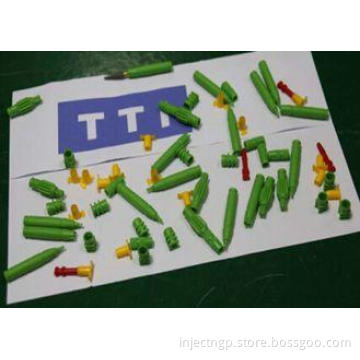

Injection Molded Plastic Parts For Precision Threaded tubes

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|

Injection Molded Plastic Parts For Precision Threaded tubes & Tranparent Mini Parts

TTi Service For Precision Plastic Injection Molding Production Description:

|

Plastic material |

Nylon, Nylon+GF, ABS, PC, PC/ABS, PBT+GF, PP, POM, PMMA&etc |

|

3D Design Software |

Solid works, NX, Pro-E, Auto-CAD(NX, Master CAM) for CAM Software |

|

Mold Application |

Automotive,electronic,industrial,architectural,medical,consumer & etc |

|

Product Type: |

Precision Injection Molding products for cars spare parts |

|

Mold Cavity |

Multi-cavities and Single cavity according to your budget |

|

Hot Runner |

MOLDMASTERS, YUDO, HASCO, DME, INCOE, SYNVENTIVE |

|

Standard |

HASCO, LKM, DME |

|

Mold life |

300,000-3,000,000 shots |

|

Molding machines |

20 injection machines from 50-160tons |

What we offer:

- Plastic precision injection molding & insert molding

- Multi-cavity mold & single cavity mold & products

- Plastic over-molding mold & double color injection mold

- Family mold tooling & products

- Hot runner mold tooling & products

- Tooling assembly and product assembly

- Secondary Operations

- Rapid prototyping tooling & product production

- Product Assembly

- OEM or ODM service

Custom Plastic Injection Molding Applications:

l Injection molded household utility products

l Plastic injection molded auto components

l Plastic molded electronic enclosures

l Plastic molds for medical & dental products

l Injection molding parts for model shops, toys

l Injection plastic parts for new product design & development

l Custom plastic parts for construction

l Customized injection molds for military spare parts

l Plastic injection for Information Technology

l Molded plastic parts for payment system

l Precision plastic parts for Agricultural equipment

l Injection plastic parts for others like cosmetic case

Process steps:

|

Quotation |

We will send the report if the plastic product can not be done on mold |

|

Negotiation |

Mold & plastic material, cavity number, payment terms, etc |

|

Purchase Order |

Send us Purchase Order accordingly and make the Deposit |

|

Mold design |

We will send customer mold design for approval when finished |

|

mold making |

Start the plastic tooling after the plastic part 3D design approval |

|

Mold processing |

Send report to customer each week |

|

Mold trial |

Send plastic trial samples and try-out report to customer for testing |

|

Parts Production |

Make plastic parts production after the trial sample approval |

|

Production Delivery |

Pack the plastic parts after QA check before shipping |

Competitive Advantage:

1. Strict quality control, and the factory has the most advanced testing equipment to ensure the precision of the mold.

2. 8 years experience on providing one-stop services( plastic part design---rapid prototype---mold making---production---delivery);

3. Long term cooperation with some Top Brand Auto Industry, such as Volvo and SKODA;

4. Short lead time and on time delivery.

5. Good After-sale service

plastic injection molding, injection molded products, custom plastic parts