Food Grade different size Silicone/rubber Viton O ring / Sealing rubber Ring Manufacturer

- Delivery Time:

- 7 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China (Mainland) |

|---|

Heat resistance & oilproof sealed waterproof soft sealing silicone rubber colored O rings for equipments gasket 1. Customized size & color

Heat resistance & oilproof sealed waterproof soft sealing silicone rubber colored O rings for equipments gasket 1. Customized size & color 2. Good air-proofness & oil resistance

3. Hardness: 30~80 shore A Rubber NBR O Ring Nitrile (or NBR) O-Rings are most commonly available and are cost effective. Ideal for use as seals on pumps, drive belts, and other general engineering applications.NBR is good for applications that need to withstand fats, Greases and high temperature (+70°C). Temperature Range -30°C to +120°C (avoid prolonged use at higher extremes) Suitable for: Many hydrocarbons, fats, oils gasoline, petroleum based hydraulic fluid etc

Mechanical Properties | |

Colour | Black or colours |

Material | Nitrile (NBR) |

Cross Section Type | Circular |

O-ring type | AS568,JIS, BS,EN Standard. |

Hardness (Shore A) | 65-75 |

Operating Temperature Range (°C) | "-30 to +120" |

Tensile Strength(MPA) | 14 |

Elogation At Break(%) | 385 |

Specific Gravity | 1.2 |

Mechanical Properties | |

Colour | Black or colours |

Material | Viton(FKM) |

Cross Section Type | Circular |

O-ring type | AS568,JIS, BS,EN Standard. |

Hardness (Shore A) | 65-75 |

Operating Temperature Range (°C) | "-20 to +210" |

Tensile Strength(MPA) | 12 |

Elogation At Break(%) | 210 |

Specific Gravity | 1.85 |

Mechanical Properties | |

Colour | Black or colours |

Material | EPDM |

Cross Section Type | Circular |

O-ring type | AS568,JIS, BS,EN Standard. |

Hardness (Shore A) | 65-75 |

Operating Temperature Range (°C) | "-40 to +140" |

Tensile Strength(MPA) | 14 |

Elogation At Break(%) | 385 |

Specific Gravity | 1.2 |

Mechanical Properties | |

Colour | Black or colours |

Material | HNBR |

Cross Section Type | Circular |

O-ring type | AS568,JIS, BS,EN Standard. |

Hardness (Shore A) | 65-75 |

Operating Temperature Range (°C) | "-45 to +150" |

Tensile Strength(MPA) | 14.8 |

Elogation At Break(%) | 425 |

Specific Gravity | 1.2 |

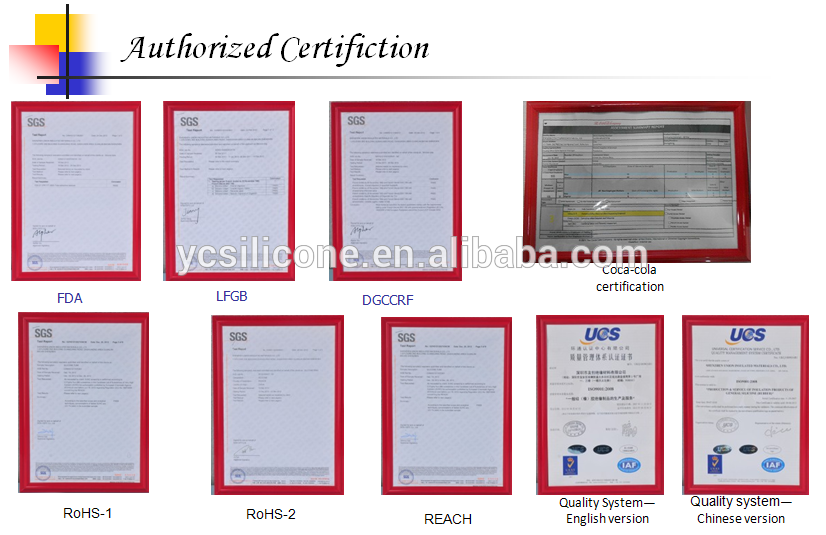

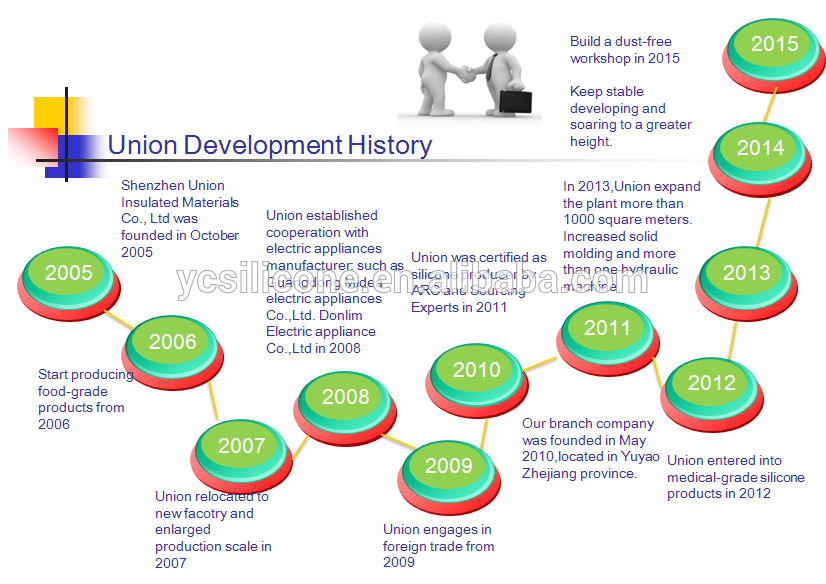

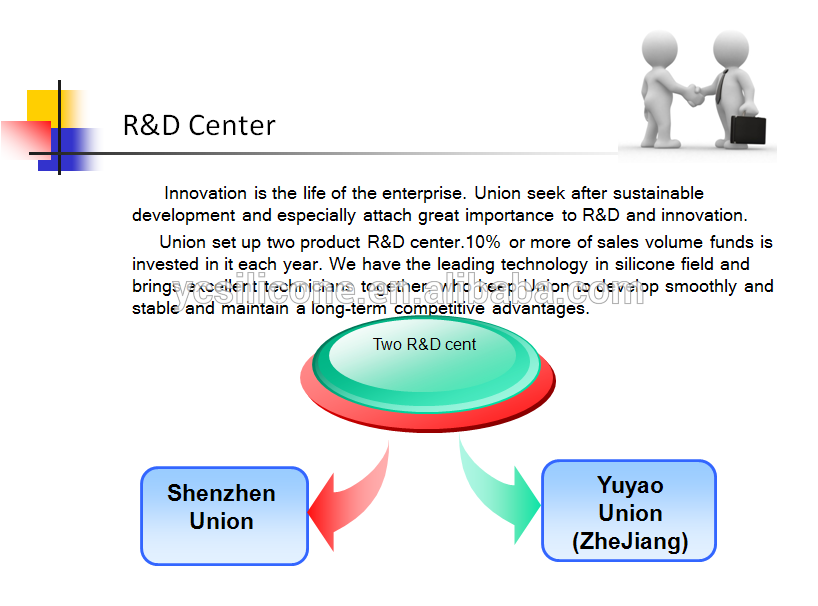

Company Information

Company Information

Our Services 10 years experience in manufacturing silicone (rubber) products. We are always available to discuss customer’s requirements and insure full customer’s satisfaction. Please feel free to contact us right now. We do will reply your inquiry in 24 hour More products:

Our Services 10 years experience in manufacturing silicone (rubber) products. We are always available to discuss customer’s requirements and insure full customer’s satisfaction. Please feel free to contact us right now. We do will reply your inquiry in 24 hour More products:

We are reliable supplier of silicone parts for the below major customers.

We are reliable supplier of silicone parts for the below major customers.  FAQ 1.Q:Are you a factory or trading company? A:We are a factory. 2.Q:Where is your factory located? How can I visit there? A:Our factory is located inShenzhen,Guangdong Province, China. All our clients, from home or abroad, are warmly welcomed to visit us! 3.Q:What is the material of your products A: We could make the products according to your requirement. 4.Q:How can I get some samples? A: We are honored to offer you samples for free.

FAQ 1.Q:Are you a factory or trading company? A:We are a factory. 2.Q:Where is your factory located? How can I visit there? A:Our factory is located inShenzhen,Guangdong Province, China. All our clients, from home or abroad, are warmly welcomed to visit us! 3.Q:What is the material of your products A: We could make the products according to your requirement. 4.Q:How can I get some samples? A: We are honored to offer you samples for free.

Related Keywords