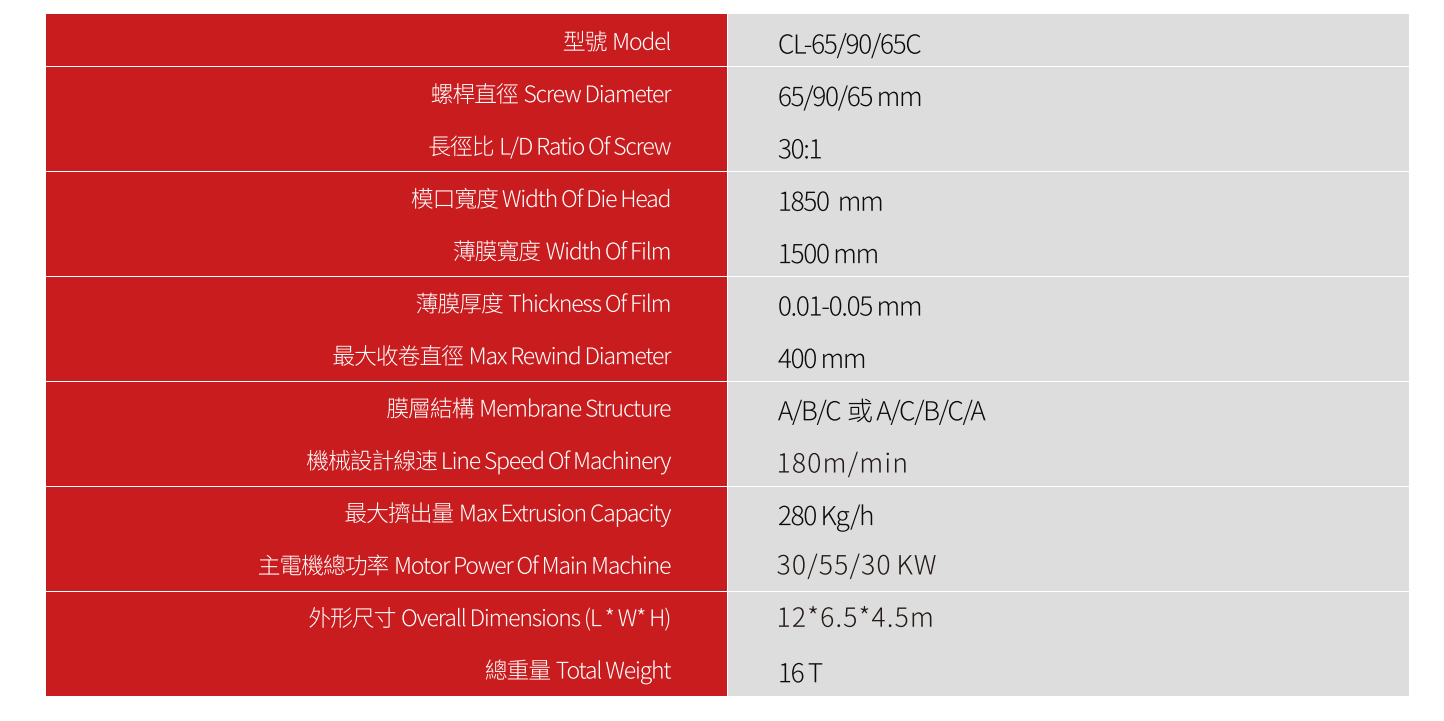

1500mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic Cling Film Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Transportation: | Ocean |

|---|

1. The cooling roller adopts a large-diameter special flow path roler to improve the coloing effect in high-speed production and ensure uniform temperature of the surface of the cooling roller.

2. The special alloy screw design adopts high plasticization and crystal point treatment structure to ensure that the extruded film is more stable, uniform high transparency, strong tensile force and better viscosity.

3. The entire production line realizes fully automated production, on the basis of the original automatic material change and reeling, the automatic paper feeding tube and the automatic unloading finished system are added to ensure high quality and stable production, which greatly saves the labor cost of the production.

4. The whole machine parts and electric control parts are all made of famous brand products to ensure stable operation and low failure rate.

5. The unit uses melt metering pump technology with a precision sensing force system for stable and efficient pressure control, which greatly increases the longitudinal and lateral tensile forces of the membrane and the puncture resistance of the film. Making the finished produce more rigorous to meeithe strict requirements ofthe machine film.

6. The unit utilizes melt metering pump technology with a precision sensing system. It is able to control the pressure stably and efficiently, which greatly improves the longitudinal and transverse tensile strength of the film as well as the puncture resistance of the film. The finished product is more likely to meet the strict requirements of the machine membrane.

7. This equipment can produce 8 microns cling film.

Related Keywords

-

2000mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

2000mm Three-Layer Automatic Swing Arm High-Speed Stretch Film Machine

2000mm Three & Five-Layer High-Speed Four Shafts Roll Changing Intelligent Temperature Control Automatic Casting Film Machine

New Type Four-Shafts Roll Changing Casting Film Machine

Intelligent Automatic High-Speed Casting Film Machine