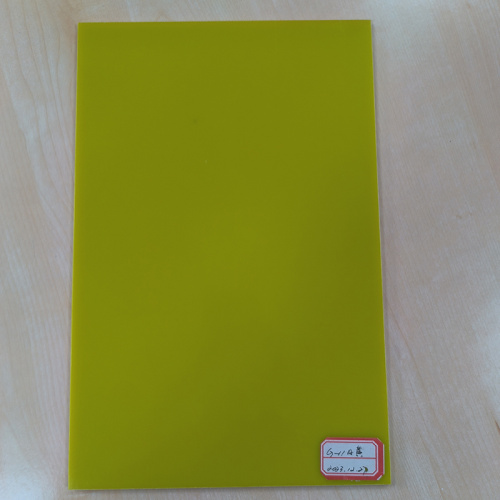

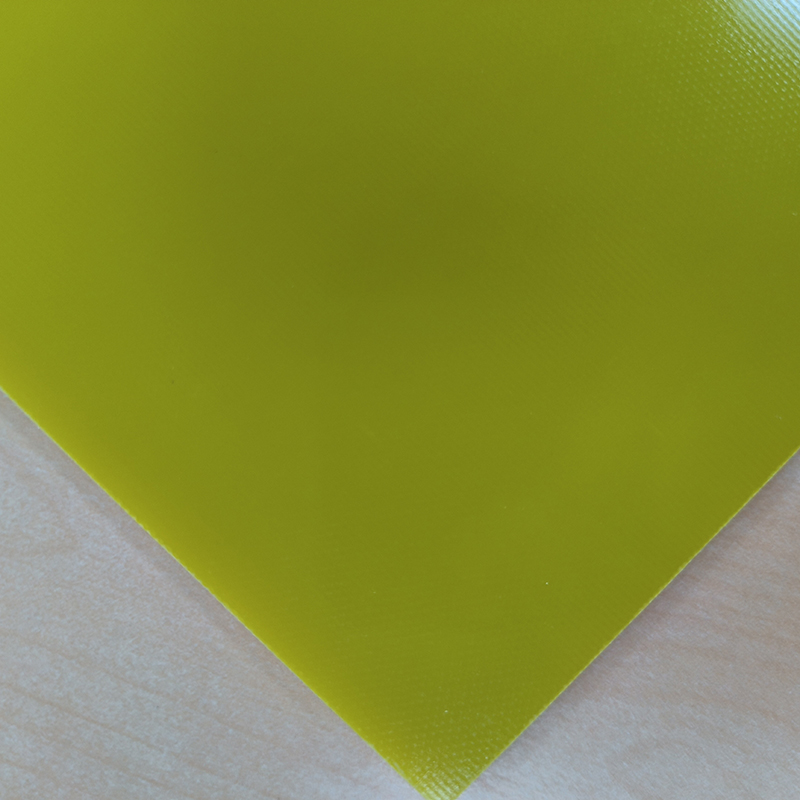

G11 Laminated Fiberglass Epoxy Sheet Electrical

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

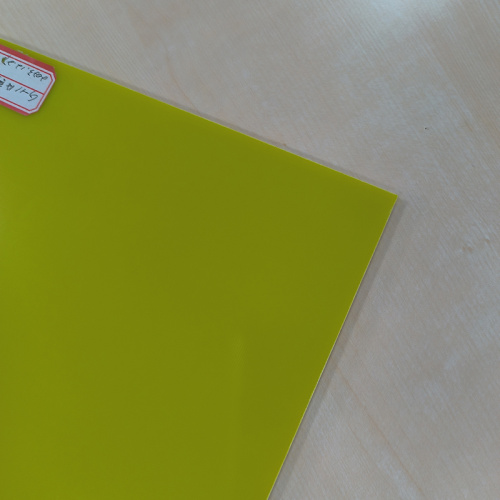

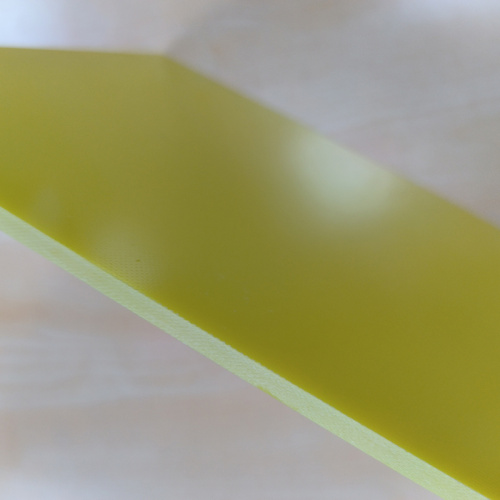

EPGC203 insulation material is made of electrical grade alkali-free glass fiber cloth as the base material, composite high TG (high temperature curing) epoxy resin as the adhesive, and is made through a 155℃ high temperature hot pressing lamination process.

Performance Characteristics

1. High mechanical strength: stable structure at room and high temperatures, strong load resistance.

2. Excellent insulation: stable electrical performance in dry and wet environments, high dielectric strength.

3. Strong environmental resistance: resistant to moisture, transformer oil corrosion, and adaptable to harsh working conditions.

4. F-grade heat resistance: long-term working temperature ≥155℃, in line with NEMA G11 standards.

5. Complete certification: passed GB/T 1303.4 and IEC 60893 standard certification.

Advantages

1. High-quality material composite

Electrical-grade alkali-free glass fiber cloth is combined with high TG epoxy resin to ensure high strength and heat resistance.

2. Strong weather resistance

Resistant to moisture and transformer oil corrosion, suitable for various harsh working conditions.

3. Standard certification

Certified by China GB/T 1303.4 and international IEC 60893 standards, quality is guaranteed.

4. Wide application

Applicable to various scenarios such as motors and high-voltage switches to meet diverse needs.

Application Fields

1. Motors and electrical equipment

As insulating structural parts, used for motor stators, rotor end plates, flanges, slot wedges and terminal blocks.

2. High-voltage switchgear

Applicable to insulation components of high-voltage switchgear and high-voltage switchgear.

3. Special working conditions

Can operate stably for a long time in humid environments and transformer oil immersion conditions.

Our company is deeply engaged in the field of high-performance engineering plastics and insulation materials, and is committed to providing innovative material solutions for the global high-end manufacturing industry. Our main products include high-end engineering plastic sheets/rods such as polyoxymethylene (POM), ABS, nylon (PA), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetheretherketone (PEEK), etc. We also provide special insulation materials such as bakelite (phenolic laminate) and epoxy glass fiber board. With excellent properties such as high temperature resistance, wear resistance, and high strength, our products are widely used in new energy vehicles, smart electronics, industrial machinery, aerospace and other fields.

Related Keywords

Related Keywords