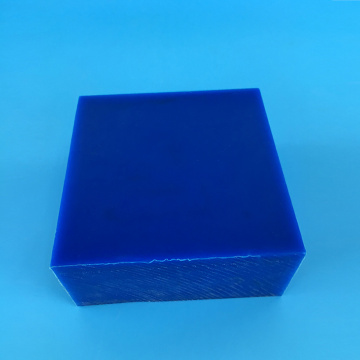

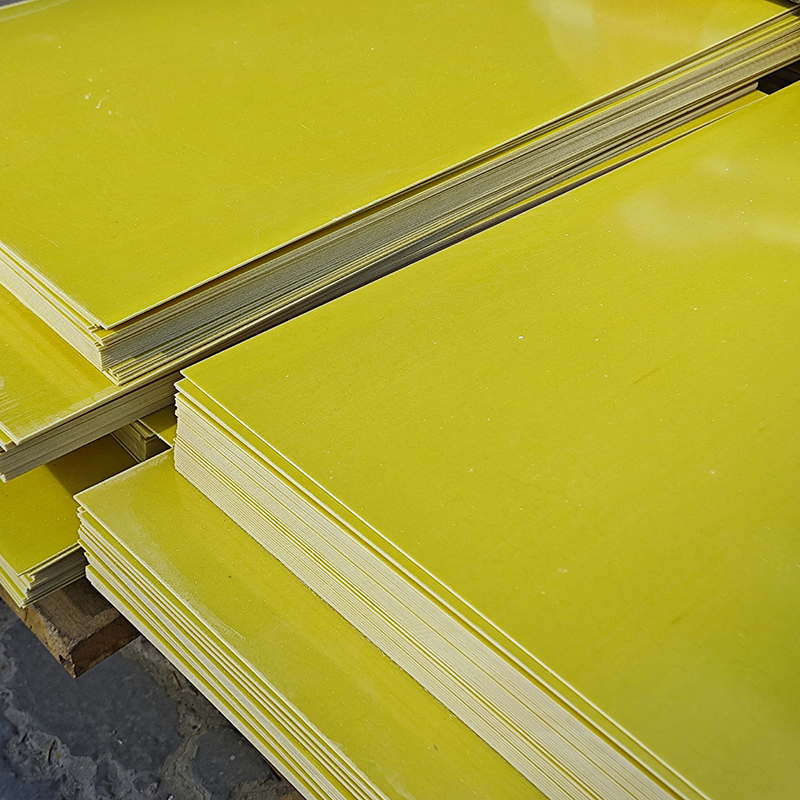

Precision Cut 3240 Epoxy Sheet Electrical Insulation

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Performance characteristics:

Good insulation, high voltage resistance, dielectric strength of about 20kV/mm.

High mechanical strength, tensile and bending strength both exceed 200MPa.

Good heat resistance, long-term temperature resistance of 130℃, heat deformation temperature exceeds 200℃.

Strong environmental resistance, low water absorption (<0.1%/24h), chemical corrosion resistance.

Product advantages:

Lightweight and high strength, excellent processability, customizable shape.

High cost-effectiveness, high cost-effectiveness throughout the life cycle.

Application areas:Electronic and electrical: printed circuit boards, insulating components, etc.

Industrial manufacturing: mechanical parts, chemical equipment components, etc.

Aerospace: interior panels, radar covers, etc.

Transportation: automotive and ship parts

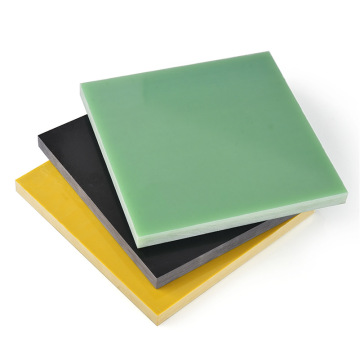

| Comparison Table: 3240 Epoxy Sheet vs. FR4 Sheet | ||

| Characteristics | 3240 Epoxy Sheet | FR4 Sheet |

| Main Applications | Structural insulation parts, mechanical support | Printed circuit board (PCB) substrate |

| Key Processing Techniques | Mechanical processing (cutting, drilling) | PCB processes (etching, copper plating, etc.) |

| Key Performance Focus | Mechanical strength, insulation | High-frequency signal transmission, dielectric stability |

| Typical Thickness | 0.5mm–50mm (thicker) | 0.2mm–3.2mm (thinner) |

Temperature Resistance: It has a temperature resistance rating of B, maintaining high mechanical strength at room temperature up to 130°C.

Electrical Properties: It exhibits excellent electrical properties in both dry and wet conditions, and it is flame-resistant.

Application Areas: It is mainly used in electrical and electronic industries for insulation structural components.

Features: It has strong adhesion, easy curing, good mechanical properties, diverse forms, and low shrinkage.

FR4 Sheet:

High-Temperature Resistance: It has excellent high-temperature resistance, enduring temperatures up to 180°C.

Corrosion Resistance: It can resist erosion from most chemicals, resulting in a long service life.

Mechanical Strength: It has high mechanical strength, resisting external impacts and vibrations.

Electrical Insulation: It provides good electrical insulation, effectively preventing current leakage and electromagnetic interference.

Dimensional Stability: It maintains good dimensional stability during manufacturing, minimizing deformation.

Environmental Friendliness: It is made from environmentally friendly materials,( 68336747,non-toxic and harmless).

Application Areas: It is widely used in electronics, electrical engineering, communications, aerospace, and other fields, such as computer motherboards and power adapters.

G10 Sheet:

Temperature Resistance: It has a temperature resistance of up to 200°C, making it an excellent insulation board.

Features: It has diverse forms, easy curing, strong adhesion, and low shrinkage.

Application Areas: While its performance is superior, it has not been widely adopted due to price considerations. It has some applications in the aviation, aerospace, construction, chemical, and agricultural industries.

In summary, the 3240, FR4, and G10 boards differ in terms of temperature resistance, electrical properties, mechanical strength, electrical insulation, and other aspects, making them suitable for unique applications depending on specific needs and conditions.

Related Keywords

Related Keywords