, and meets flame retardant standards, and can be used in power facilities and fire prevention scenarios. In addition, its process is highly flexible, supporting a variety of forming methods such as pultrusion and compression molding, and more than 128 types of plate types can be customized to meet the diverse needs of construction, transportation, aerospace and other fields.

Our company focuses on the research and development and supply of high-performance engineering plastics and insulation materials. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

Related Keywords

Related Keywords