1500mm Two-Layer/ Three-Layer Automatic Co-Extrusion Casting Film Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Incoterm: | FOB |

|---|---|

| Transportation: | Ocean |

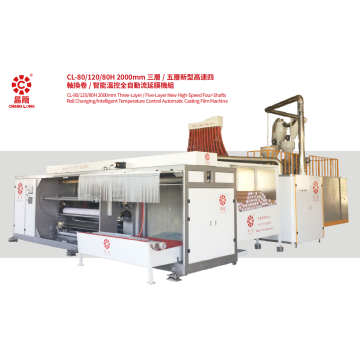

1500mm Two-Layer/Three-Layer Automatic Co-Extrusion Casting Film Machine

Unlock the potential of your packaging operations with our cutting-edge 1500mm Two-Layer/Three-Layer Automatic Co-Extrusion Casting Film Machine. Designed to accommodate a range of packaging needs with its substantial 1500mm production width, this machine is perfect for businesses looking to elevate their productivity and quality in film production.

Key Features and Benefits

Versatile Production: Capable of producing both two-layer and three-layer films, this flexible machine allows you to adapt your output according to the specific requirements of your products, including specialized applications using the 1500MM Plastic Stretch Film Machine Unit.

Automatic Operation: Experience seamless, efficient operations with an automated system that reduces labor costs and minimizes the risk of errors, ensuring a smooth production flow akin to what is delivered by the 1500MM Packaging Stretch Film Machine Unit.

High-Speed Production: With the capability to meet demanding schedules, this machine enhances your productivity, much like the 1500MM Black Stretch Film Machine Unit, enabling rapid output without compromising on film quality.

Superior Film Quality: Leverage advanced co-extrusion technology for precise control over film thickness, clarity, and strength. The end result is a superior quality film that provides robust protection and attractive presentation, characteristics shared by the 1500MM Hand Stretch Film Machine Unit.

How It Works

This advanced machine utilizes a co-extrusion process that melds multiple layers of plastic resin into a single, high-performance film. Customize the layers to impart specific properties to the film, such as increased strength for industrial packaging, enhanced clarity for consumer goods, or improved barrier protection for food products.

Ideal Applications

Packaging: Ensure excellent protection during storage and transportation, crucial for maintaining the integrity of consumer and industrial products.

Food Packaging: Utilize specialized stretch films for food products to maintain freshness and prevent contamination.

Industrial Packaging: Create films that hold up under the rigorous demands of securing and protecting heavy-duty items during storage or transport.

Upgrade Your Production Process

Investing in the 1500mm Two-Layer/Three-Layer Automatic Co-Extrusion Casting Film Machine means elevating your production capabilities to new heights. With its state-of-the-art features and efficient operation, you can significantly reduce costs, enhance productivity, and consistently produce high-quality films that fully meet the dynamic needs of your business. Opt for this machine to transform your production process and achieve outstanding results across various packaging applications.

1. The alloy screw adopts special mixing function and high plasticizing capacity to ensure good plasticization, uniform color and greatly improved extrusion.

2. The diameter of the cooling roller is increased, and the internal double-loop desien and built-in spiral flow path ensure uniform temperature oft he roller surface.

3. The winding frame adopts the middle aisle platform to facilitate the monitoring of the thickness and adjustment of the film on the line. The cutting knives can be replaced, and the double-sided non-stop cutting knives can be realized, which is safe and easy to operate.

Related Keywords