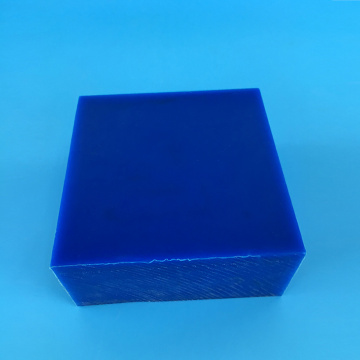

3240 Epoxy Glass Sheet Insulation High Strength

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Performance Characteristics

Mechanical properties: flexural strength 200-300MPa, compressive strength 300-600MPa, density 1.7-1.9g/cm³, with both lightweight and high strength characteristics, suitable for precision mechanical structural parts.

Electrical insulation: dielectric strength 40kV/mm, volume resistivity 10¹²-10¹⁴Ω·cm, excellent arc resistance, ensuring the safe operation of high-voltage equipment (such as transformers, switch cabinets).

Heat resistance characteristics: Class B temperature resistance (155℃), continuous working temperature 130℃, short-term tolerance 180℃, low thermal expansion coefficient, dimensional stability at high temperature.

Corrosion resistance and moisture resistance: acid and alkali/oil resistance, water absorption rate <0.3%, mildew and moisture resistance, outdoor use and UV aging resistance.

Easy to process: supports cutting/drilling/bonding;

Safety and environmental protection: passed UL94 V-0 flame retardant and RoHS/REACH certification, no toxic substances released.

Advantages

High insulation reliability: suitable for high-voltage electrical equipment, stable insulation performance, excellent arc resistance.

Outstanding mechanical strength: strong impact resistance and deformation resistance, suitable for structural support parts and wear-resistant parts.

Environmental adaptability: high temperature resistance, humidity resistance, corrosion resistance, can be used for a long time under harsh working conditions.

Cost-effectiveness: compared with special engineering plastics (such as PEEK), it is cheaper and more cost-effective.

Application Fields

1. Electrical insulation field

Motors and transformers: used as motor slot wedges, transformer insulation pads, coil skeletons, etc.

High-voltage equipment: circuit breaker insulation plates, switch cabinet supports.

2. Mechanical structure field

Fixtures: insulation pads and mold substrates in precision machining (due to low deformation rate).

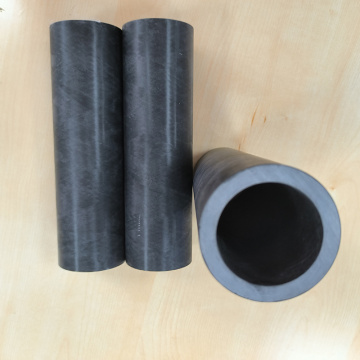

Wear-resistant parts: gears, bearing bushings (scenarios that require wear resistance and insulation).

3. Electronic equipment

Heat dissipation substrate: insulation heat dissipation substrate for high-power electronic components (such as IGBT modules).

PCB auxiliary materials: test fixtures, drilling pads (taking advantage of their high flatness and high temperature resistance).

4. Special industries

Railway transportation: high-speed rail/subway insulation components (such as pantograph insulation support).

New energy: wind power converter insulation structural parts, photovoltaic inverter bracket.

Related Keywords

Related Keywords