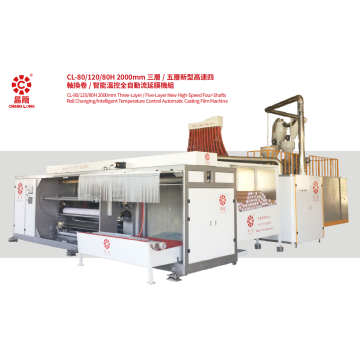

High Speed Stretch Film Plant For Big Jumbol

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 420kg/h |

| Supply Ability: | 1-50sets/m |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE,ISO90001:2008 |

| HS Code: | 8477800000 |

| Transportation: | Ocean |

| Port: | Shenzhen |

If you're dealing with big volumes of stretch film and need it fast, this High Speed Stretch Film Plant For Big Jumbo Rolls is likely what you're looking at. Falling under the Jumbo Roll Stretch Film Machine category, this isn't for small-time operations. We're talking about a powerhouse built for producing massive rolls of stretch film – the kind that keeps big industries running smoothly.

What's the "Jumbo" All About?

Think of your regular roll of stretch film, the kind you might use in a warehouse. Now imagine a roll so big it could practically have its own zip code! That's a jumbo roll. These super-sized rolls of stretch film, designed for high-volume users who go through a lot of material, are the primary output of this big roll stretch film machine.

Once the film is formed and cooled, it goes through various stages, which might include:

Thickness Control: Ensuring the film is consistently the desired thickness.

Edge Trimming: Removing any uneven edges to create clean rolls.

Winding: This is where the magic of the "jumbo" happens. The film is wound onto large cores, creating those massive rolls of stretch film. This automated winding process is crucial for any efficient stretch film roll making machine, especially one designed for such large outputs.

What Kind of Film Does It Make and What's It Used For?

Produce high volumes of PE stretch film, which is the workhorse of the packaging industry. You'll find this film being used for:

Pallet Wrapping (on a massive scale): Large distribution centers, manufacturing plants, and logistics companies rely on jumbo rolls to efficiently wrap and secure huge numbers of pallets for shipping and storage. Using jumbo rolls, produced by a dedicated Jumbo Roll Stretch Film Machine, means fewer roll changes on their wrapping machines, saving time and increasing productivity.

Industrial Packaging: Wrapping large or irregularly shaped items for protection during transport or storage.

Automated Wrapping Systems: Jumbo rolls are specifically designed to feed into automated stretch wrapping machines that handle high-throughput packaging lines.

You might be able to

Adjust Film Thickness: Depending on the specific model and its capabilities, you might have control over the thickness of the film being produced. Thicker film offers more strength, while thinner film can be more cost-effective for lighter loads.

Modify Film Width: The width of the jumbo rolls produced might be adjustable to suit different wrapping equipment and applications.

Potentially Add Layers (though not explicitly mentioned): While the keywords don't highlight co-extrusion (making multi-layered films), some advanced jumbo roll plants might have the capability to produce films with a few layers for enhanced properties. This would be a key question to ask the manufacturer of any big roll stretch film machine.

Integration with Other Equipment: The plant would likely be designed to integrate seamlessly with other parts of a large-scale packaging operation.

Investing in a High Speed Stretch Film Plant For Big Jumbo Rolls is a strategic move for businesses with significant stretch film needs. The benefits include:

High Production Capacity: The "high speed" aspect means you can produce a massive amount of stretch film in a shorter period, meeting large demands efficiently.

Cost Savings (in the long run): While the initial investment is substantial, producing your own jumbo rolls can significantly reduce the cost per unit of stretch film compared to buying pre-made jumbo rolls.

Reduced Downtime for End Users: For companies using these jumbo rolls, the larger size means fewer roll changes on their wrapping equipment, leading to less downtime and increased productivity on their packaging lines.

Consistent Supply: Having your own production capability ensures a reliable and consistent supply of stretch film, reducing reliance on external suppliers and potential supply chain disruptions.

Potential for Customization (as mentioned above): Depending on the plant's features, you might have more control over the specifications of the film you produce.

This High Speed Stretch Film Plant For Big Jumbo Rolls is a serious piece of industrial equipment designed for high-volume production of PE stretch film in massive, jumbo-sized rolls. Utilizing the cast film process, it ensures good quality and clarity. It's an ideal investment for large-scale operations that require a constant and reliable supply of stretch film for efficient pallet wrapping and industrial packaging. For any business looking into a dedicated stretch film roll making machine for large-scale output, this type of plant is a prime consideration.

High Speed Stretch Film Plant For Big Jumbol

1.The unit uses a melt metering pump with a precision sensing pressure system to strictly control the output of the extruder to ensure stablefilm extrusion and uniform extrusion.

2.The cooling roller adopts a large-diameter special flow path roller to improve the cooling effect in high-speed production and ensure uniform temperature of the surface of the cooling roller.

3.The entire production line realizes fully automated production, On the basis of the original automatic material change and reeling,the automatic paper feeding tube and the automatic unloading finished system are added to ensure high quality and stable production,which greatly saves the labor cost of production.

Application :2000mm Food Wraping Film Making Line

Pallet packaging, carton packaging, wrapping bulk goods, daily necessities packaging

Certificates

Packing

Company View:

Related Keywords