High-Strength FR4 Epoxy Fiberglass Sheet for PCB Insulation

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

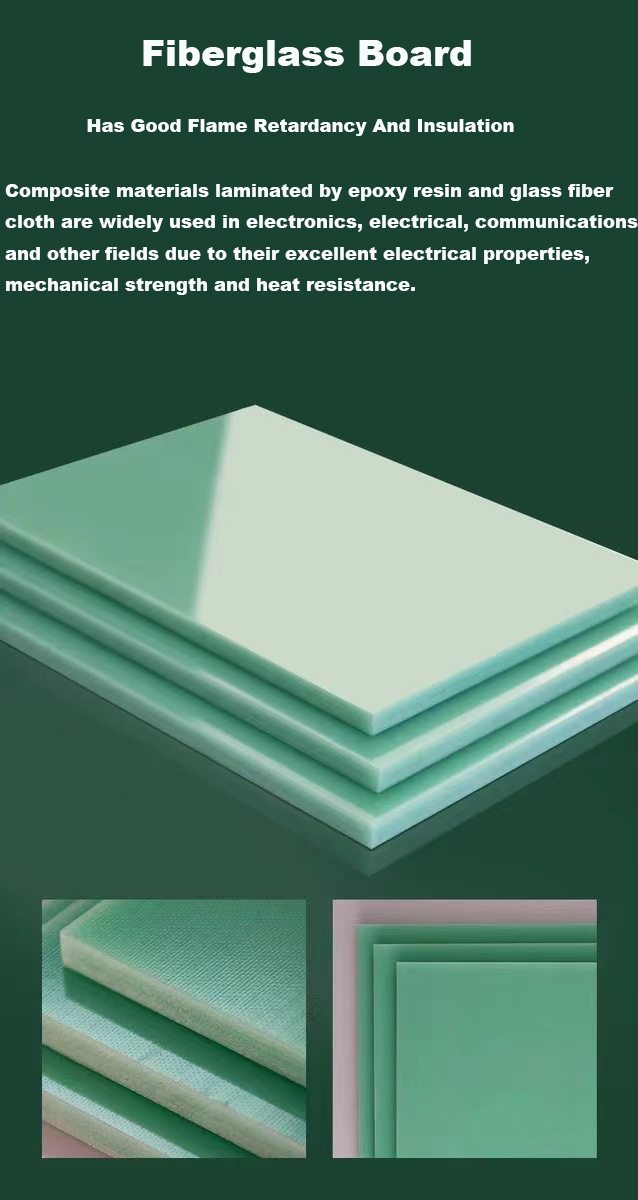

Composition FR4 (Flame-Retardant 4) is a composite material with glass fiber cloth as reinforcement material and epoxy resin as matrix, and is laminated through high temperature and high pressure process. Its core components include: Glass fiber cloth: provides mechanical strength and dimensional stability, and the woven structure enhances impact resistance. Epoxy resin: As an adhesive, it gives the material flame retardancy (UL94 V-0 grade) and chemical corrosion resistance. Flame retardant additives: ensure that the material self-extinguishes when burning and meets safety standards.

Electrical insulation: high insulation resistance, low dielectric constant, suitable for high-frequency circuits.

Mechanical strength: high bending strength and impact resistance.

Heat resistance: can remain stable at higher temperatures, usually 130°C to 140°C.

Flame retardancy: meets UL94 V-0 flame retardant standards and has good fire resistance.

Chemical resistance: good resistance to most chemicals.

Dimensional stability: can remain dimensional stable under changes in temperature and humidity.

Advantages

High performance: excellent electrical and mechanical properties, suitable for demanding applications.

Flame retardancy: meets strict flame retardant standards and is highly safe.

Versatility: suitable for a variety of electronic and electrical applications.

Processability: easy to cut, drill and surface treat.

Environmental protection: some products comply with environmental protection standards such as RoHS.

| Property | Bakelite sheet | FR4 sheet |

| Base Material | Phenolic resin + wood pulp/cotton fabric | Epoxy resin + glass fiber |

| Cost | Lower | Higher |

| Temperature Resistance | 100-130°C | 130-180°C (higher for epoxy board) |

| Electrical Performance | Medium/Low Voltage Insulation | High-Frequency/High Voltage Insulation (superior) |

| Typical Applications | Mechanical parts, medium/low voltage electrical devices | PCB substrates, high-end insulating components |

| Comparison Table: 3240 Epoxy Glass Sheet vs. FR4 Sheet | ||

| Characteristics | 3240 Epoxy Glass Sheet | FR4 Sheet |

| Main Applications | Structural insulation parts, mechanical support | Printed circuit board (PCB) substrate |

| Key Processing Techniques | Mechanical processing (cutting, drilling) | PCB processes (etching, copper plating, etc.) |

| Key Performance Focus | Mechanical strength, insulation | High-frequency signal transmission, dielectric stability |

| Typical Thickness | 0.5mm–50mm (thicker) | 0.2mm–3.2mm (thinner) |

Related Keywords

Related Keywords