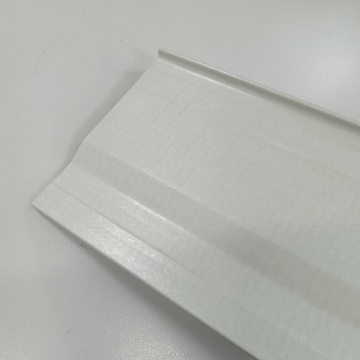

Lightweight & High-Strength FRP Fence Board

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

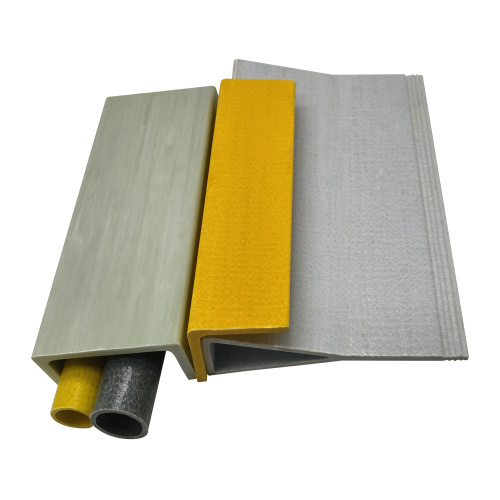

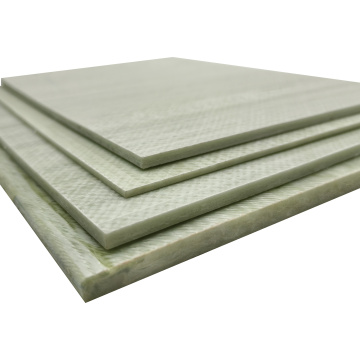

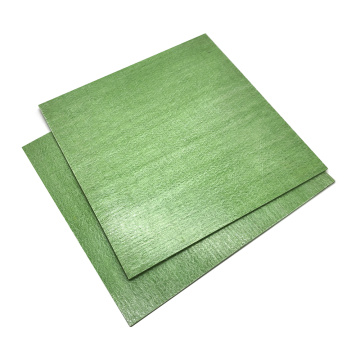

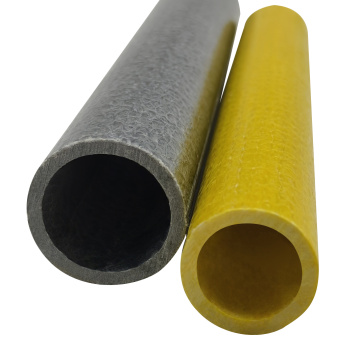

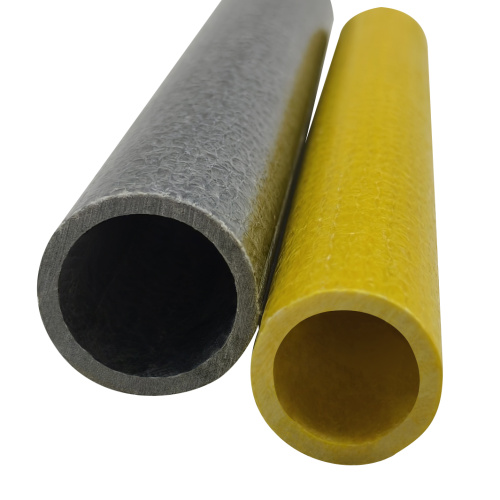

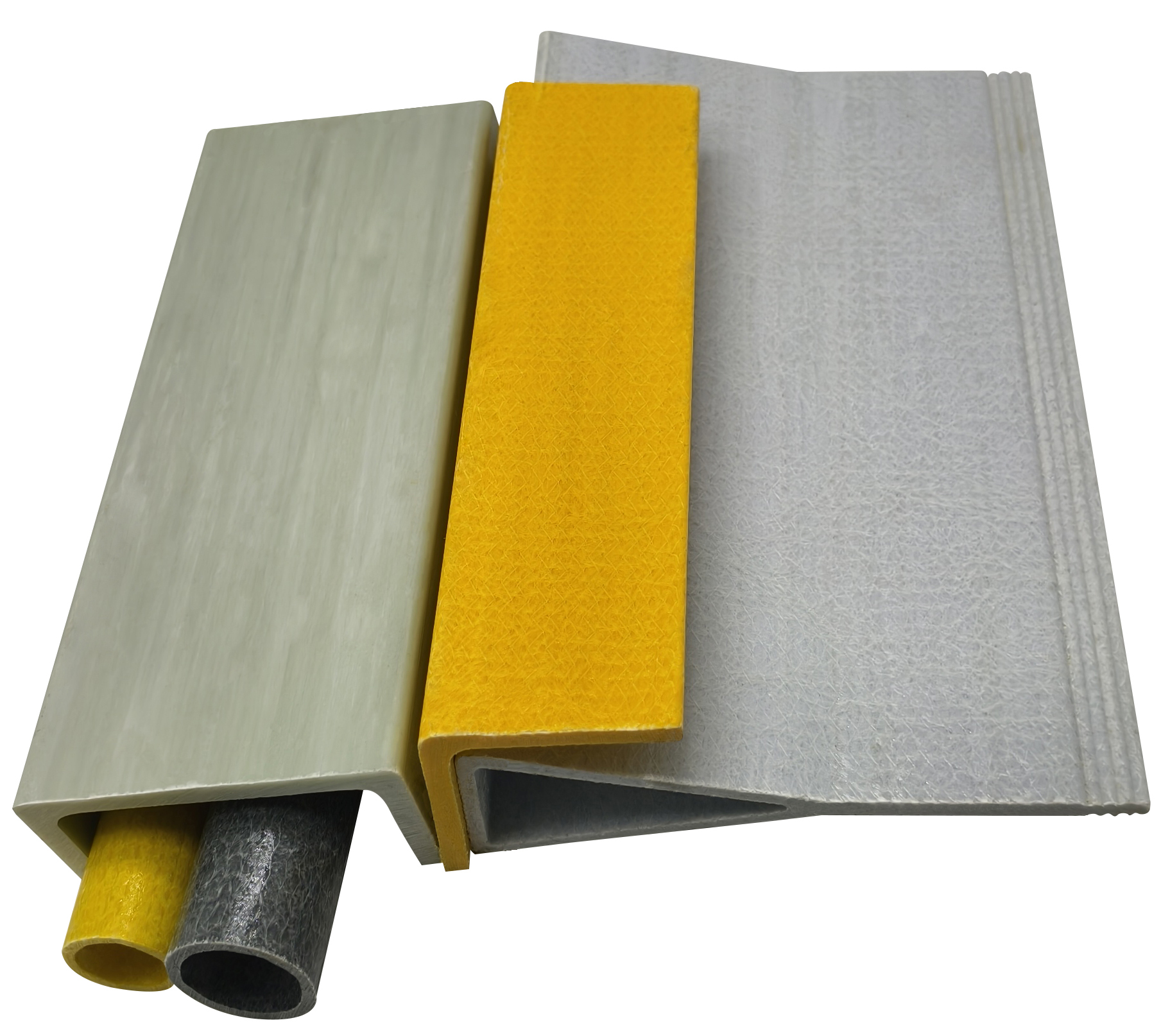

FRP plate (Fiber Reinforced Plastic), commonly known as FRP plate, is a high-performance material composed of fiber-reinforced materials and resin matrix. The composition design of FRP plate is flexible, and the fiber type, resin type and additives can be adjusted according to the application scenario (such as construction, shipbuilding, chemical industry) to balance the requirements of strength, corrosion resistance, cost, etc. The core features are light weight, high strength, corrosion resistance, and insulation, and are widely used to replace traditional metal materials. It has light weight and high strength performance.

1.High load-bearing capacity: uniform load distribution is achieved through structural design (such as the grid density of pultruded grids) to support heavy equipment or frequent trampling.

2.High strength: the fiber and resin composite process (such as pultrusion) ensures the material's impact resistance and bending resistance, and adapts to harsh industrial environments.

3.High wear resistance: surface resin coating or special treatment (such as anti-slip texture) extends service life and reduces maintenance costs

Application Scenario

1. FRP ladder

Scenario: chemical plants, power towers, ships and other high-altitude working environments.

Advantages:

Lightweight: 60% lighter than steel ladders, reducing installation difficulty and structural load.

Corrosion resistance: resist acid, alkali and salt spray corrosion, and avoid metal rust risks.

Insulation and anti-slip: ensure the safety of workers and are suitable for live environments.

2. FRP guardrail

Scenario: highways, bridges, chemical plant enclosure systems.

Advantages:

Wind pressure resistance: high-strength fiber layer resists strong wind impact and reduces deformation risk.

Maintenance-free: no regular anti-rust treatment is required, and the appearance integrity is maintained for a long time.

Light transmittance: optional translucent design (such as grille guardrail) to improve space lighting.

3. FRP platform

Scenario: offshore oil platforms, sewage treatment plant walkways, food workshops.

Advantages:

Anti-slip and wear-resistant: surface embossing or grille structure prevents slippery environment accidents.

Chemical corrosion resistance: Resistant to oil, strong acid and alkali cleaning agents, extending service life.

Modular installation: Standardized plate splicing, shortening construction period.

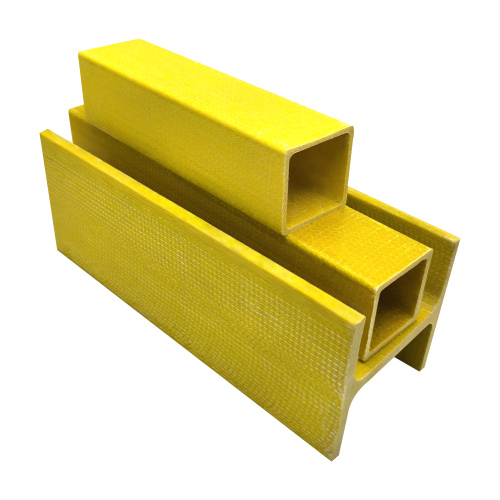

4. FRP pultruded grating

Scenario: Industrial trench cover, equipment maintenance channel, cooling tower bracket.

Advantages:

High load-bearing ratio: The load-bearing capacity exceeds that of steel at the same weight, reducing the overall structural load.

Water-permeable and breathable: The grid structure accelerates liquid discharge and avoids water corrosion.

Flame retardancy: Adding flame retardants such as aluminum hydroxide, it meets industrial fire protection standards.

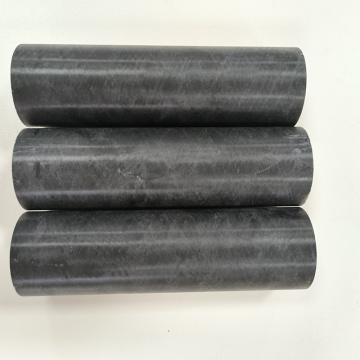

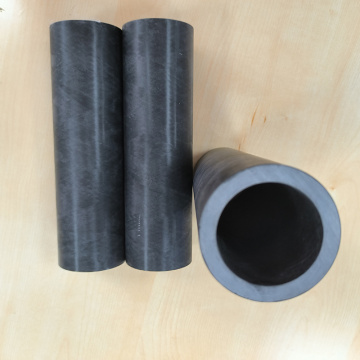

Our company focuses on the research and development and supply of high-performance engineering plastics and insulation materials. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

Related Keywords

Related Keywords