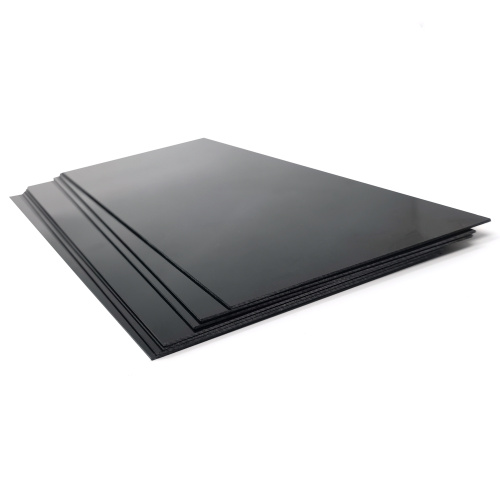

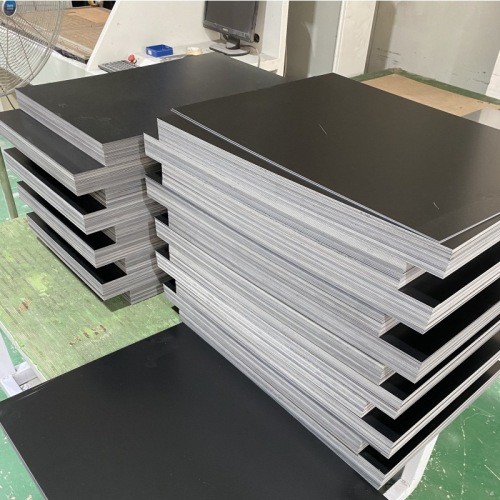

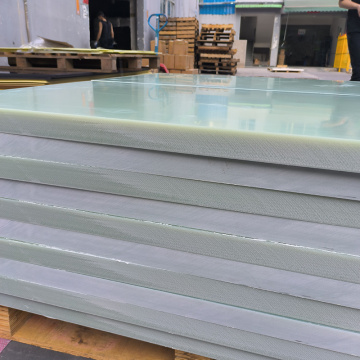

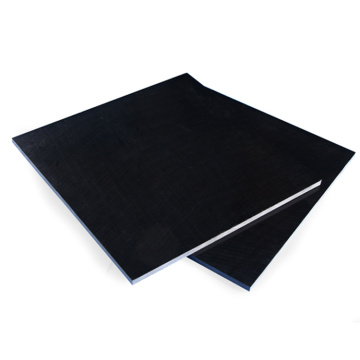

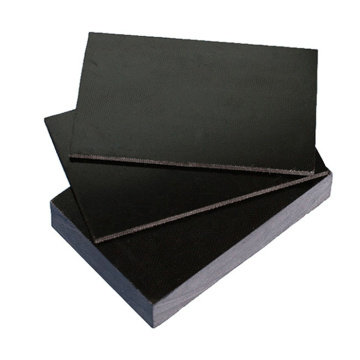

Black FR4 Fiberglass Epoxy Sheet for Battery Encapsulation

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 30Tons/month |

| Supply Ability: | 30Tons/month |

| Payment Type: | T/T,D/P,D/A,Paypal,Alipay/Wechat |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,Express Delivery,DDU |

| Certificate: | RoSH,SGS |

| HS Code: | 7019909990 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

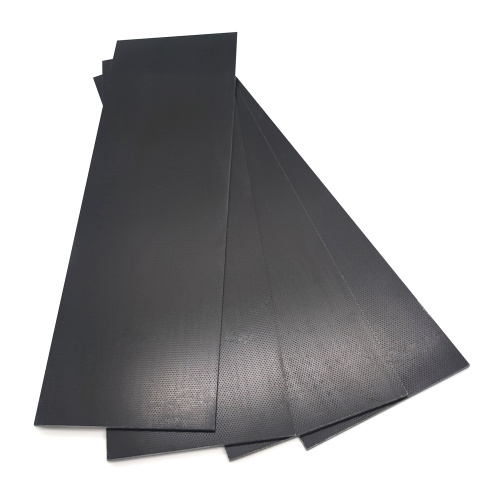

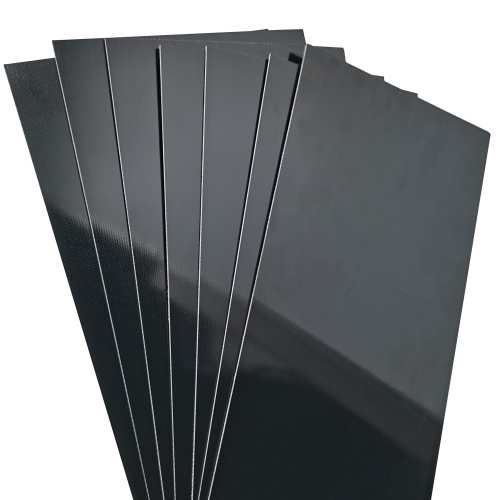

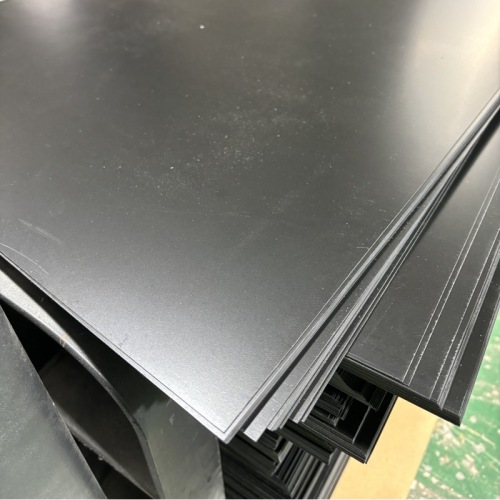

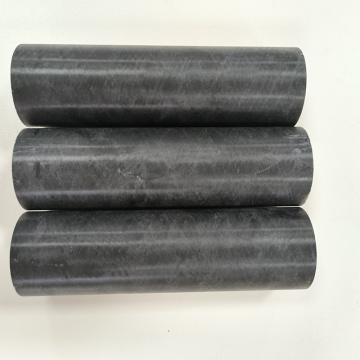

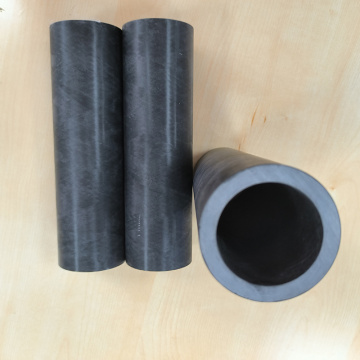

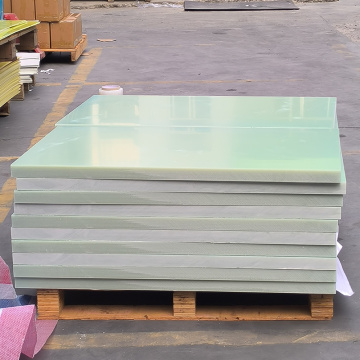

Black FR4 sheets are high-performance composite materials widely used in electronics, automotive, and industrial applications. Composed of woven fiberglass fabric impregnated with flame-retardant epoxy resin, these sheets are reinforced with a black-colored surface layer for enhanced aesthetics and UV resistance. The core structure ensures exceptional mechanical strength, thermal stability, and electrical insulation. FR4’s flame resistance (UL94 V-0 rating) and low moisture absorption (<0.1%) make it ideal for demanding environments. Its versatility supports applications such as printed circuit boards (PCBs), enclosures, and insulating components, where durability, safety, and precision are critical.

Composition & Manufacturing Process

Black FR4 sheets are produced through a precision-driven process. First, E-glass fiber fabric is coated with brominated epoxy resin (for flame retardancy) and blended with black pigments or surface-treated for color consistency. The resin-impregnated fabric is layered and subjected to multilayer lamination under high pressure (300–500 psi) and temperature (170–190°C). This cures the epoxy, forming a rigid, homogeneous structure. Post-lamination, sheets are precision-cut, polished, and tested for thickness tolerance (±5%), dielectric strength (>20 kV/mm), and thermal expansion (CTE <14 ppm/°C). Advanced quality control ensures compliance with international standards (IPC-4101, RoHS), guaranteeing reliability for high-frequency and high-temperature applications.

Applications of FR4 Sheets

Electronics: PCBs for consumer devices, telecom equipment, and IoT modules.

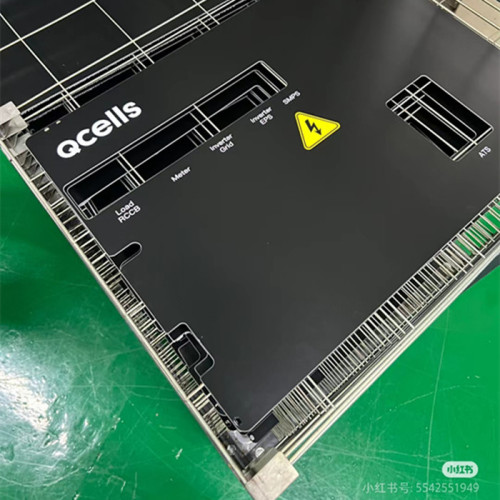

Automotive: ECU housings, sensor substrates, and EV battery insulation.

Industrial Machinery: Motor insulation, control panels, and transformer barriers.

Aerospace: Avionics systems and high-reliability circuit boards.

LED Lighting: Heat-resistant bases and driver boards.

Medical Devices: Diagnostic equipment and sterilizable components.

Renewable Energy: Solar inverters and wind turbine control circuits.

Related Keywords