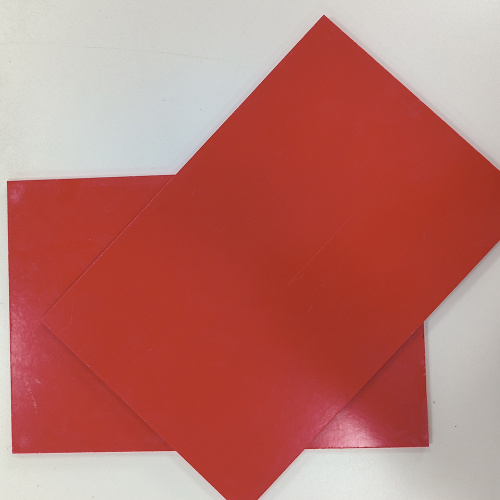

GPO-3 Unsaturated Polyester Glass Mat (EPGM203)

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Product Composition

The composition of UPGM203/GPO-3 unsaturated polyester glass fiber mat reinforced laminate is based on alkali-free glass fiber mat + unsaturated polyester resin, and functional additives are used to optimize flame retardancy, arc resistance and environmental protection performance. Its composition design is directly related to international standards (IEC 60893, UL 94 V-0), and strictly avoids harmful substances to ensure safety and reliability in high-voltage electrical appliances, UPS systems and other scenarios.

Performance Characteristics

1. Electrical insulation

Arc resistance ≥180 seconds, anti-tracking CTI ≥600V, high resistivity (volume ≥10¹⁰ Ω·m), dielectric strength ≥12 kV/mm.

2. Flame retardant and heat resistance

UL 94 V-0 grade self-extinguishing flame retardant, oxygen index ≥30%, combustion smokeless and halogen-free (in line with French NF standards).

Heat resistance 155°C, operating temperature range -273°C to +155°C, thermal shock resistance.

3. Mechanical and processability

High strength and impact resistance: bending strength ≥180 MPa, impact ≥60 kJ/m², dimensional stability (thermal expansion coefficient ≤21×10⁻⁶/K).

Easy to process: support stamping, CNC, etc., no stratification on the edge, suitable for automated production.

4. Safety and environmental protection

Halogen-free and low-toxicity: Passed RoHS/Reach certification, combustion without irritating gas

Advantages

1. Top electrical performance

Arc resistance ≥ 180 seconds, leakage resistance CTI ≥ 600V, dielectric strength ≥ 12 kV/mm, ensuring the insulation reliability of high-voltage equipment.

2. Flame retardant and heat resistant

UL 94 V-0 self-extinguishing flame retardant, smokeless and halogen-free combustion (NF certified), heat resistant to 155°C, working temperature range spanning -273°C to +155°C.

3. High strength and easy processing

Bending strength ≥ 180 MPa, impact resistance without cracking, dimensional stability (thermal expansion coefficient ≤ 21×10⁻⁶/K), supports efficient processing such as stamping and CNC.

4. Safety and environmental protection

Halogen-free and low-toxic, RoHS/Reach certified, burning without irritating gases, suitable for confined spaces.

Summary: With "electrical insulation + flame retardant and heat resistant" as the core, it has both strength and environmental protection, and is specially used in high-demand scenarios such as circuit breaker partitions, arc extinguishing covers, motor carbon brush holders, etc.

Application Fields

1. Circuit breaker components

Arc extinguishing system: arc extinguishing chamber arc isolation plate, phase partition (flame retardant V-0 level arc blocking)

Safety structural parts: safety baffles and spacer pads of frame-type circuit breakers (dimensional stability ensures precise assembly)

2. Motor and motor components

Stator/rotor components: slot wedges, fixed gaskets, carbon brush holders (impact resistance ≥60 kJ/m², vibration-proof and fragmentation-proof)

High-temperature components: movable cover plates, thin gaskets (heat-resistant 155℃ to adapt to high-temperature motor environments)

3. Switchgear and power transmission and distribution

Isolation support: busbar support, high-voltage insulator (CTI ≥600V leakage resistance, arc resistance ≥180 seconds)

Cabinet structure: switch cabinet partition, contact support (bending strength ≥180 MPa to ensure rigidity)

Summary: Core applications: Circuit breaker arc extinguishing, motor heat-resistant components, high and low voltage switch isolation Three major scenarios, using electrical insulation + mechanical support functions to solve the needs of high voltage, strong vibration, and high temperature working conditions.

Our company is deeply engaged in the field of high-performance engineering plastics and insulation materials, and is committed to providing innovative material solutions for the global high-end manufacturing industry. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance, and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

FAQ

Q: Can you provide samples? Is there a charge for samples?

A: Yes, we can provide small free samples, and the freight is paid by the buyer.

Q: How does your company ensure product quality?

A: Product quality is our primary concern. We have established a complete quality control system that runs through the entire process of raw material procurement, production process and final product inspection. We adopt strict standards and pass methods such as ISO9001 certification and multiple quality inspection processes to ensure that every product delivered to customers meets requirements and standards.

Q: How long does it usually take to deliver?

A: Generally, our standard delivery cycle is 7 to 30 days after receiving the deposit to confirm the order. Please note that the specific time will vary depending on the specific product model you ordered, the complexity of the process, and the order quantity. For customized products or large-volume orders, we will provide a more precise delivery schedule when confirming the order.

Q: How is the product packaging?

A: Conventional packaging is pallets for plates, wooden boxes for bars, cartons for processed parts or according to customer requirements.

Q: Can you cut or carve into the shape we want?

A: Yes. We have large cutting and engraving machines and can customize the processing.

Related Keywords

Related Keywords